Modified corn straw flame-retardant degradable foam material and preparation method thereof

A technology of corn stalks and foaming materials, which is applied in the field of foaming materials, can solve the problems of flammability, unsatisfactory mechanical properties and application properties, and low product strength, and achieve low preparation costs, good flame retardancy, and considerable economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

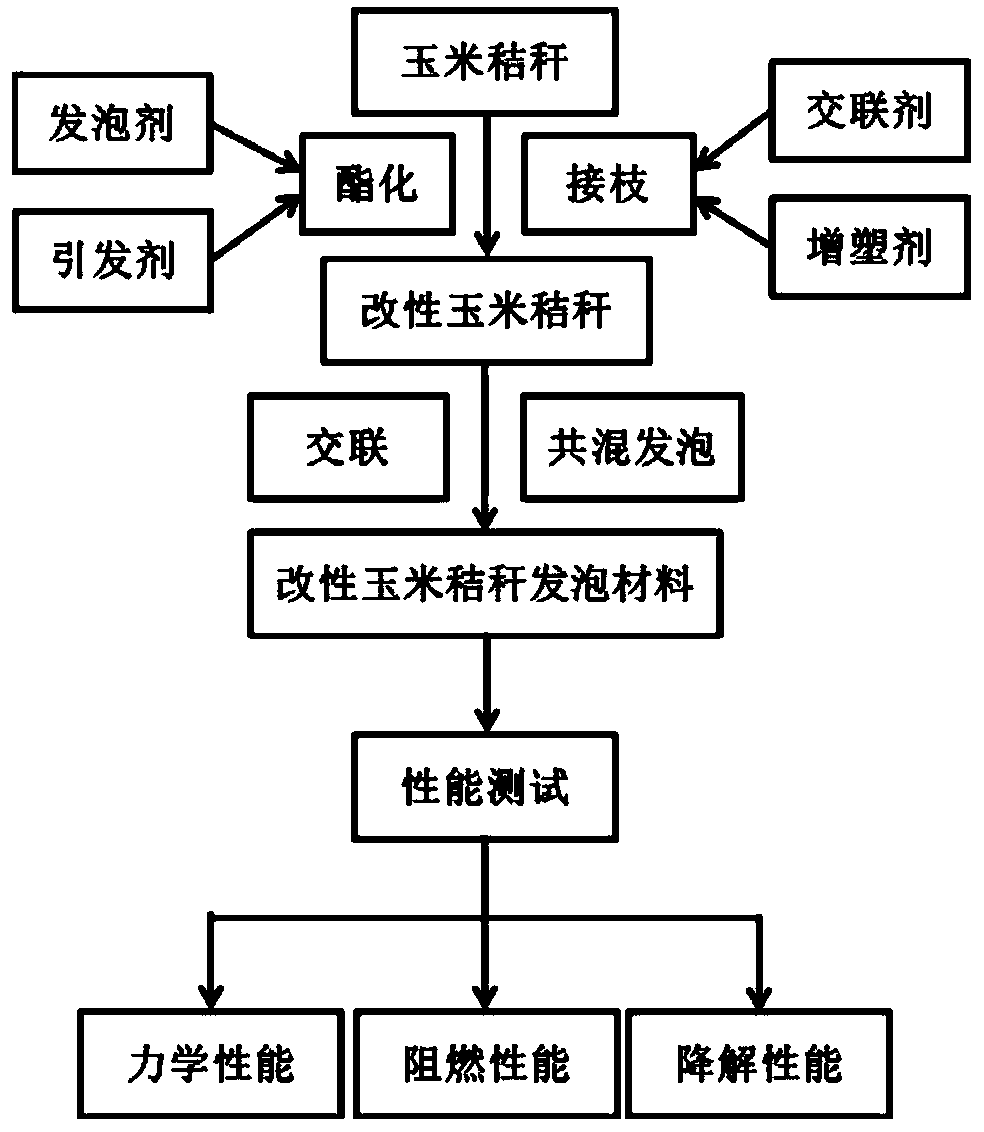

[0040] In order to improve the various performances of the existing corn stalk foaming materials and break through the limitations of the use of the existing corn stalk foaming materials, the present invention provides a modified corn stalk foaming material with good comprehensive performance and the foaming material Preparation. The specific preparation process includes the following steps.

[0041] Step 1: Esterifying and grafting the corn stalks to obtain the esterification-grafting modified corn stalks.

[0042] In the present invention, a kind of modified corn stalks capable of preparing foaming materials with good flame retardant properties is provided, which is prepared by esterification and graft modification of corn stalks, and the preparation of esterification-grafting modified corn stalks includes The following steps:

[0043] Step 1, pretreating corn stalks;

[0044] Step 2, esterifying the pretreated corn stalks to obtain esterified corn stalks;

[0045] Step ...

Embodiment 1

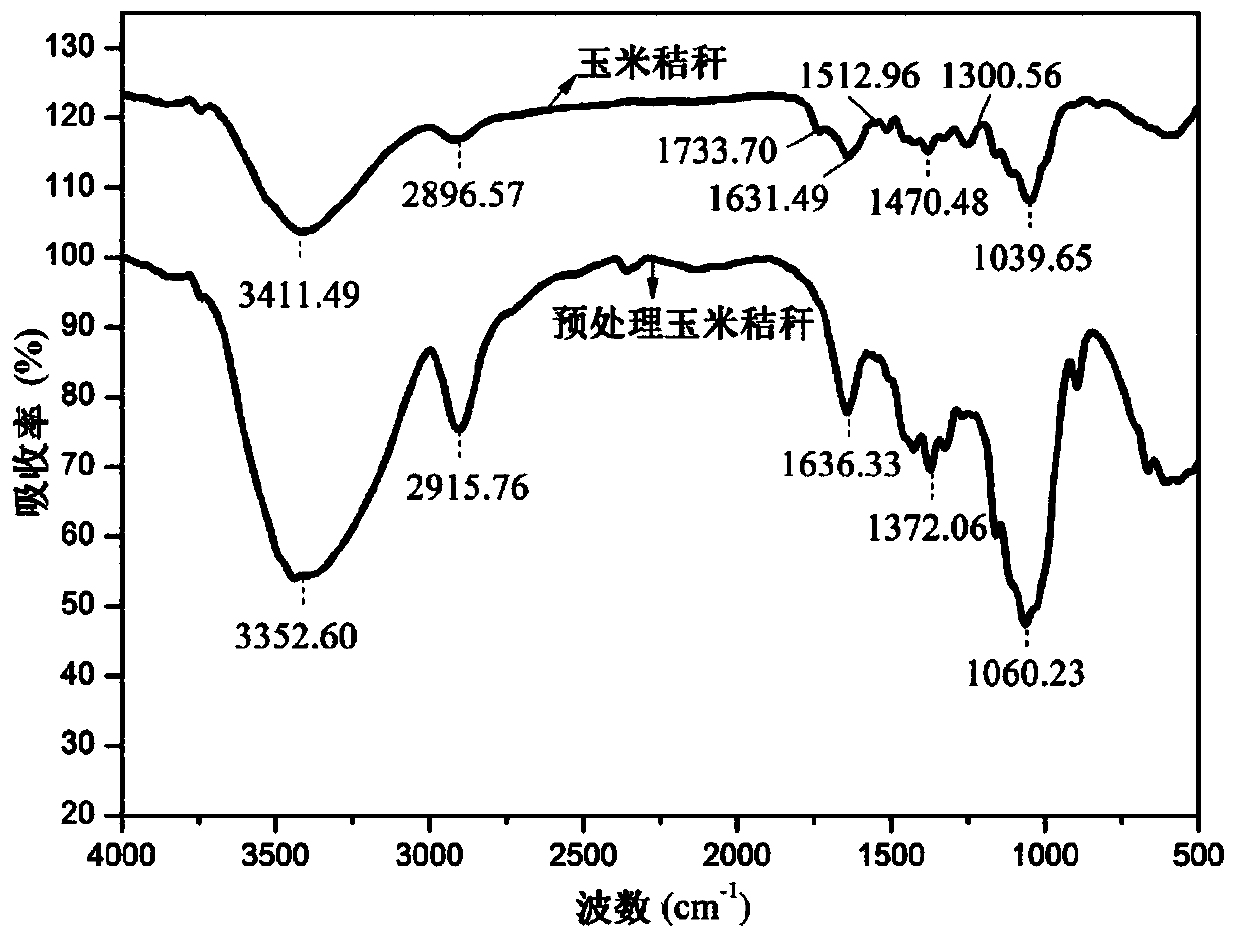

[0109] Prepare pretreated corn stover:

[0110] The corn stalks are washed with clean water, dried, crushed, and passed through a 100-mesh standard sieve to obtain corn stalk powder. Add corn stalk powder into a mixed solution of an appropriate amount of 2.5mol / L sodium hydroxide solution and 0.4mol / L anhydrous sodium sulfite solution, the molar ratio of sodium hydroxide and anhydrous sodium sulfite is 5:1, boil and reflux for 7h.

[0111] After the reaction, the reaction solution was cooled to room temperature, and the reaction solution was filtered with suction, washed with deionized water and filtered 5 times, rinsed with absolute ethanol, and vacuum-dried at 80°C for 4 hours to obtain pretreated corn stalks .

Embodiment 2

[0113] Preparation of esterification-grafted modified corn stover:

[0114] Add 1 mol of imidazole formic acid to 1.2 mol of thionyl chloride while stirring, and reflux at 60°C for 5 hours to obtain imidazole formic acid chloride.

[0115] Weigh 3.9g of the pretreated corn stalks of Example 1, 9.5g of imidazole formyl chloride and 8g of triethylamine into a reaction kettle, add 300mL of N,N-dimethylformamide, heat to 40°C, and stir evenly. Then add 0.5g of 4-dimethylaminopyridine, heat to 55°C for esterification reaction for 6 hours, suction filter after the reaction, wash with deionized water and absolute ethanol three times each, and dry in a vacuum oven at 80°C for 3 hours Finally, the esterified corn stalks are obtained and placed in a desiccator for subsequent use.

[0116] Take the above product and add it to 2.6g of chloropropene, stir it magnetically, heat it to 65°C for grafting reaction, carry out the reaction for 24 hours, remove excess chloropropene by rotary evap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Rebound rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com