Method for preparing multilayer spiral urethral tissue engineering scaffold

A tissue engineering stent and urethra technology, which is applied in the field of preparation of tissue engineering urethral stents for urethral diseases, can solve the problems of hindering the physiological activity of the urethra, sudden disintegration, slow expansion rate, etc., and achieves the effect of reducing surface coverage and avoiding urethral blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

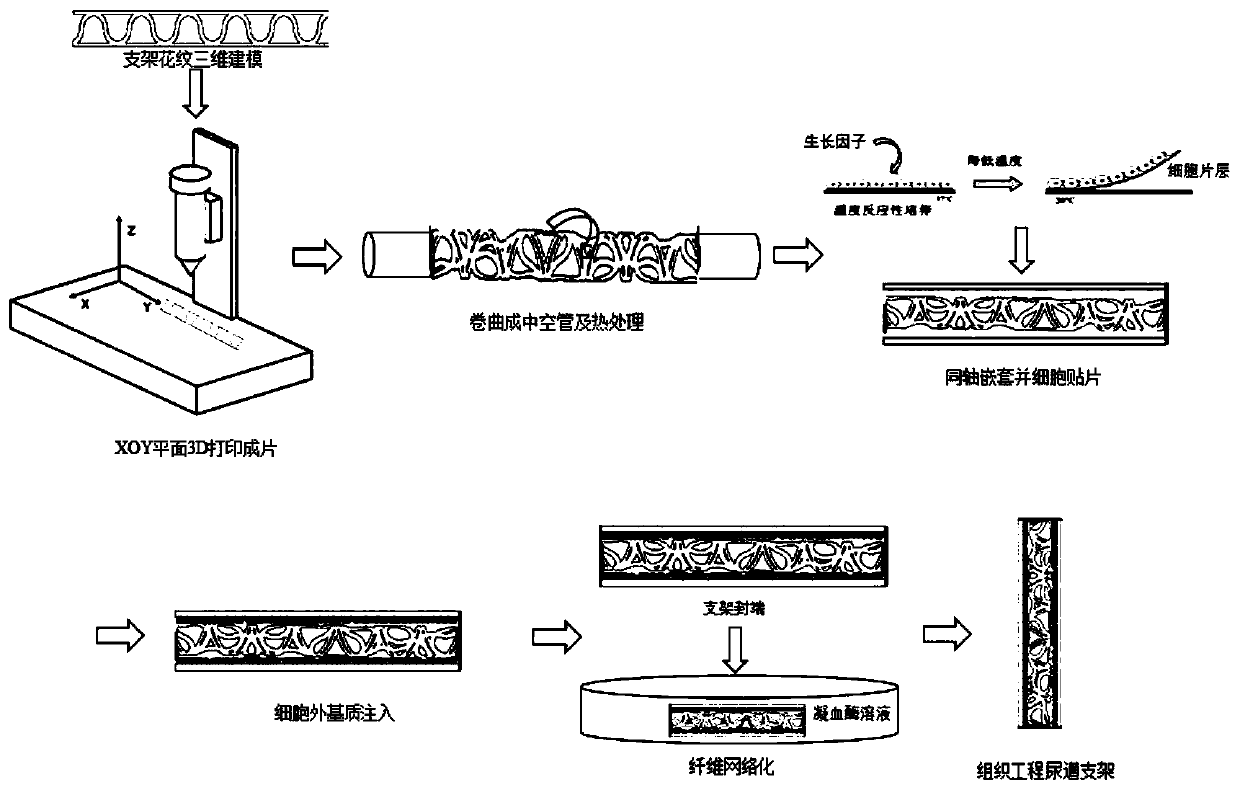

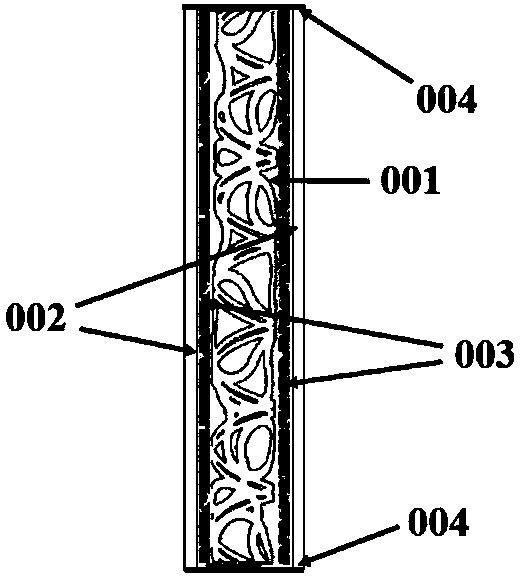

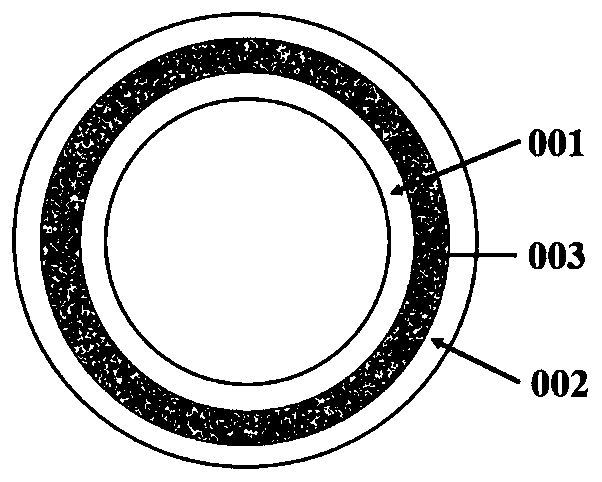

[0043] A kind of preparation of urethra tissue engineering support, comprises the steps:

[0044] (1) Using polylactic acid-glycolic acid (PLGA) copolymer as raw material (LA:GA=75:25, Mv=100000), after three-dimensional modeling, import the .stl file into the fused deposition 3D printer and print out two surfaces A rectangular long embryo body with a coverage rate of 20% and a spline curve pattern; the wall thickness of the support, that is, the thickness of the rectangular long embryo body is 0.1 mm; 1 3.0mm and φ 2 On a 5.6mm mold; both ends are fixed with thin copper wires; then placed in a vacuum oven at 120 ° C for 10 minutes to promote polymer crystallization and the shape of the bracket; after cooling, take out the mold to obtain monolayers with different diameters The bracket is then cut into a long tube with a length of 30.0mm.

[0045] (2) The stents of equal length and matching diameter are coaxially nested and fixed to form a double-layer stent, and one end of t...

Embodiment 2

[0054] A kind of preparation of urethra tissue engineering support, comprises the steps:

[0055] (1) Using polylactic acid (molecular weight: 100,000) as the raw material, import the .stl file into the fused deposition 3D printer after 3D modeling and print out two rectangular strips with a surface coverage of 30% and spline curve patterns Body, the wall thickness of the stent, that is, the thickness of the rectangular long strip embryo body is 0.3mm; respectively, two rectangular long strip embryo bodies are helically crimped with diameters of φ 1 = 4.0mm and φ 2 = 6.8mm on the mold; both ends are respectively fixed with thin copper wires; then placed in a vacuum oven at 90°C for 10 minutes to be annealed and shaped; after the mold is cooled, the mold is taken out to obtain single-layer stents of different diameters, which are all cut to length A long tube of 40.0mm.

[0056] (2) A double-layered stent is formed by coaxially nesting and fixing stents of equal length and ma...

Embodiment 3

[0065] A kind of preparation of urethra tissue engineering support, comprises the steps:

[0066] (1) Using polycaprolactone (molecular weight: 50,000) as the raw material, import the .st1 file into the fused deposition 3D printer after three-dimensional modeling and print out two rectangles with a surface coverage of 40% and spline curve patterns. Strip-shaped embryo body, the wall thickness of the support, that is, the thickness of the rectangular long strip embryo body is 0.4mm; two rectangular long strip embryo bodies are helically crimped on diameters of φ 1 = 4.5mm and φ 2 = 7.3mm on the mold; both ends are respectively fixed with thin copper wires; then placed in a vacuum oven at 30°C for annealing for 20 minutes and finalized; after the mold is cooled, take out the mold to obtain single-layer stents with different diameters, and cut them into lengths A long tube of 60.0mm.

[0067](2) The stents of equal length and matching diameter are coaxially nested and fixed to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com