Aluminum-plastic cover film for blister packaging easy for cursor positioning and cutting and preparation method thereof

A blister packaging and cursor positioning technology, applied in the field of pharmaceutical packaging, can solve problems such as unfavorable environmental protection, unfavorable cutting, elongated cursor, etc., and achieve the effects of saving heat energy and reducing solvent emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

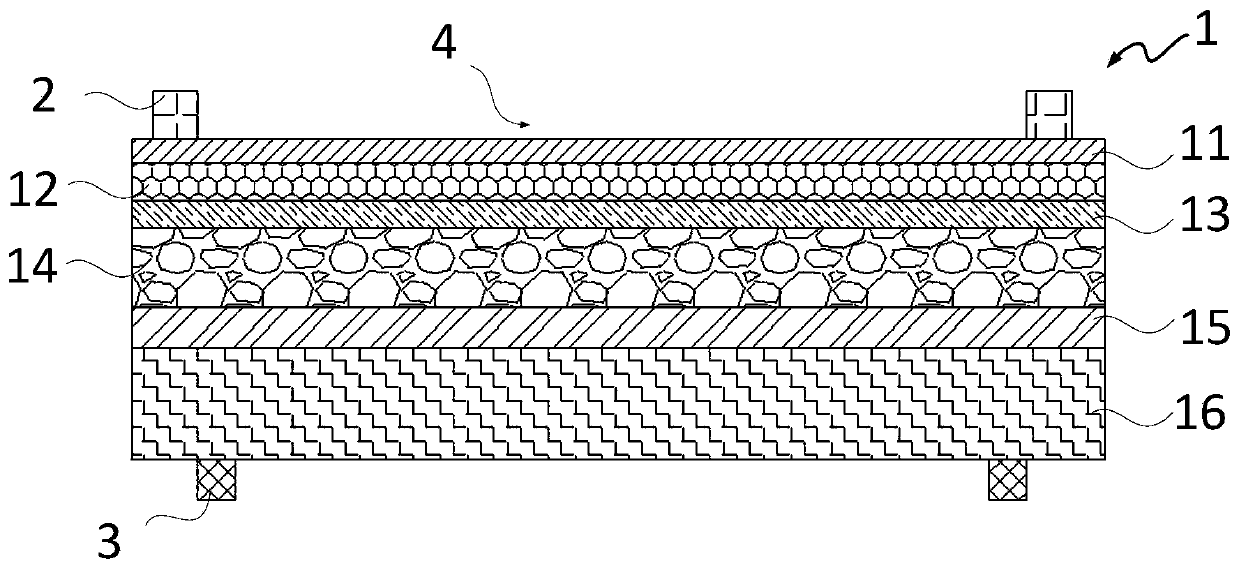

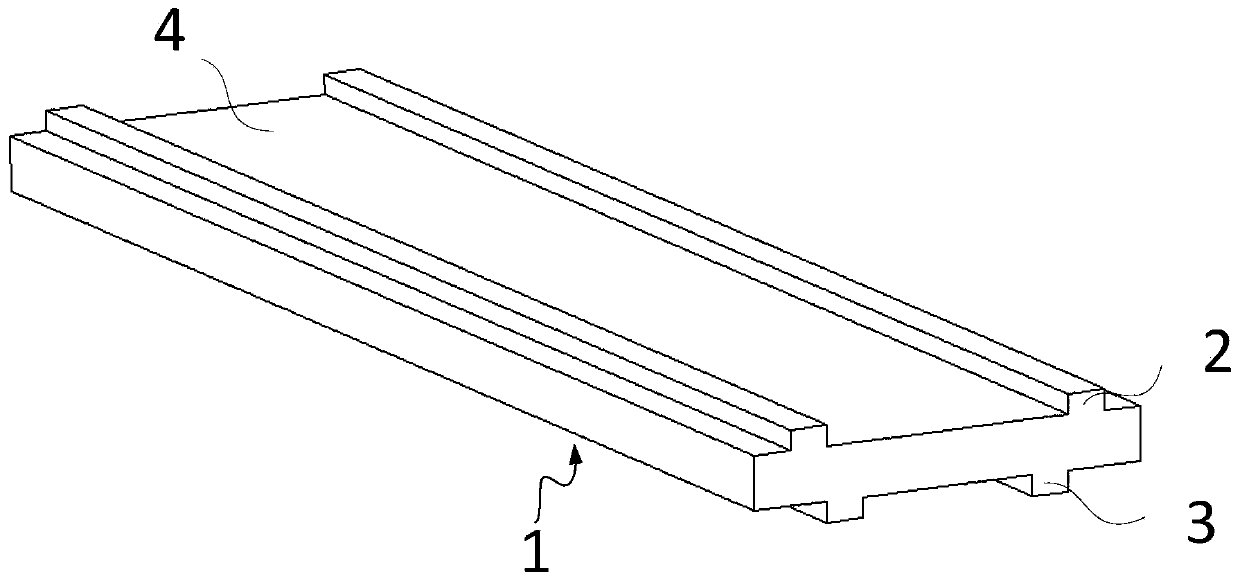

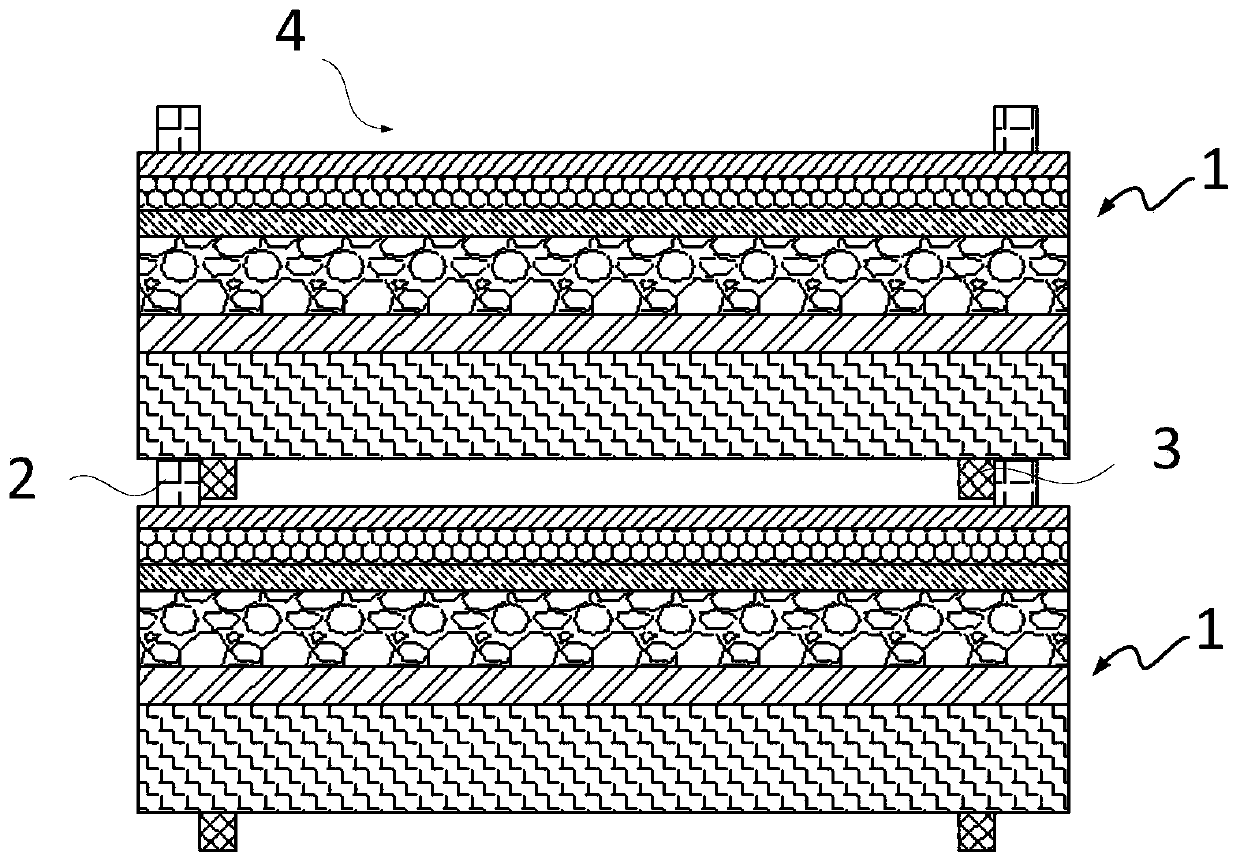

[0042] The present invention provides an aluminum-plastic cover film for blister packaging that is easy to position and cut with the cursor, comprising a cover film body 1, and the cover film body 1 sequentially includes a two-component protective coating 11, an ink layer 12, and a primer layer 13 , aluminum foil layer 14, adhesive layer 15, puncture strength enhancement layer 16, the two-component protective coating 11;

[0043] Wherein, the ink layer 12 includes a cursor pattern;

[0044]The material of the two-component protective coating 11 is polyurethane cross-linking reaction type, including the main agent polyol and curing agent isocyanate prepolymer, the main agent polyol and curing agent isocyanate prepolymer are sequentially mixed, Coating, oven drying, and cross-linking reaction curing form the two-component protective coating 11 , and the temperature of each process is lower than 100° C. to protect the cursor pattern from deformation. After the main agent polyol ...

Embodiment 2

[0055] The invention provides a method for preparing an aluminum-plastic cover film for blister packaging that is easy to position and cut with a cursor, comprising the following steps:

[0056] S1. Unwind the aluminum foil layer 14 with a thickness of 20-30 μm, apply a two-component primer on one side of the aluminum foil layer 14 with a coating thickness of 0.6-1.0 μm, and dry it in an oven at 40°C-80°C for 2-5 seconds, placed at a temperature of 18-22°C for 5 days, a cross-linking reaction occurs, and an undercoat layer 13 is obtained;

[0057] S2. According to the pattern setting requirements, make corresponding gravure rolls, cooperate with the ink to transfer on the primer layer 13, print the pattern on the aluminum foil layer 14 surface coated with the primer layer 13, and dry to get the ink layer 12, ink layer 12 has a thickness of 1-3 μm;

[0058] S3. After mixing the main agent polyol and the curing agent isocyanate prepolymer uniformly in a mass ratio of 100:8-14, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com