Preparation method of ultra-small-size iron oxide nanoparticles and application thereof

A technology of iron oxide nanometers and iron oxide particles, which is applied in the field of cell tracers, can solve the problems of increasing particle size and weakening the positive enhancement performance of ultra-small iron oxide, and achieves simple preparation methods, solving the problem of strong magnetic susceptibility, The effect of improving intake efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

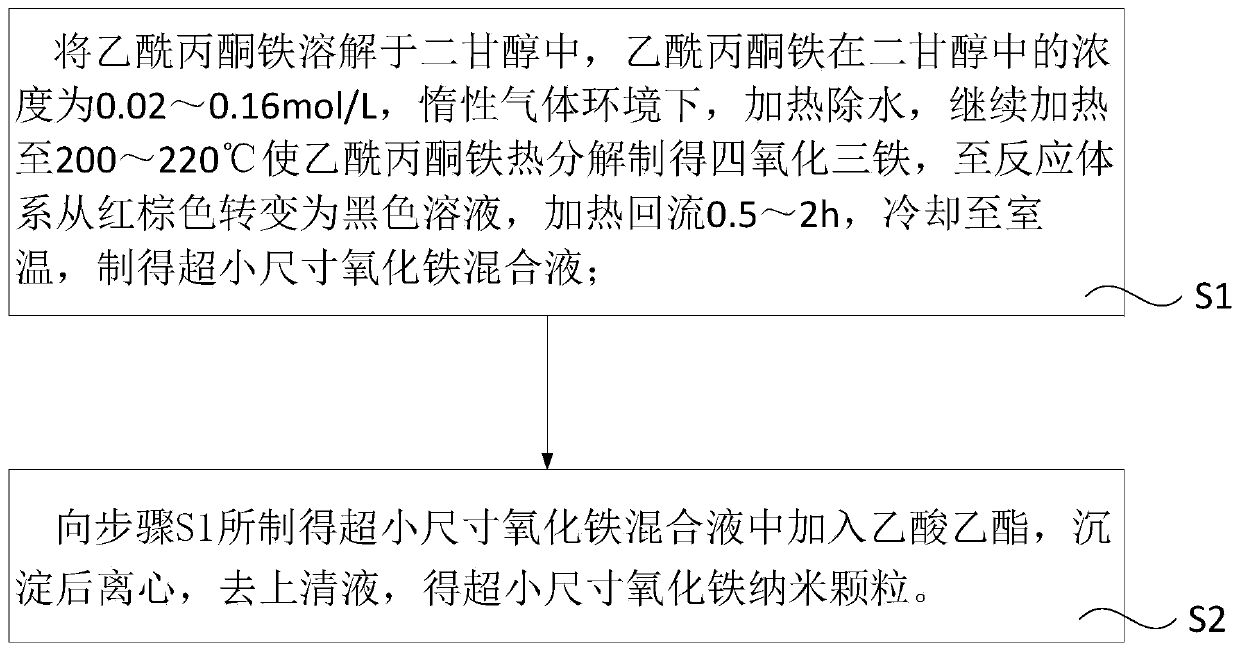

[0038] Preparation of Ultra-Small Size Iron Oxide Particles

[0039] S1. Mix 1mmol of iron acetylacetonate and 25ml of diethylene glycol and add them into a three-neck round bottom flask, wherein the concentration of iron acetylacetonate in diethylene glycol is 0.04mol / L, and feed argon for 15min; then Heat at a rate of 3°C / min to 120°C, keep warm for 1 hour to remove water; then heat at a rate of 3°C / min to 200°C, the reaction system gradually turns from reddish brown to a black solution, heat to reflux for 0.5h, and cool naturally to room temperature. Prepare ultra-small iron oxide mixed liquid;

[0040] S2. Add ethyl acetate to the super-small iron oxide mixture prepared in step S1 after cooling to precipitate the iron oxide nanoparticles, then centrifuge at 8000rpm for 20min, remove the supernatant; then disperse the precipitate in ethanol , and then precipitated with ethyl acetate and centrifuged three times to obtain ultra-small iron oxide nanoparticles;

[0041] S3. T...

Embodiment 2

[0043] Preparation of Ultra-Small Size Iron Oxide Particles

[0044] S1. Mix 20mmol of iron acetylacetonate and 1000ml of diethylene glycol and add them into a three-neck round bottom flask, wherein the concentration of iron acetylacetonate in diethylene glycol is 0.02mol / L, and feed argon for 25min; then Heating at a rate of 4 °C / min to 130 °C, keeping it warm for 1.5 hours to remove water; then heating at a rate of 7 °C / min to 210 °C, the reaction system gradually turns from reddish brown to a black solution, heated to reflux for 1 hour, and cooled naturally to room temperature. Prepare ultra-small iron oxide mixed liquid;

[0045] S2. Add ethyl acetate to the super-small iron oxide mixture prepared in step S1 after cooling to precipitate the iron oxide nanoparticles, then centrifuge at 8000rpm for 20min, remove the supernatant; then disperse the precipitate in ethanol , and then precipitated with ethyl acetate and centrifuged three times to obtain ultra-small iron oxide na...

Embodiment 3

[0048] Preparation of Ultra-Small Size Iron Oxide Particles

[0049] S1. Mix 32mmol of iron acetylacetonate and 200ml of diethylene glycol and add them into a three-neck round bottom flask, wherein the concentration of iron acetylacetonate in diethylene glycol is 0.16mol / L, and feed argon for 25min; then Heating at a rate of 5 °C / min to 100 °C, keeping it warm for 2 hours to remove water; then heating at a rate of 10 °C / min to 220 °C, the reaction system gradually changed from reddish brown to a black solution, heated to reflux for 2 hours, and naturally cooled to room temperature to prepare Obtain ultra-small size iron oxide mixture;

[0050] S2. Add ethyl acetate to the super-small iron oxide mixture prepared in step S1 after cooling to precipitate the iron oxide nanoparticles, then centrifuge at 8000rpm for 20min, remove the supernatant; then disperse the precipitate in ethanol , and then precipitated with ethyl acetate and centrifuged three times to obtain ultra-small iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com