Method for preparing perovskite ferroelectric film through non-heat-treatment magnetron sputtering

A ferroelectric thin film, magnetron sputtering technology, applied in sputtering coating, ion implantation coating, metal material coating process and other directions, can solve the problems of complex process and high cost, achieve simple preparation method and wide growth conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

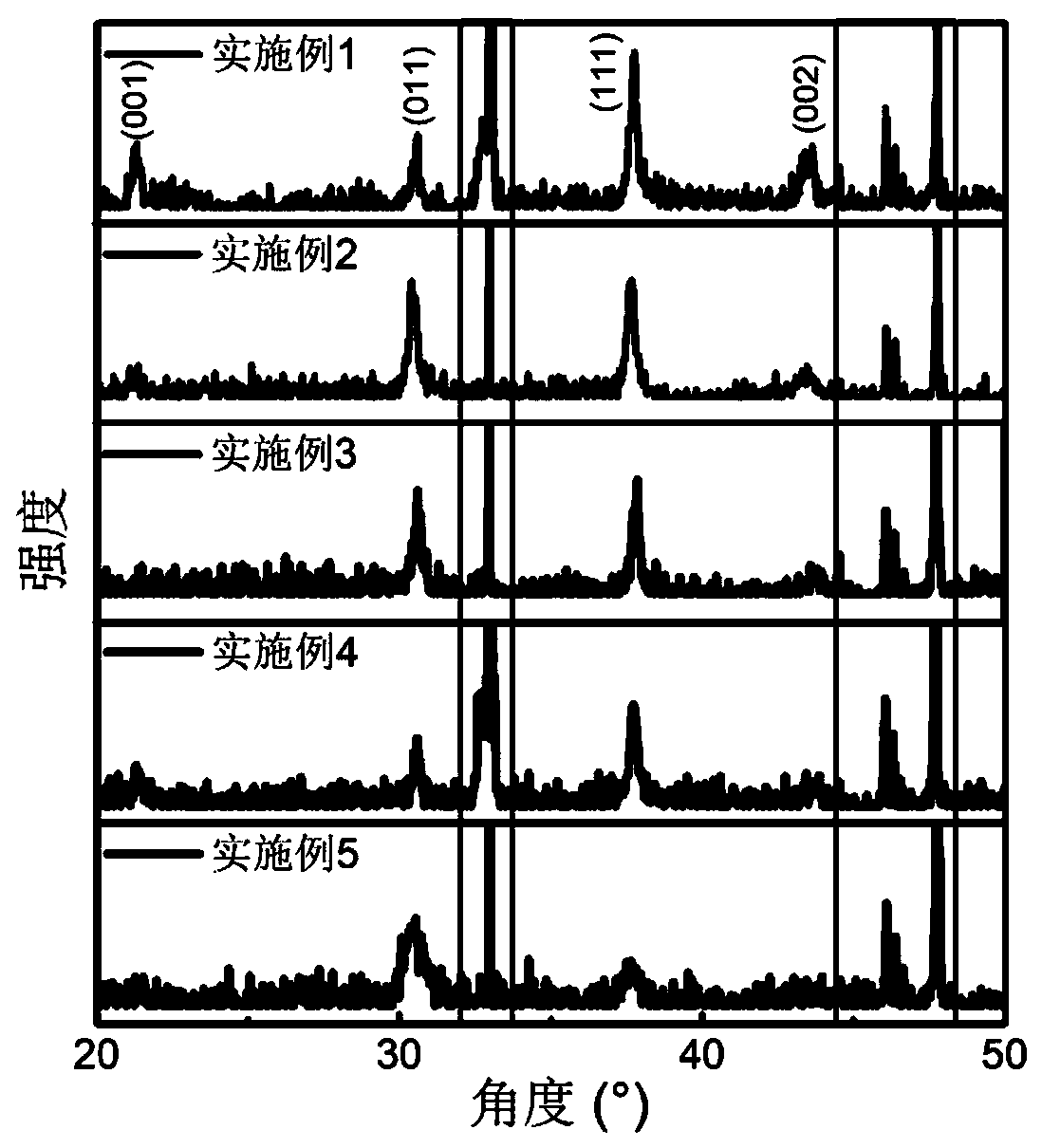

Embodiment 1-5

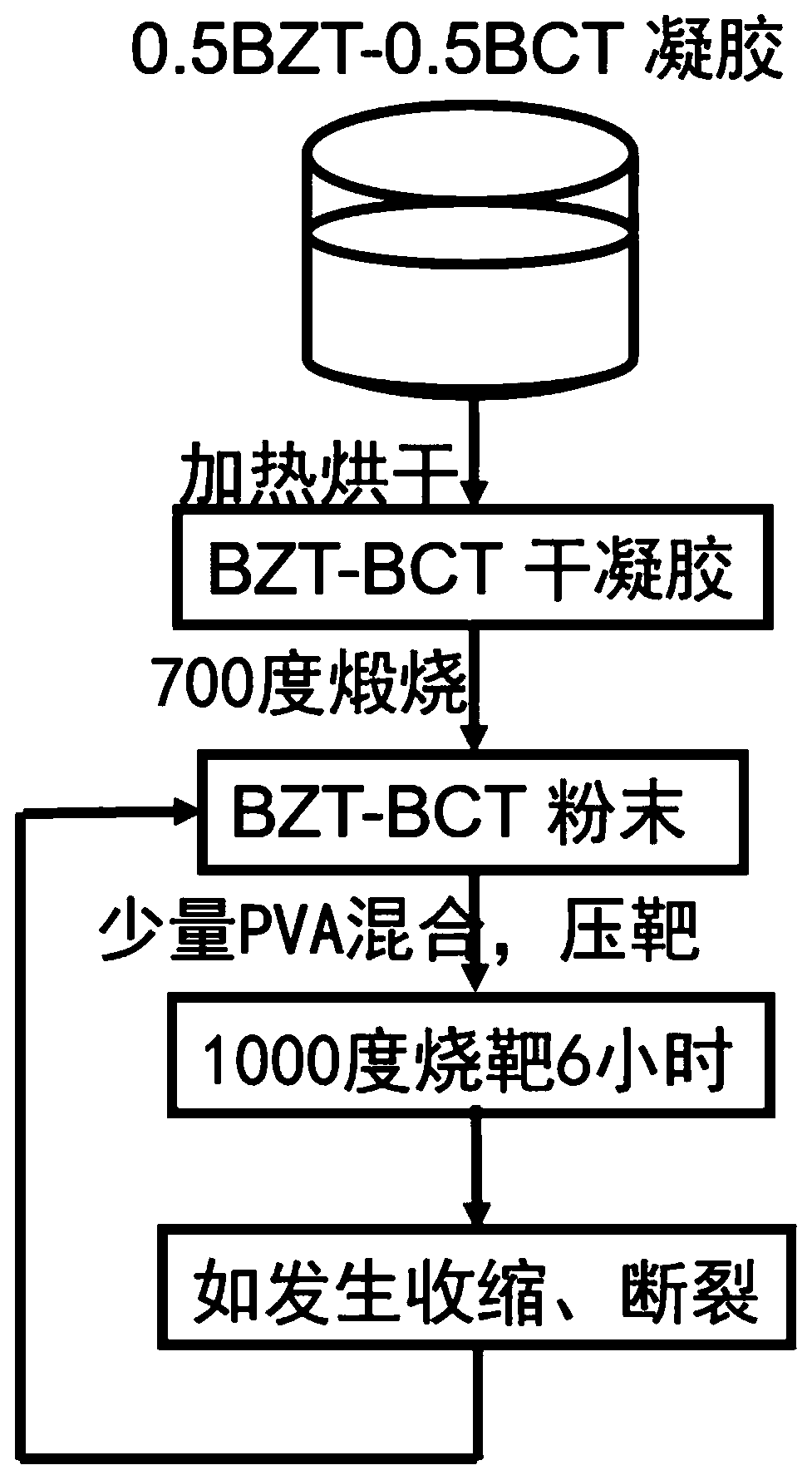

[0026] A method for preparing a perovskite ferroelectric film by magnetron sputtering without heat treatment, the specific steps are as follows:

[0027] (1) Ba(NO 3 ) 2 , Zr(NO 3 ) 4 ·5H 2 O, Ca(NO 3 ) 2 4H 2 O, Ti(OC 4 h 9 ) 4 Prepare BZT-BCT gel as a raw material, then calculate and weigh according to the molar ratio of 17:2:3:18, and weigh the citric acid that is 1.5:1 with the metal cation molar ratio;

[0028] (2) The citric acid in the step (1) is prepared into an aqueous solution with a mass concentration of 20%, then titrated with ammonia water to alkalinity, and then mixed with 10% Ti(OC 4 h 9 ) 4 Alcohol solutions were mixed and stirred for 60 minutes in a water bath at 80°C to obtain a transparent and clear solution;

[0029] (3) Zr(NO 3 ) 4 ·5H 2 O, Ca(NO 3 ) 2 4H 2 O and Ba(NO 3 ) 2 Mix and prepare an inorganic salt solution with a mass concentration of 5%.

[0030] (4) Evenly mix the clear solution in step (2) with the inorganic salt soluti...

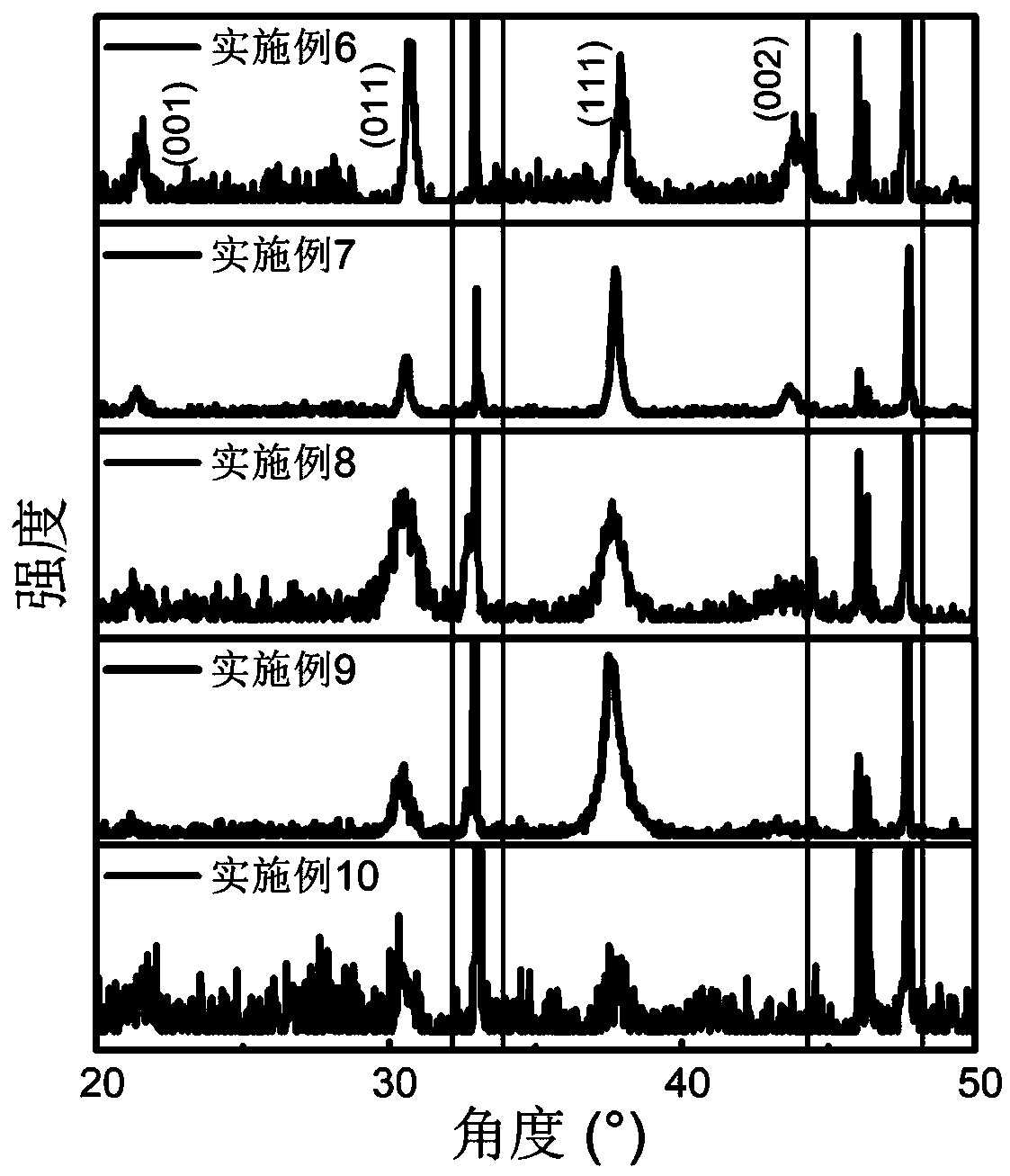

Embodiment 6-10

[0036] A method for preparing a perovskite ferroelectric film by magnetron sputtering without heat treatment, the specific steps are as follows:

[0037] (1) Ba(NO 3 ) 2 , Zr(NO 3 ) 4 ·5H 2 O, Ca(NO 3 ) 2 4H 2 O, Ti(OC 4 h 9 ) 4 Prepare BZT-BCT gel as a raw material, then calculate and weigh according to the molar ratio of 17:2:3:18, and weigh the citric acid that is 1.5:1 with the metal cation molar ratio;

[0038] (2) The citric acid in the step (1) is prepared into an aqueous solution with a mass concentration of 20%, then titrated with ammonia water to alkalinity, and then mixed with 10% Ti(OC 4 h 9 ) 4 Alcohol solutions were mixed and stirred for 60 minutes in a water bath at 80°C to obtain a transparent and clear solution;

[0039] (3) Zr(NO 3 ) 4 ·5H 2 O, Ca(NO 3 ) 2 4H 2 O and Ba(NO 3 )2 Mix and prepare an inorganic salt solution with a mass concentration of 5%.

[0040] (4) Evenly mix the clear solution in step (2) with the inorganic salt solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com