Method for preparing high strength and ductility magnesium-rare earth alloy through selective laser melting additive manufacturing technology

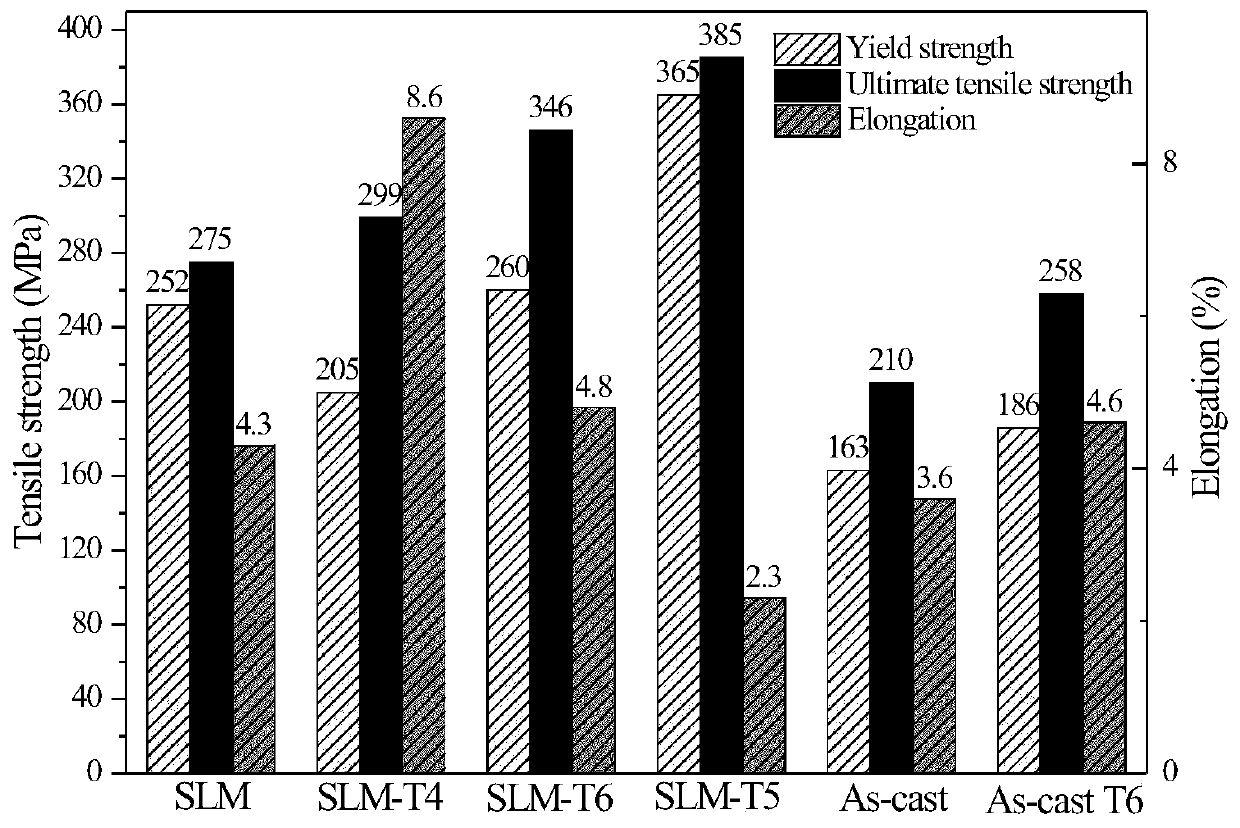

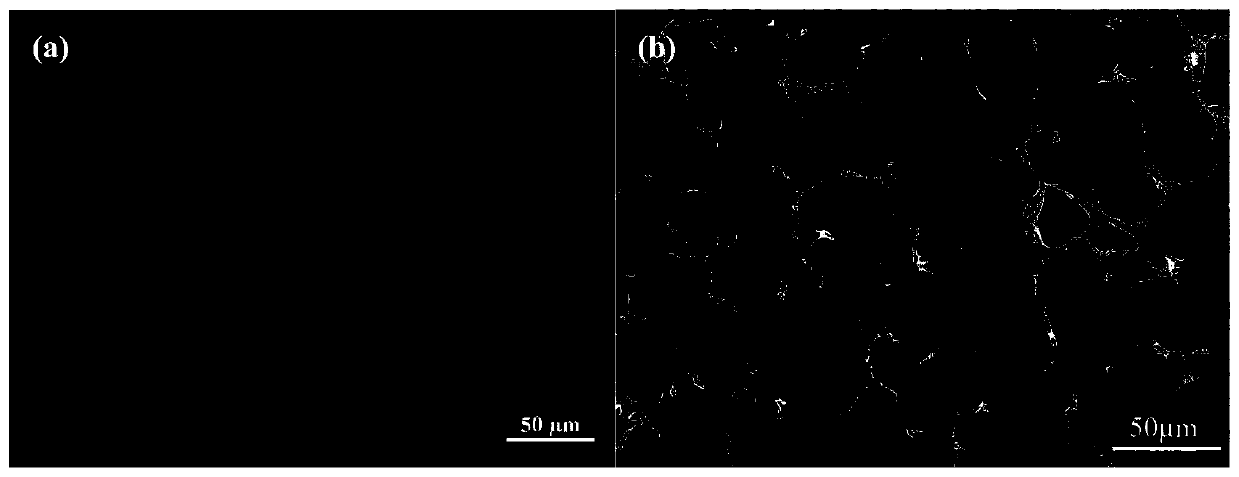

A technology of selective laser melting and magnesium-rare-earth alloys, which is applied in the direction of additive manufacturing, additive processing, and energy efficiency improvement. It can solve the problems of grain and eutectic phase coarseness, inclusion mechanical properties, composition segregation, etc. Low phase content, good product stability, and improved structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a method for preparing a high-strength and tough magnesium rare-earth alloy by selective laser melting additive manufacturing technology, and specifically adopts the following steps:

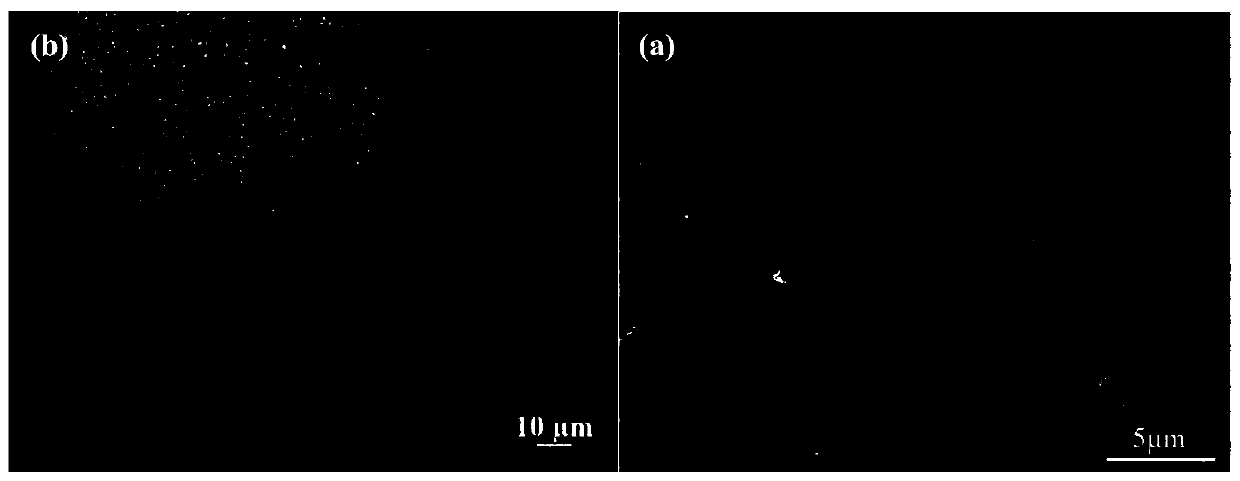

[0041] 1) Prepare Mg-11.16Gd-1.72Zn-0.44Zr (wt.%) alloy powder by gas atomization method, and sieve the alloy powder, select 300-500 mesh (average particle size: 42μm) powder Perform selective laser melting.

[0042] 2) Dry the powder in a vacuum drying oven at 200°C / 5h, then put it into the powder bed of the selective laser melting equipment, and preheat the substrate to 200°C, pass in the protective gas argon for gas circulation, and wait for the molding chamber Indoor oxygen and water vapor content is lower than 100ppm to start selective laser melting molding.

[0043] 3) The laser power used in the selective laser melting molding is 80W, the scanning speed is 500mm / s, the scanning distance is 100μm, the spot diameter is 100μm, the layer thickness is 30μm, the...

Embodiment 2

[0050] This embodiment provides a method for preparing a high-strength and tough magnesium rare-earth alloy by selective laser melting additive manufacturing technology, and specifically adopts the following steps:

[0051] 1) Prepare Mg-14.92Gd-0.30Zr (wt.%) alloy powder by gas atomization method, and sieve the alloy powder, select 300-500 mesh (average particle size: 42μm) powder for selective laser Melt molding.

[0052] 2) Dry the powder in a vacuum drying oven at 200°C / 5h, then put it into the powder bed of the selective laser melting equipment, and preheat the substrate to 150°C, pass in the protective gas argon for gas circulation, and wait for the molding chamber Indoor oxygen and water vapor content is lower than 100ppm to start selective laser melting molding.

[0053] 3) The laser power used in the selective laser melting molding is 80W, the scanning speed is 100mm / s, the scanning distance is 100μm, the spot diameter is 100μm, the layer thickness is 2μm, the interl...

Embodiment 3

[0060] This embodiment provides a method for preparing a high-strength and tough magnesium rare-earth alloy by selective laser melting additive manufacturing technology, and specifically adopts the following steps:

[0061] 1) Mg-19.89Gd (wt.%) alloy powder was prepared by gas atomization, and the alloy powder was sieved, and the powder of 500 mesh or more (average particle size of 34 μm) was selected for selective laser melting molding.

[0062] 2) Dry the powder in a vacuum drying oven at 150°C / 4h, then put it into the powder bed of the selective laser melting equipment, and preheat the substrate to 100°C, pass in the protective gas argon for gas circulation, and wait for the molding chamber Indoor oxygen and water vapor content is lower than 100ppm to start selective laser melting molding.

[0063] 3) The laser power used in the selective laser melting molding is 160W, the scanning speed is 1000mm / s, the scanning distance is 50μm, the spot diameter is 65μm, the layer thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com