Quantum dot composite brightening film and preparation method thereof

A technology of quantum dot film and brightness enhancement film, which is applied in the field of quantum dot composite brightness enhancement film and its preparation, can solve the problems that it is difficult to ensure that the film does not deform, reduce production yield, and increase process defects, so as to reduce process defects , reduce installation time, reduce performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In order to solve the above-mentioned technical problems of cumbersome quantum dot film preparation process, poor manufacturing process and low production yield, the present invention also discloses a method for preparing a quantum dot composite brightness enhancement film with simple operation and simple process, which specifically includes the following steps :

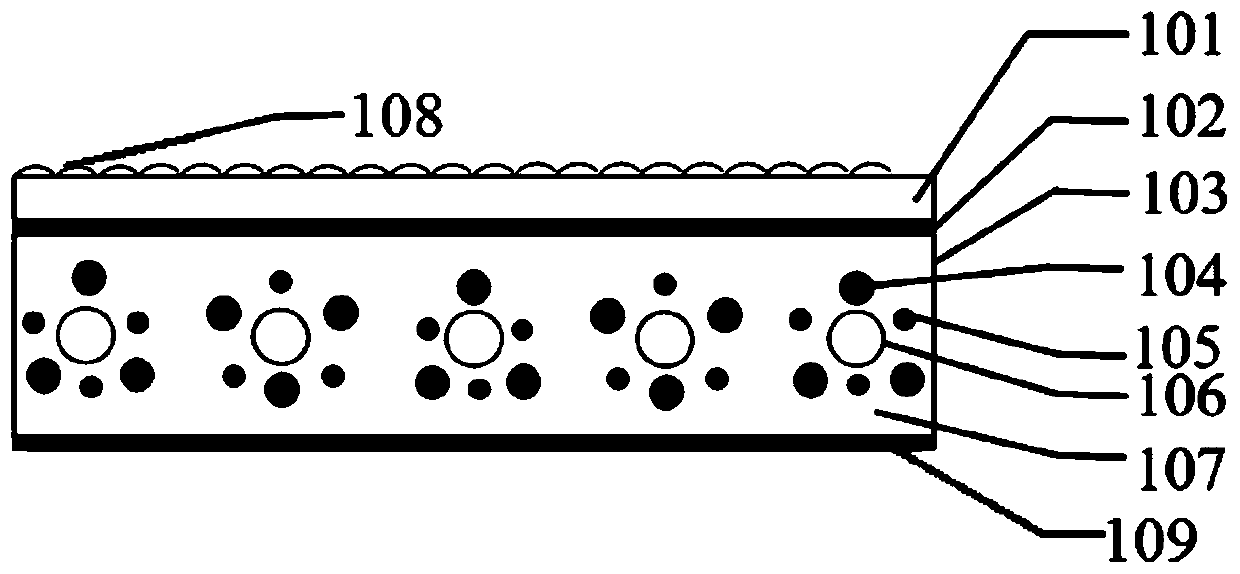

[0041] (1) The quantum dots are dissolved in the quantum dot stabilizer to obtain the quantum dot solution; after the quantum dot solution is mixed with the matrix resin 107, the scattering particles 106, the initiator and the diluent, it is coated by a slit and attached to the side of the upper layer respectively. The first barrier layer 102 with the substrate layer 101 and the second barrier layer 109 of the lower layer are bonded together, and under the action of light and heat, the intermediate quantum dot layer 103 is cured to form a quantum dot film layer; (2) using The ultraviolet light curing adhesive...

Embodiment 1

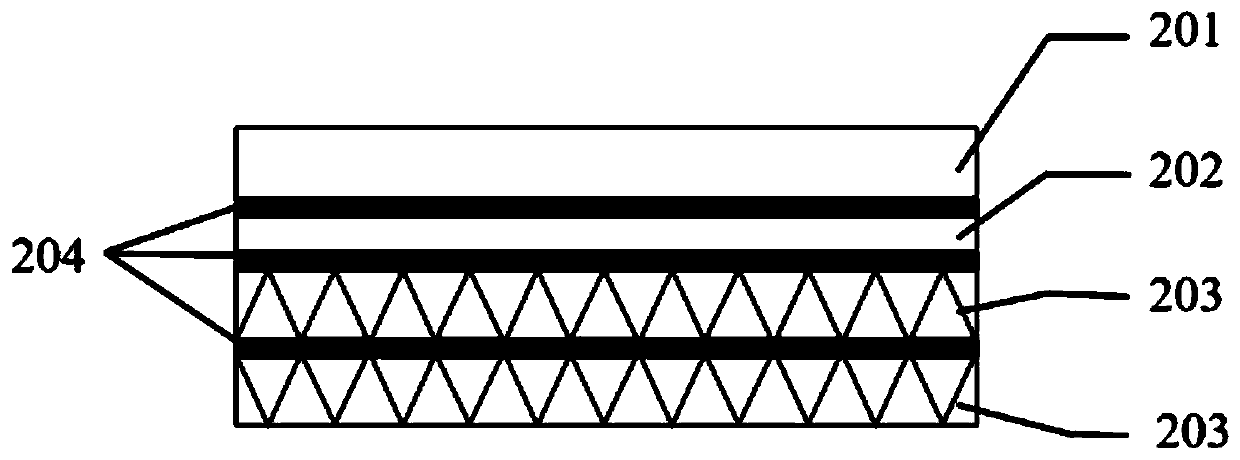

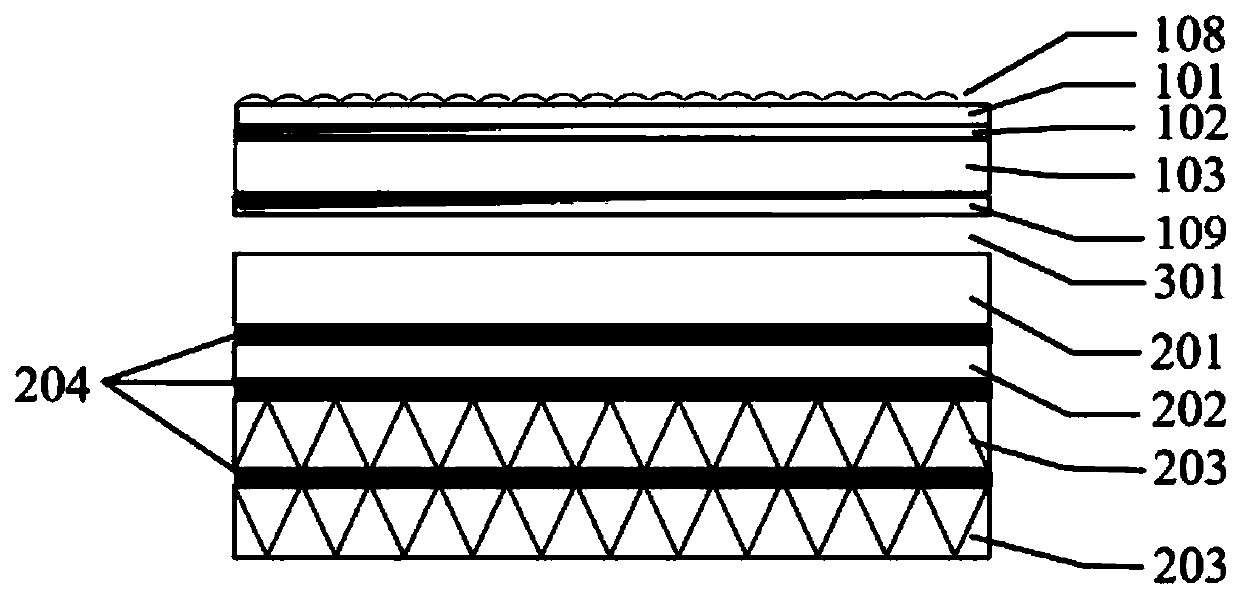

[0044] First prepare the quantum dot film layer: the quantum dots are dissolved in the quantum dot stabilizer to obtain a quantum dot solution. After the quantum dot solution is mixed with the matrix resin 107, the scattering particles 106, the initiator and the diluent, it is coated with the upper layer through a slit. The PET layer with the first barrier layer 102 is bonded to the lower second barrier layer 109, and under the action of light and heat, the intermediate quantum dot layer 103 is cured to form a quantum dot film layer, which can then be rolled into a roll material; secondly prepare the composite brightening film layer: the diffusion layer 201, the core layer 202, and the prism layer 203 are cured and bonded by ultraviolet curing glue (UV glue). The composite brightness enhancement film can be rolled into a roll later. In this embodiment, the composite brightness enhancement film is provided with only one layer of prism layer 203; finally, the second barrier layer...

Embodiment 2

[0046] The difference between Example 2 and Example 1 is that the prepared composite brightness-enhancing film layer is provided with two prism layers 203 on the side of the core layer 202 away from the diffusion layer 201, and the two prism layers 203 are cured and pasted with UV glue, quantum The other preparation processes of the dot composite brightness enhancement film remain unchanged.

[0047] Wherein, compared with embodiment 1, in embodiment 2, the brightness of the quantum dot composite brightness enhancing film is increased by 5.3% after adding a prism layer.

[0048] Table 1 Performance comparison table of quantum dot composite brightness enhancement film

[0049] Example point of difference Brightness (cd / m 2 )

[0050] The quantum dot composite brightness-enhancing film disclosed by the present invention sets the quantum dot composite brightness-enhancing film into a multi-layer structure, and does not need to coat the quantum dot film layer multi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com