Preparation method of high-density yeast fermentation liquor

A yeast fermentation, high-density technology, applied in the direction of fungi, etc., can solve the problems of unfavorable industrialization development, high production costs, complicated procedures, etc., and achieve the effect of reducing the content of sulfate ions, less water for production, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

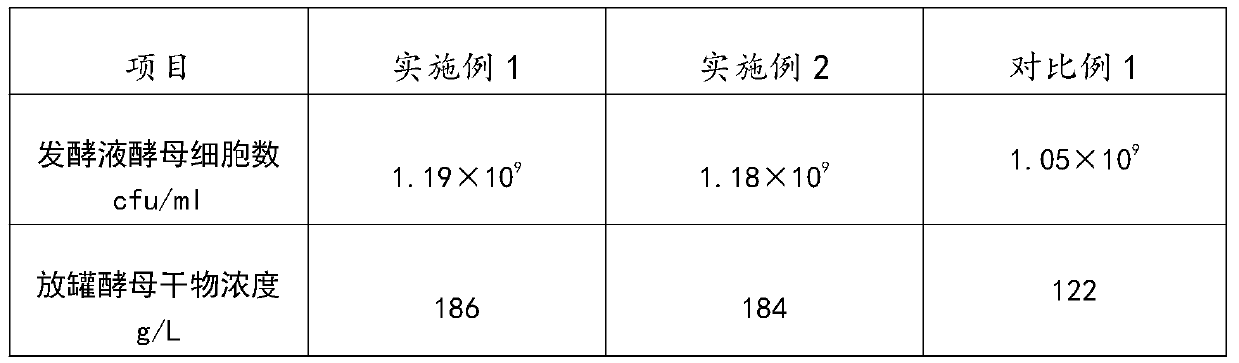

Examples

Embodiment 1

[0039] A preparation method of high-density yeast fermentation broth, the specific operation method is as follows:

[0040] (1), preparation of dilute compound nutrient solution and concentrated compound nutrient solution:

[0041] Crush 95kg of corn and 5kg of soybean meal, add 200kg of water to make a slurry, adjust the pH to 6.0, add 0.04kg of high-temperature amylase, and enzymatically hydrolyze at 90°C for 1 hour; cool down to 55°C, adjust the pH to 5.2, and add 0.04kg of saccharification Enzyme, keep warm for 5 hours; adjust the pH value to 4.8, add 0.06kg of protease, keep warm for 15 hours to make a liquid enzymatic solution;

[0042] Filtrate the liquid enzymatic solution to obtain 260 kg of filtrate, which is the dilute compound nutrient solution. After the dilute compound nutrient solution is evaporated and concentrated under reduced pressure, 163 kg of concentrated compound nutrient solution is obtained, with a solid content of 44%.

[0043] (2), the production me...

Embodiment 2

[0047] A preparation method of high-density yeast fermentation broth, the specific method is as follows:

[0048] (1), preparation of dilute compound nutrient solution and concentrated compound nutrient solution:

[0049] Grind 1850kg of corn and 150kg of soybean meal, add 4400kg of water to make a slurry, adjust the pH value to 6.0, add 0.8kg of high-temperature amylase, enzymatic hydrolysis at 90°C for 1 hour; cool down to 55°C, adjust the pH value to 5.2, add 0.8 kg of glucoamylase, heat preservation enzymolysis for 5 hours; adjust the pH value to 4.8, add 1.2kg of protease, heat preservation enzymolysis time 15 hours; obtain the filtrate 5416kg through filtration, which is the dilute compound nutrient solution. The concentrated compound nutrient solution is 3520kg, and the solid content is 40%.

[0050] (2), the production method of high-density yeast liquid is as follows:

[0051] ①. In a 2m3 fermentation tank, dilute 25kg of dilute compound nutrient solution to 0.9m3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com