Modified triethylene glycol composition and its device for dehumidifying low-concentration gas

A technology of triethylene glycol and composition, applied in the field of gas treatment, can solve problems such as corrosion of equipment, generation of acidic substances, darkening of color, etc., and achieve the effects of small pressure loss, inhibition of oxidation, and good dehumidification function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Low Concentration Gas Dehumidification Test

[0050] Dialkyl diphenylamine (stabilizer), polyanisole (viscosity reducer), and triethylene glycol were mixed at a mass ratio of 1:0.1:98.9 to obtain 1.5 kg of the modified triethylene glycol composition of this example.

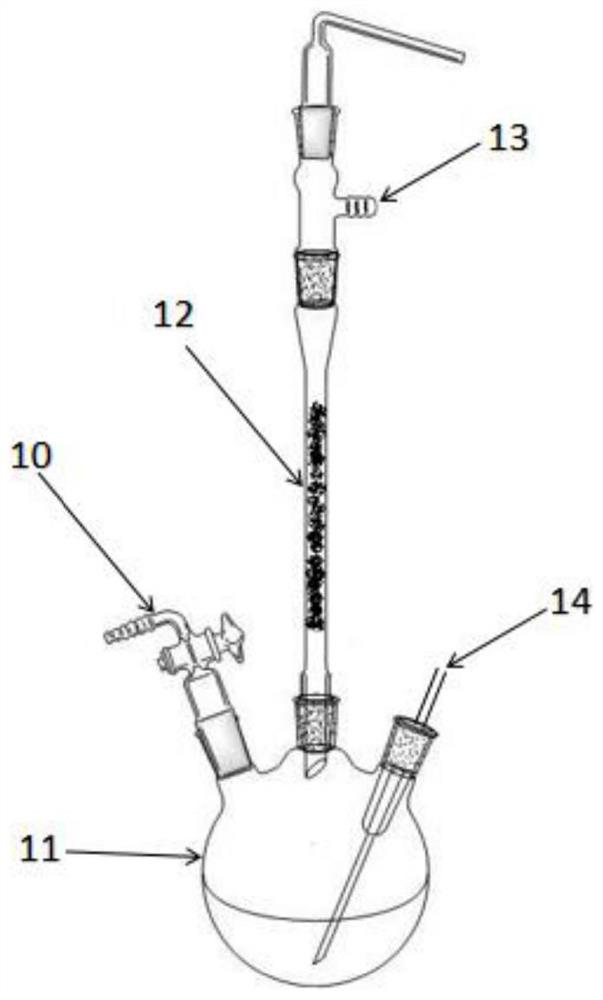

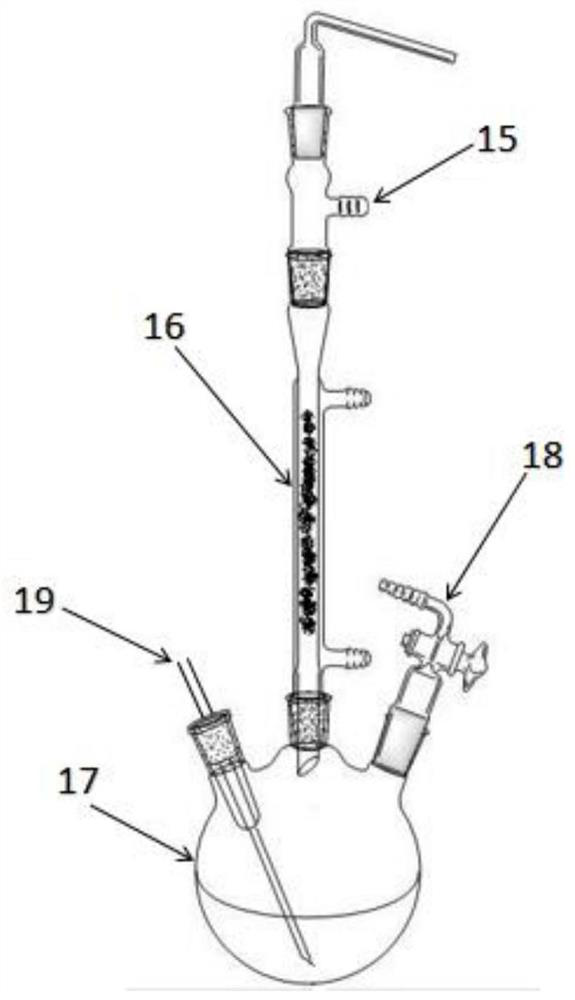

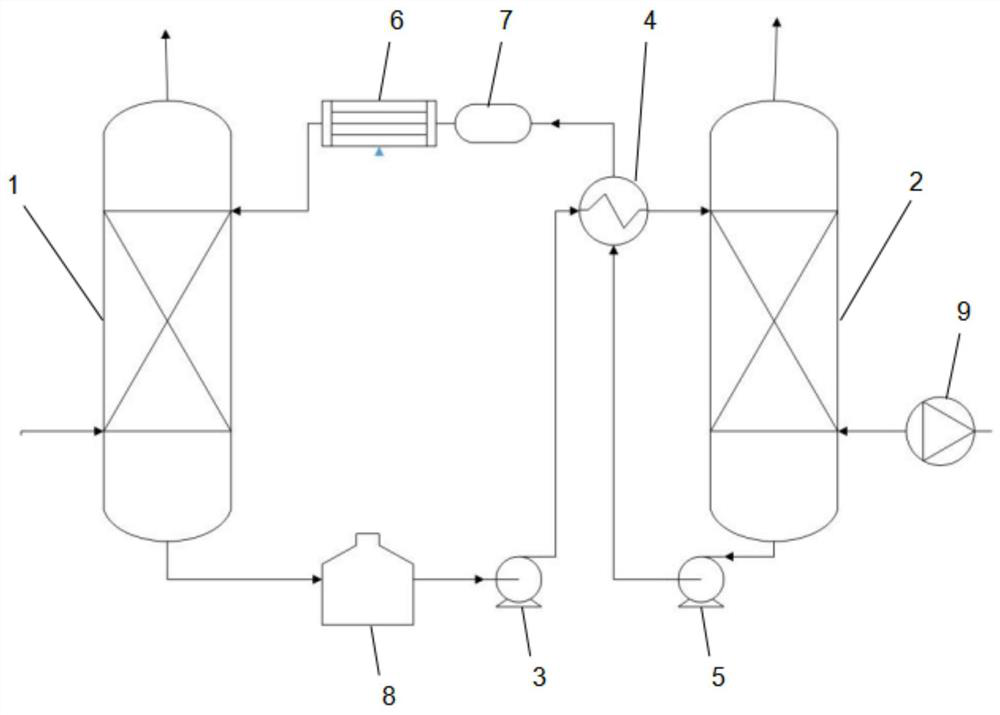

[0051] The modified triethylene glycol composition of the present embodiment is carried out the low-concentration gas dehumidification test, and the specific test method is as follows (in the following tests, the modified triethylene glycol composition of the present embodiment is referred to as modified triethylene glycol for short. ):Such as figure 1 with figure 2 Shown, relative humidity (25 ℃) is 100%, gauge pressure is that 10kPa low-concentration gas (methane content 30%) enters in No. 1 three-necked flask 11 with the flow rate of 3L / min through first piston joint 10, then upwards passes through The first rectifying column 12 (inside diameter is 2cm, is filled with 10cm high Raschig ring...

Embodiment 2

[0059] Mix hydroquinone (stabilizer), nonylphenol polyoxyethylene ether (viscosity reducer), and triethylene glycol at a mass ratio of 0.1:2:97.9 to obtain the modified triethylene glycol composition 1.5 of this embodiment. kg.

[0060] The low-concentration gas dehumidification test was carried out on the modified triethylene glycol composition of this example in the same manner as in Example 1. When the test was carried out for 5 days, 10 days, 15 days and 30 days, the low-concentration gas passed through the modified triethylene glycol. The relative humidity after alcohol dehumidification, the measurement results are shown in Table 3.

[0061] Table 3 Relative humidity of low-concentration gas after dehumidification by modified triethylene glycol in Example 2

[0062]

[0063] Observe the properties of the modified triethylene glycol composition after 30 minutes, 5 days, 10 days, 15 days and 30 days after dehumidification of low-concentration gas and detect its pH. The ...

Embodiment 3

[0067] Antioxidant 330 (stabilizer), antioxidant 1076 (stabilizer), polyethylene glycol (viscosity reducer), cyclohexylamine nitrite (passivator), polyoxypropylene oxide ethylene glyceryl ether (defoaming agent) agent), triethylene glycol were mixed at a mass ratio of 0.2:0.3:0.5:0.5:0.001:98.499 to obtain 1.5 kg of the modified triethylene glycol composition of this embodiment.

[0068] The low-concentration gas dehumidification test was carried out on the modified triethylene glycol composition of this example in the same manner as in Example 1. When the test was carried out for 5 days, 10 days, 15 days and 30 days, the low-concentration gas passed through the modified triethylene glycol. The relative humidity after alcohol dehumidification, the measurement results are shown in Table 5.

[0069] Table 5 Relative humidity of low-concentration gas after dehumidification by modified triethylene glycol in Example 3

[0070]

[0071] Observe the properties of the modified tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com