Foaming composite material for bicycle safety helmet, and preparation method thereof

A composite material and bicycle technology, applied in helmets, applications, helmet covers, etc., can solve problems such as leakage and precipitation, and achieve the effects of simple preparation process, puncture prevention, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

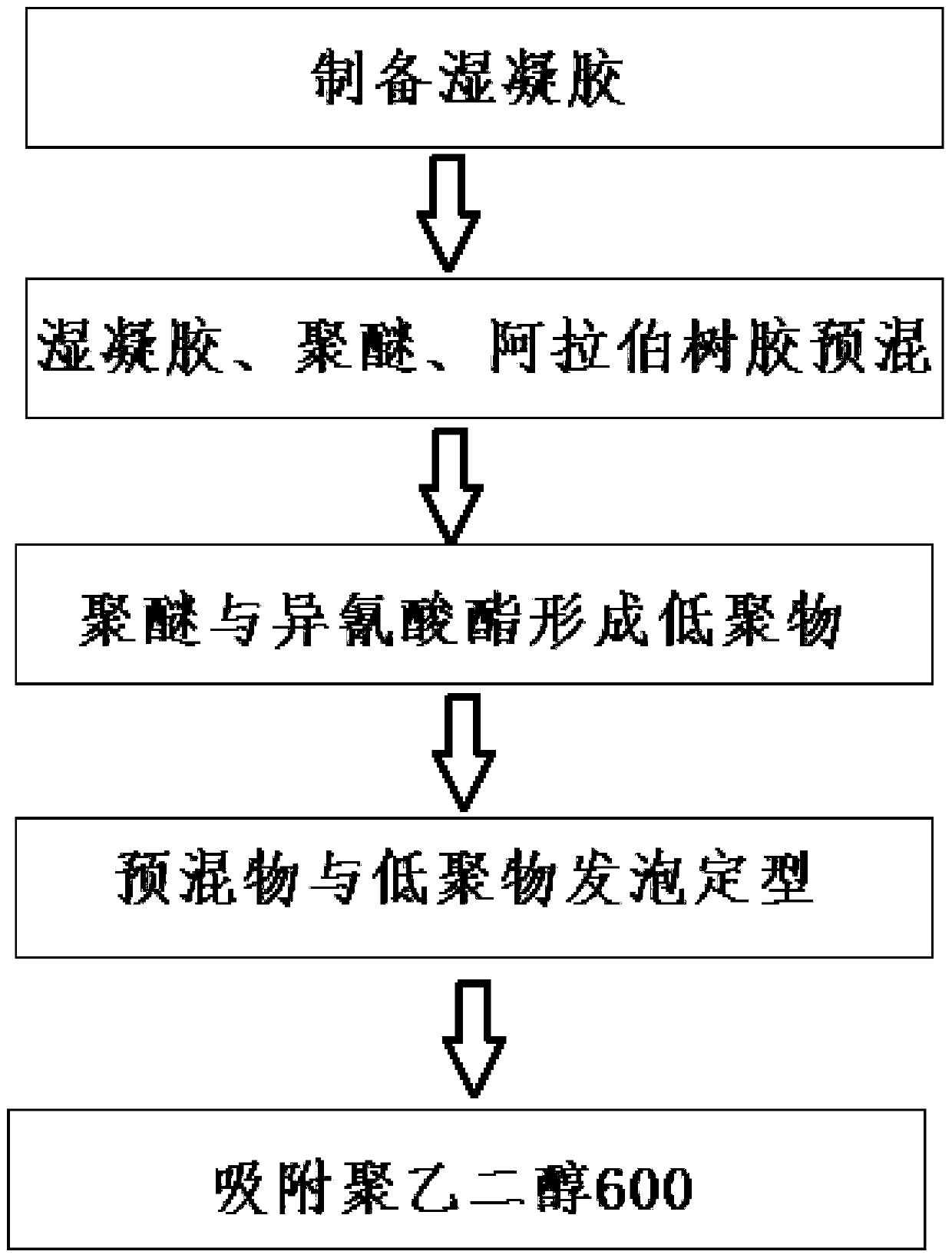

Method used

Image

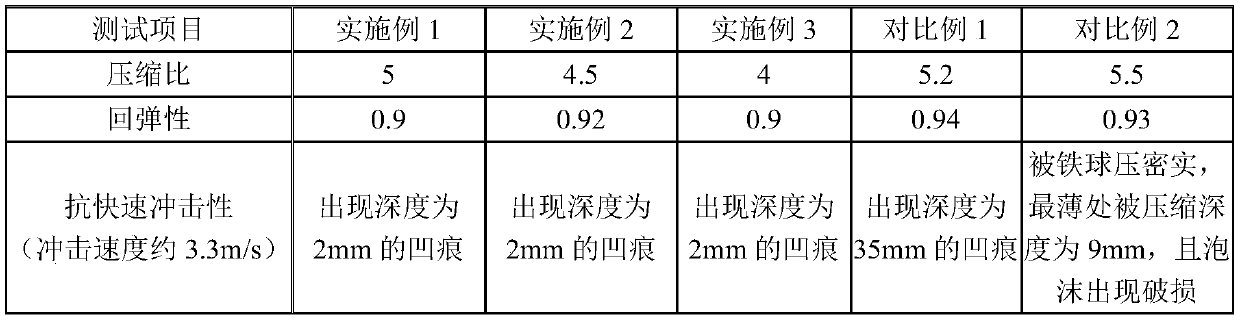

Examples

Embodiment 1

[0030] (1) Add ethyl orthosilicate to the reaction kettle, then add water and ethanol, the mass ratio of ethyl orthosilicate, water, and ethanol is 1:3:5, add hydrofluoric acid while stirring, and adjust the pH of the solution The value is 3, stirred for 1 hour until the tetraethyl orthosilicate is completely hydrolyzed, filtered through filter paper, naturally filtered for 30 minutes, and most of the water was filtered out to obtain a wet gel, and then polyether 330 and gum arabic powder were added to obtain a premix; Gel, polyether, and gum arabic powder are mixed in a mass ratio of 10:20:10;

[0031] (2) Weigh polyether 330, toluene diisocyanate, premix, catalyst stannous octoate, and surfactant silicone oil according to mass ratio: 50:30:50:0.1:0.5; weigh polyether 330 and toluene diisocyanate Pre-react for 30 minutes to form an oligomer with isocyanate at the end; then add the premix, catalyst and surfactant and stir evenly, then quickly add a plate-shaped mold with a thi...

Embodiment 2

[0034] (1) Add ethyl orthosilicate to the reaction kettle, then add water and ethanol, the mass ratio of ethyl orthosilicate, water, and ethanol is 1:4:3, add hydrofluoric acid while stirring, and adjust the pH of the solution The value is 3, stirred for 1 hour until the tetraethyl orthosilicate is completely hydrolyzed, filtered through filter paper, naturally filtered for 30 minutes, and most of the water was filtered out to obtain a wet gel, and then polyether 330 and gum arabic powder were added to obtain a premix; Gel, polyether, and gum arabic powder are mixed in a mass ratio of 10:20:5;

[0035](2) Polyether 330, toluene diisocyanate, premix, catalyst dibutyltin dilaurate, and surfactant silicone oil are weighed according to the mass ratio of materials: 50:35:60:0.2:1; Polyether 330 and Toluene diisocyanate is pre-reacted for 45 minutes to form an oligomer with isocyanate at the end; then add the premix, catalyst and surfactant and stir evenly, then quickly add a plate-...

Embodiment 3

[0038] (1) Add ethyl orthosilicate to the reaction kettle, then add water and ethanol, the mass ratio of ethyl orthosilicate, water, and ethanol is 1:5:5, add hydrofluoric acid while stirring, and adjust the pH of the solution The value is 3, stir for 2 hours until the tetraethyl orthosilicate is completely hydrolyzed, filter paper, filter naturally for 30 minutes, filter out most of the water, and obtain a wet gel, then add polyether 330 and gum arabic powder to obtain a premix; wet Gel, polyether, and gum arabic powder are mixed in a mass ratio of 15:25:10;

[0039] (2) Weigh polyether 330, isophorone diisocyanate, premix, catalyst stannous octoate, and surfactant silicone oil in a mass ratio of 50:30:55:0.1:0.5 to weigh materials; polyether 330 Pre-react with isophorone diisocyanate for 30 minutes to form an oligomer with isocyanate at the end; then add the premix, catalyst and surfactant and stir evenly, then quickly add a plate-shaped mold with a thickness of 10mm to foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com