Anticorrosive powder coating for outdoor metal guardrails and preparation method thereof

A powder coating and metal technology, applied in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems that anti-corrosion materials such as glass flakes and stainless steel flakes cannot be applied, affect the decorative effect and service life of the guardrail, and cannot maintain the sheet structure. , to achieve the effect of improving anti-corrosion effect, reducing shrinkage stress and improving microscopic defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

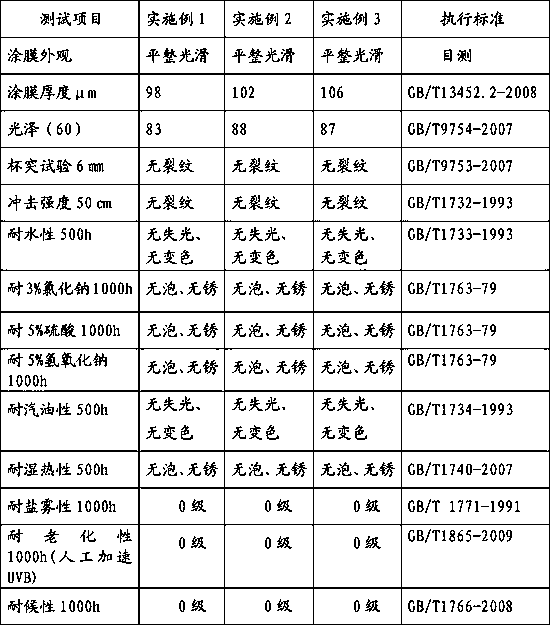

Examples

Embodiment 1

[0026] Embodiment 1: a kind of preparation method of anticorrosion powder coating for outdoor metal guardrail: comprise the following steps:

[0027] Add 47kg of carboxyl-terminated polyester with an acid value of 29, TGIC 3.5kg, rutile titanium dioxide 6kg, precipitated barium sulfate 15kg, benzoin 0.9kg, leveling agent GLP288 0.9kg, brightening agent 701 0.7kg, light stable Add 0.15kg of agent 144, 0.3kg of phthalocyanine blue and 0.8kg of coupling agent w6050, put them into the mixer in turn, mix for 15 minutes at 300 rpm, and stir evenly;

[0028] b. The mixed material is transported to the extruder through the feeder for melt mixing and dispersion extrusion. The temperature of the extruder is controlled at 115-105°C in zone I and 100-90°C in zone II;

[0029] c. The melted and mixed extruded materials are pressed into flake-like and easily crushed materials by the tablet cooling roller, and then crushed into small flake-like materials by the crusher;

[0030] d. After ...

Embodiment 2

[0033] Embodiment 2: preparation method is just that each component weight is with embodiment 1:

[0034] The base powder is composed of the following components in parts by weight:

[0035] 46kg of carboxyl-terminated polyester with an acid value of 25, TGIC 3.4kg, rutile titanium dioxide 6kg, precipitated barium sulfate 12kg, benzoin 0.9kg, leveling agent GLP288 0.9kg, brightening agent 701 0.7kg, light stabilizer 144 0.15kg, pigment phthalocyanine blue 0.2kg and coupling agent w6050 0.8kg.

[0036] The components of the raw materials are by weight: 0.4kg of bonding wax powder, 4kg of glass flakes, and 0.1kg of alumina C.

Embodiment 3

[0037] Embodiment 3: preparation method is just that each component weight is with embodiment 1:

[0038] The base powder is composed of the following components in parts by weight:

[0039] Carboxy-terminated polyester with an acid value of 30 45kg, TGIC 3.3kg, rutile titanium dioxide 6kg, precipitated barium sulfate 12kg, benzoin 0.9kg, leveling agent GLP288 0.9kg, brightening agent 701 0.7kg, light stabilizer 144 0.15kg, phthalocyanine blue 0.2kg and coupling agent w6050 0.8kg.

[0040] The components of the raw materials are by weight: 0.4kg of bonding wax powder, 4kg of glass flakes, and 0.1kg of alumina C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com