Old furnace rising device and rising method thereof

A kiln and old technology, applied in the direction of lifting device, lifting frame, transportation and packaging, etc., can solve the problems of difficulty in increasing production, low output, backward technology, etc., and achieve low production cost, improved utilization, and technical requirements. low difficulty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

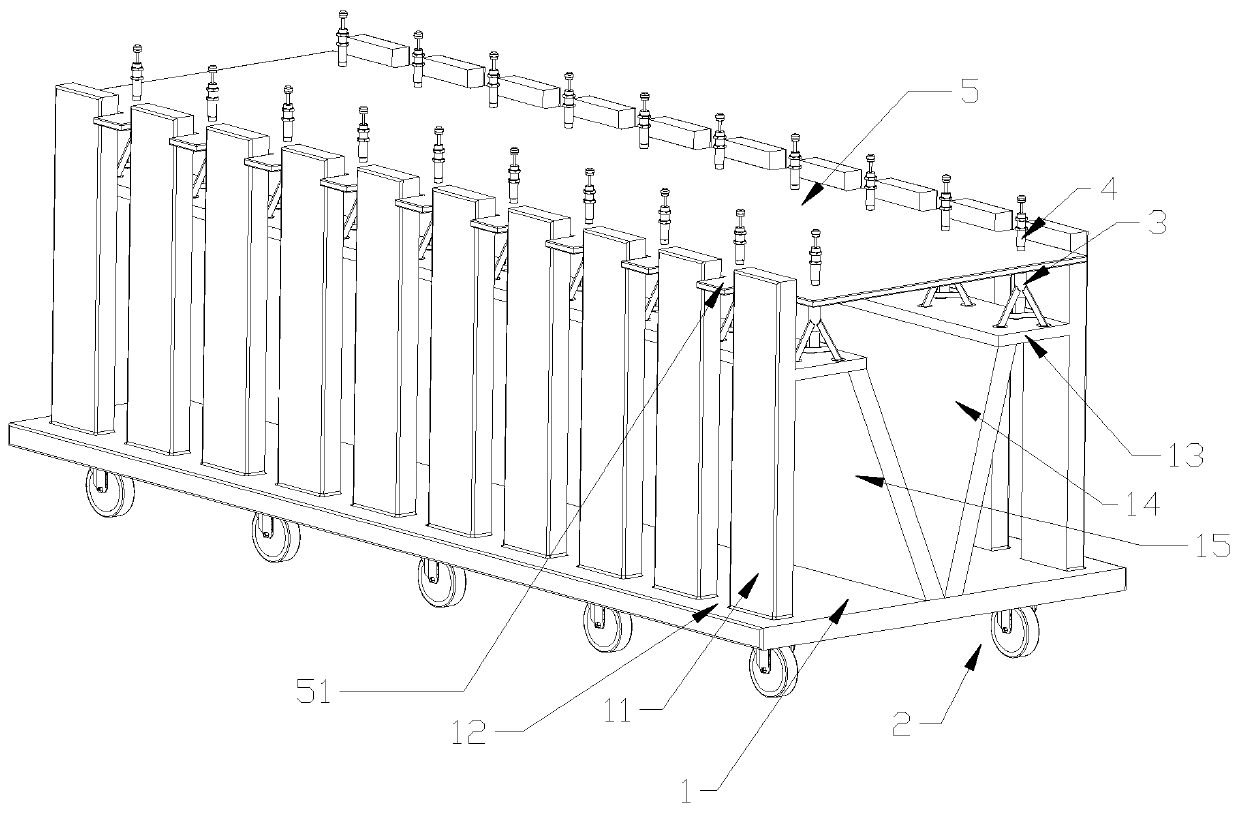

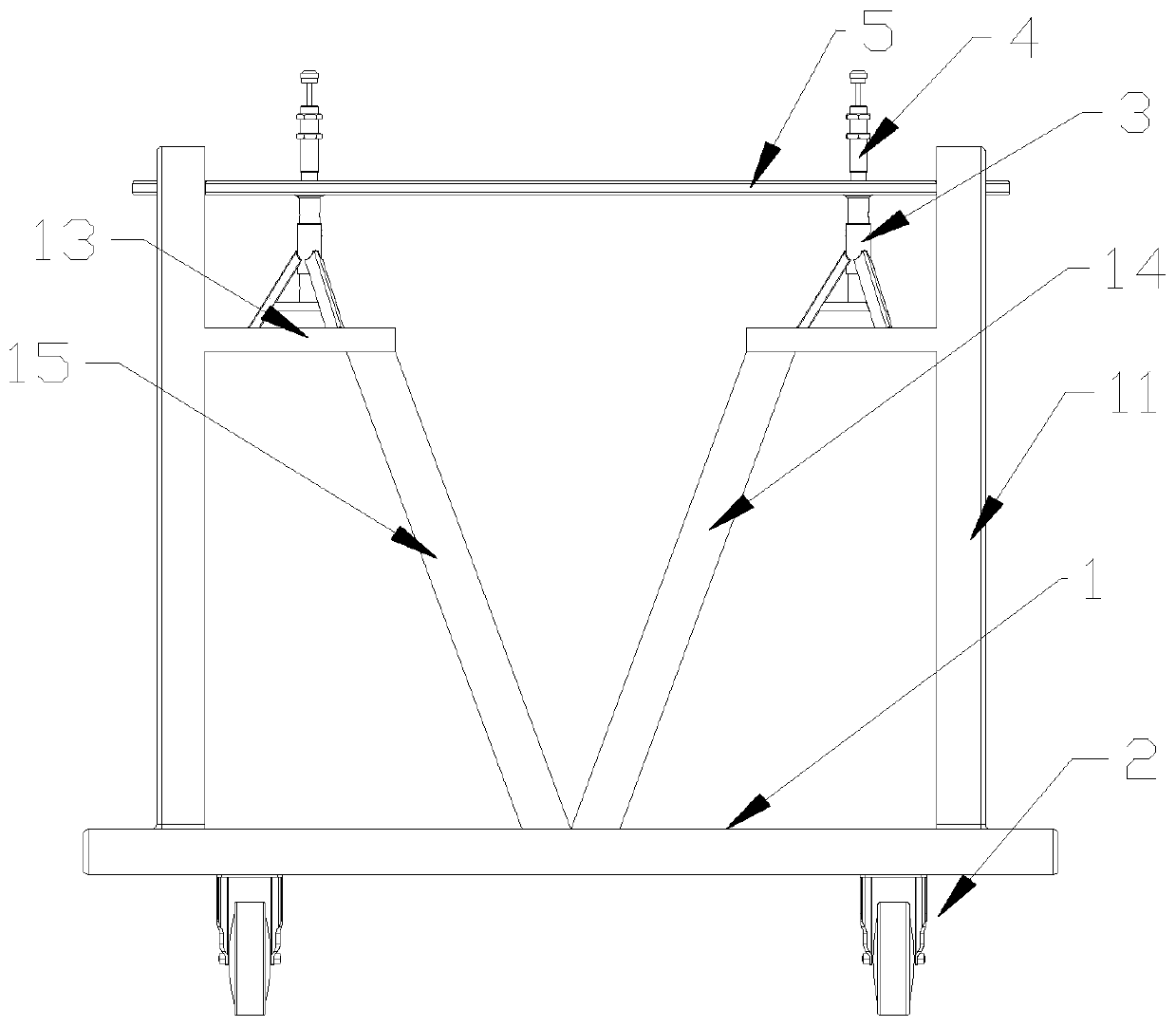

[0039] A method for raising an old furnace raising device includes the following steps:

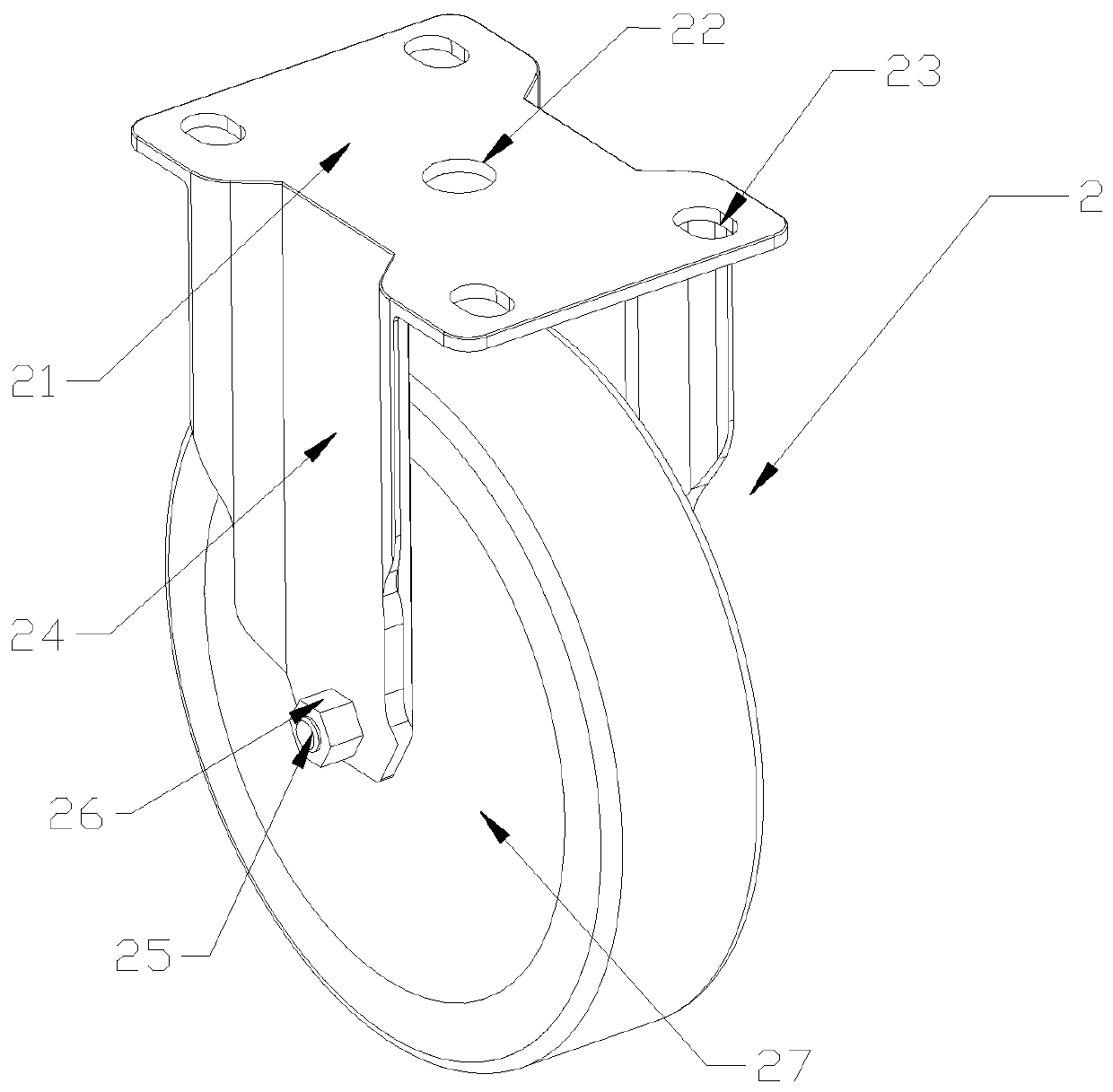

[0040] Step 1: Use a single 50t mechanical jack to fix on the jack platform plate 13, use the walking wheel 2 to push the device into the kiln room, and connect multiple devices to reach the length of the kiln room.

[0041] Step 2: Cut and separate the reinforced concrete structural column of the kiln body from the ring beam and the roof, and chisel out the ends of the steel bars. Jacks 3 and 4 will lift the kiln roof as a whole.

[0042] Step 3: After the kiln roof is fully jacked up and re-welded, high-grade concrete is poured, and the cast-in-situ beams and slabs of the kiln roof are cut in sections at intervals to leave the ends of the steel bars, and the ends of the steel bars are raised to the required sections by lifting mechanical devices. height.

[0043] Step 4: Masonry walls, welding steel bars, pouring high-grade concrete, and repairing the main and branch pipelines after all the kil...

Embodiment 2

[0045] Using a single 50t mechanical jack, 20 sets of synchronous work to make a jacking mechanism, cut the kiln body reinforced concrete structural column, ring beam and roof, cut apart, chisel out the end of the steel bar, re-weld after jacking, and cast high Marked concrete. The cast-in-situ beams and slabs of the kiln roof are cut into sections at intervals of 7 meters to leave the ends of the steel bars, and the ends are raised to the required height by lifting mechanical devices. The walls are built, steel bars are welded, and high-grade concrete is poured. After all the kiln body has been raised, repair the main and branch pipelines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com