A planar mercury cadmium telluride avalanche diode detector and its preparation method

An avalanche diode and mercury cadmium telluride technology, which is applied in the field of infrared detectors, can solve the problems of limiting the effective working bias range and gain range, and achieve the effects of increasing the avalanche breakdown voltage, reducing the electric field strength, and increasing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

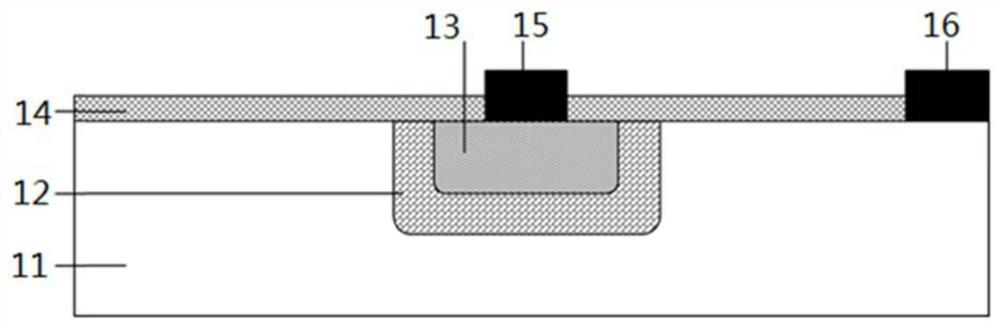

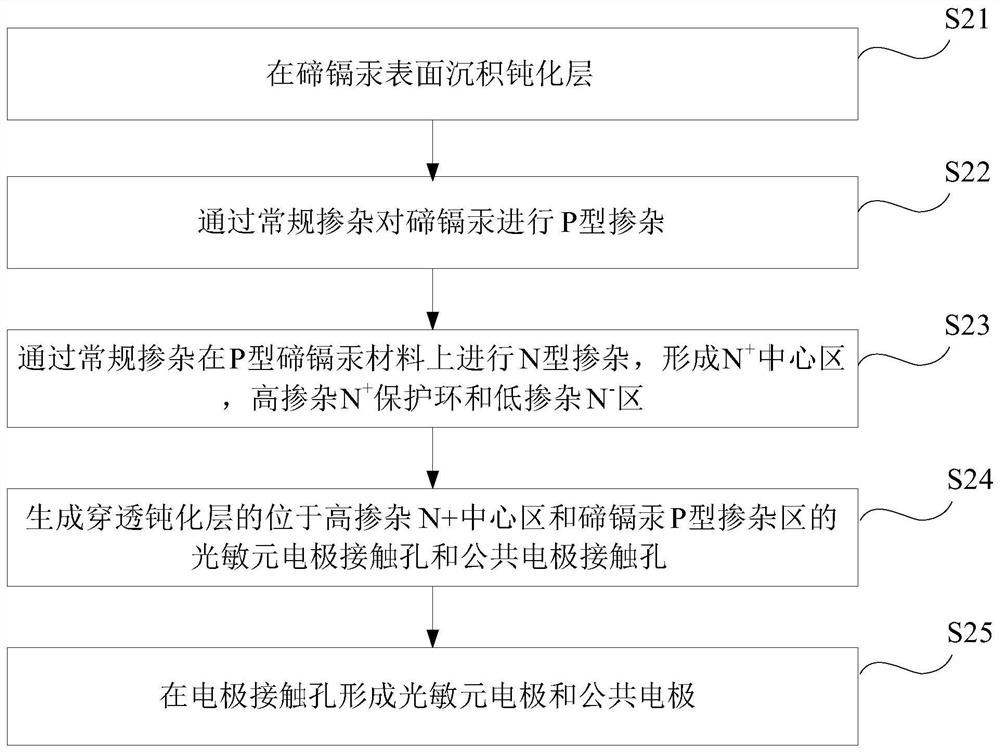

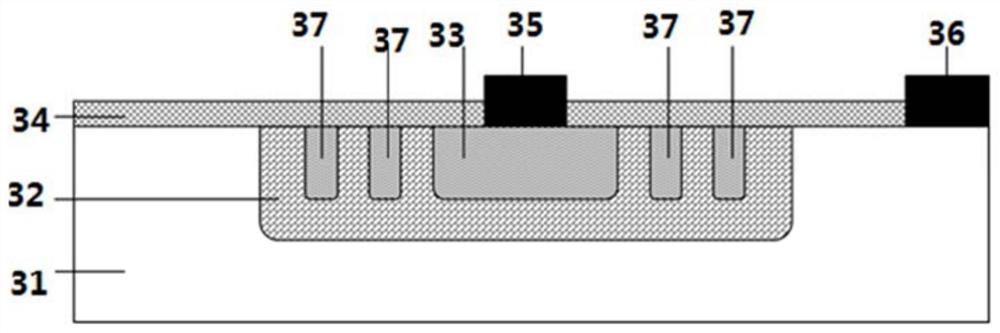

[0035] Such as figure 2 As shown, it is a schematic diagram of the implementation process of the method for preparing a planar mercury cadmium telluride avalanche diode detector provided by the embodiment of the present invention, including the following steps:

[0036] S21. Depositing a passivation layer on the surface of HgCdTe.

[0037] During specific implementation, a passivation layer of cadmium telluride is deposited on the surface of mercury cadmium telluride; or cadmium telluride and zinc sulfide are sequentially deposited on the surface of mercury cadmium telluride to form the passivation layer.

[0038] Wherein, the thickness of the cadmium telluride layer can be 30-500 nm, and the thickness of the zinc sulfide layer can be 0-500 nm.

[0039] S22 , performing P-type doping on HgCdTe by conventional doping.

[0040] Among them, the concentration of HgCdTe P-type doped region can be: 5e15cm -3 ~5e16cm -3 .

[0041] S23. Perform N-type doping on the P-type HgCdTe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com