Biodegradation performance and strength controllable biological composite ceramic bracket and preparation method thereof

A technology of composite ceramics and bioceramics, applied in the direction of additive processing, can solve the problems of difficult forming and degradation of bone scaffolds, and the mechanical properties cannot be well integrated, achieve excellent overall stability and spatial arrangement diversity, improve forming accuracy and Effect of success rate, good mechanical properties and degradation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] (2) Preparation of slurry solvent:

[0047] Mix a variety of photocurable resin monomers or prepolymers in a certain proportion, add plasticizer polyethylene glycol, and then add powder mass (2%-6%)m dispersant, ultrasonic vibration for 1-2 minutes, and then Add photoinitiator, polymerization inhibitor, release agent and lubricant, and stir evenly in a planetary vacuum rotary mixer at a speed of 2000-2900r / min, so that the photoinitiator and polymerization inhibitor are fully mixed to obtain a solvent;

[0048] S2. Preparation of light-cured three-phase ceramic slurry:

[0049] S21. First set the mass as m 1 Add the hydroxyapatite powder into the solvent, put it into a vacuum planetary mixer and stir evenly at a speed of 2000-2900r / min, take it out and add a mass of m 2 The β-tricalcium phosphate powder is stirred evenly at a speed of 2000-2900r / min, and then added with a mass of m 3 The micron-sized biological glass powder is stirred evenly at a speed of 2000-2900r / ...

Embodiment 1

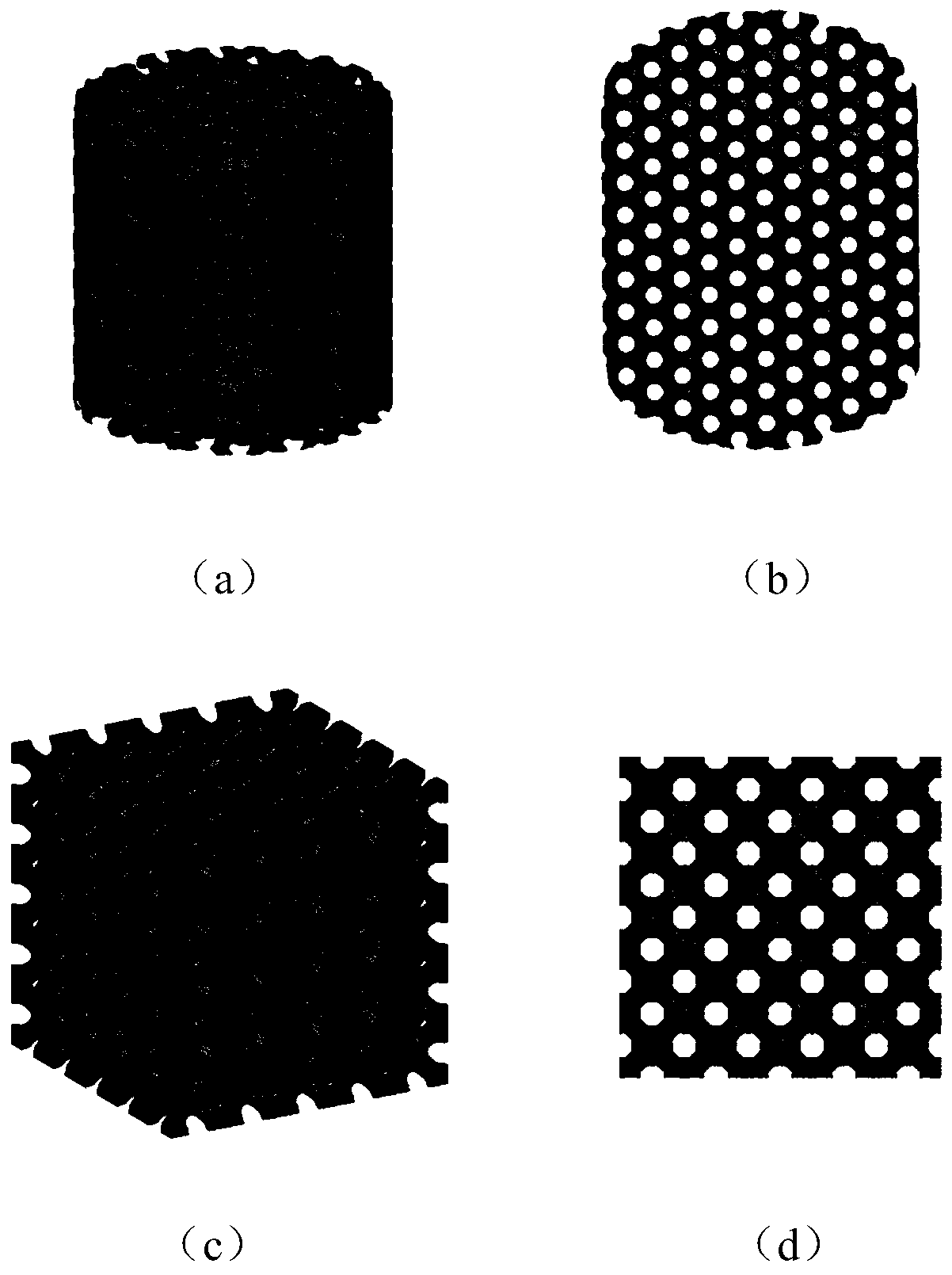

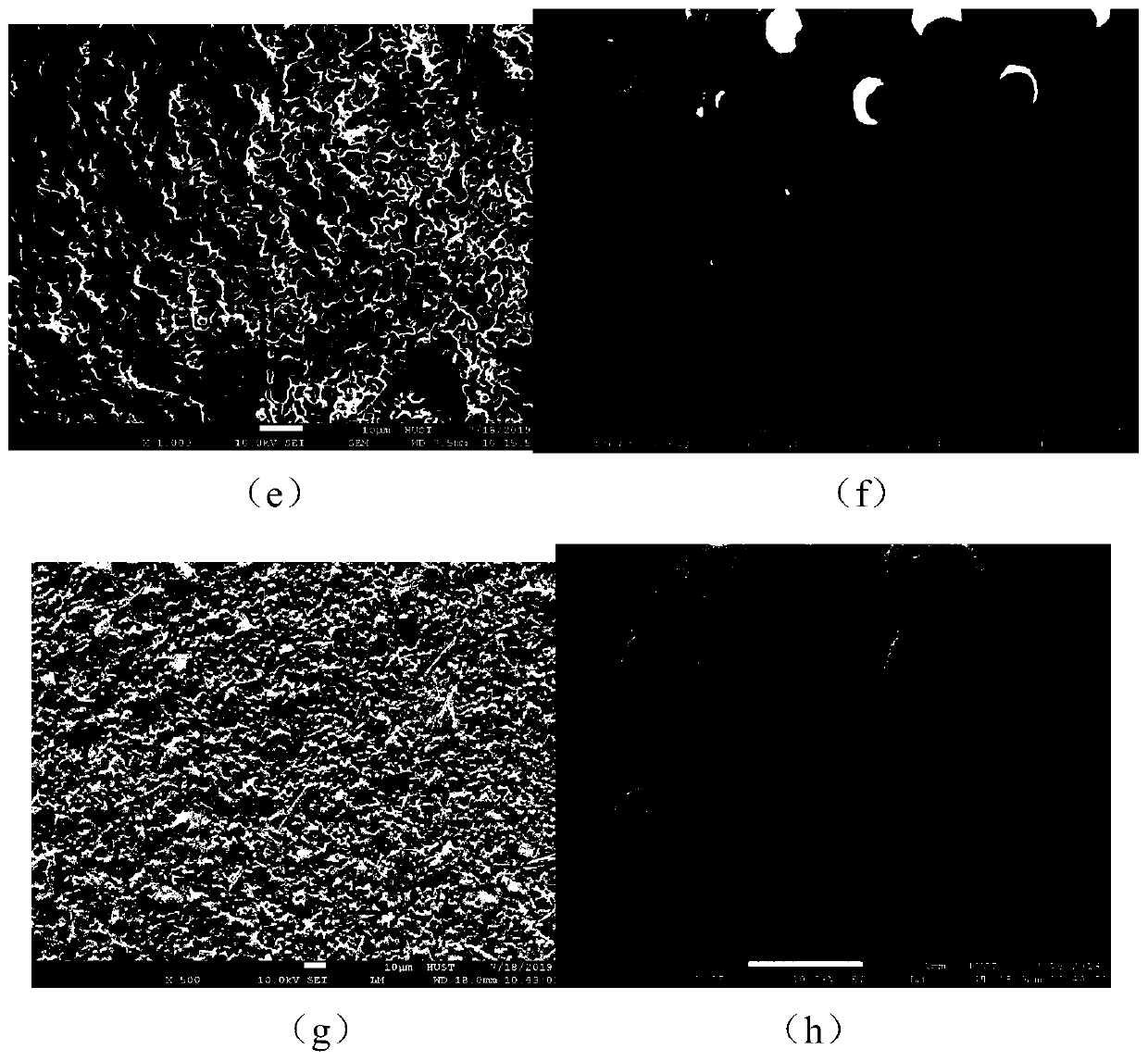

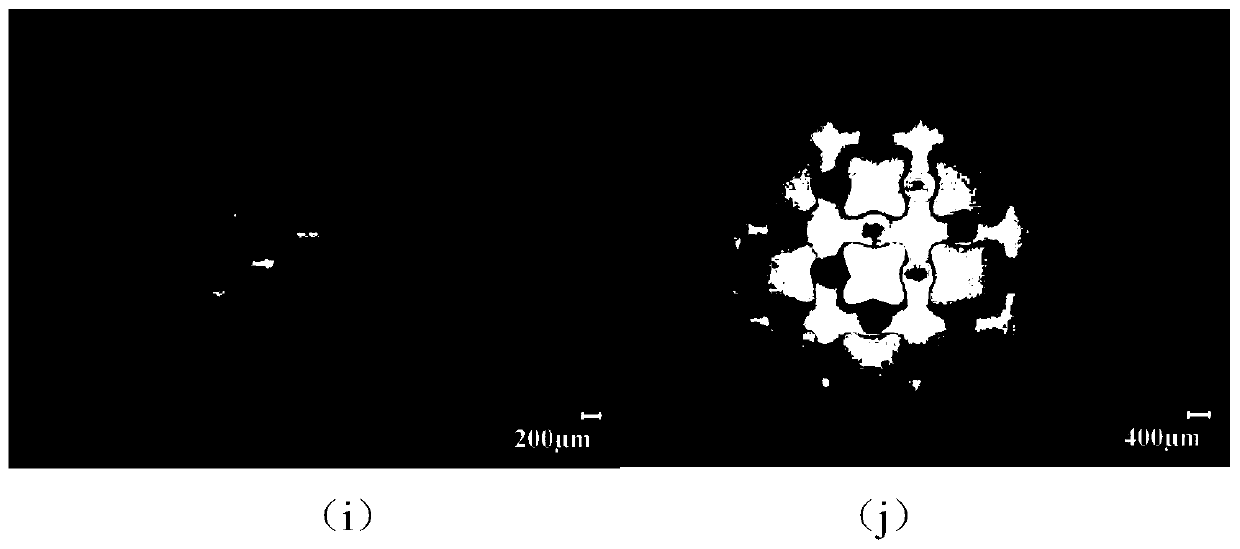

[0073] 1. Use Magics 3D modeling software to design minimal curved surface lattice structures with porosities of 33%, 50%, and 66% through operations such as arrays. Change the hole size between 200-600 µm.

[0074] 2. Put the bio-glass powder in a ball mill with a ball-to-material ratio of 10:1 and mill at 450r / min for 5 hours, take it out and sieve it.

[0075] 3. Prepare bioceramic solvent: weigh 1,6-hexanediol diacrylate (HDDA), tripropylene glycol diacrylate (TPGDA) and polyethylene glycol 200, the total mass is 34.1g, stir with a glass rod Ultrasonic for 1-2 minutes after homogeneity, then add 1% of powder mass release agent rad2500 and 0.5% resin mass of photoinitiator TPO. The polymerization inhibitor p-hydroxyanisole that accounts for 0.1% of resin quality. Place in a planetary vacuum defoaming mixer and stir at 1000r / min for 10s, then at 2900r / min for 10 minutes, and finally at 1000r / min for 10s. Mix the photoinitiator evenly.

[0076] 4. Preparation of biocerami...

Embodiment 2

[0081] 1. Use the K3dsurf software to export the obj format of the minimal surface, put it into the Magics 3D modeling software to thicken it, and convert it into a solid to realize another minimal surface model establishment.

[0082] 2. Same as step 2 in implementation example 1.

[0083] 3. Prepare bioceramic solvent: weigh 1,6-hexanediol diacrylate (HDDA), tripropylene glycol diacrylate (TPGDA) and polyethylene glycol 200, with a total mass of 18g, and stir evenly with a glass rod After ultrasonication for 1-2 minutes, add 1% powder mass release agent rad2500 and 0.5% resin mass photoinitiator TPO. The polymerization inhibitor p-hydroxyanisole that accounts for 0.2% of resin mass. Place in a planetary vacuum defoaming mixer and stir at 1000r / min for 10s, then at 2900r / min for 10 minutes, and finally at 1000r / min for 10s. Mix the photoinitiator evenly.

[0084] 4. Preparation of bioceramic slurry: take by weighing 40g of bioceramic powder total mass, wherein bioglass acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com