Production process of high quality biodiesel

A technology of biodiesel and production process, which is applied in the petroleum industry, biofuel, liquid carbon-containing fuel, etc., to achieve the effect of high fatty acid methyl ester content and low metal ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

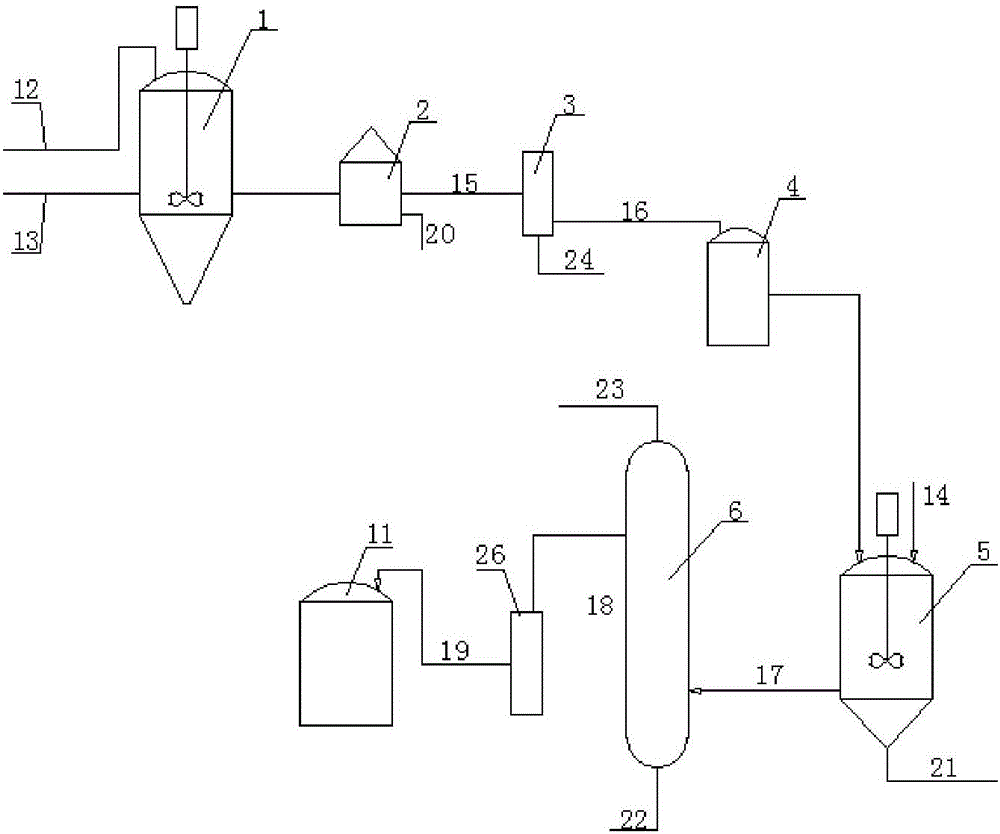

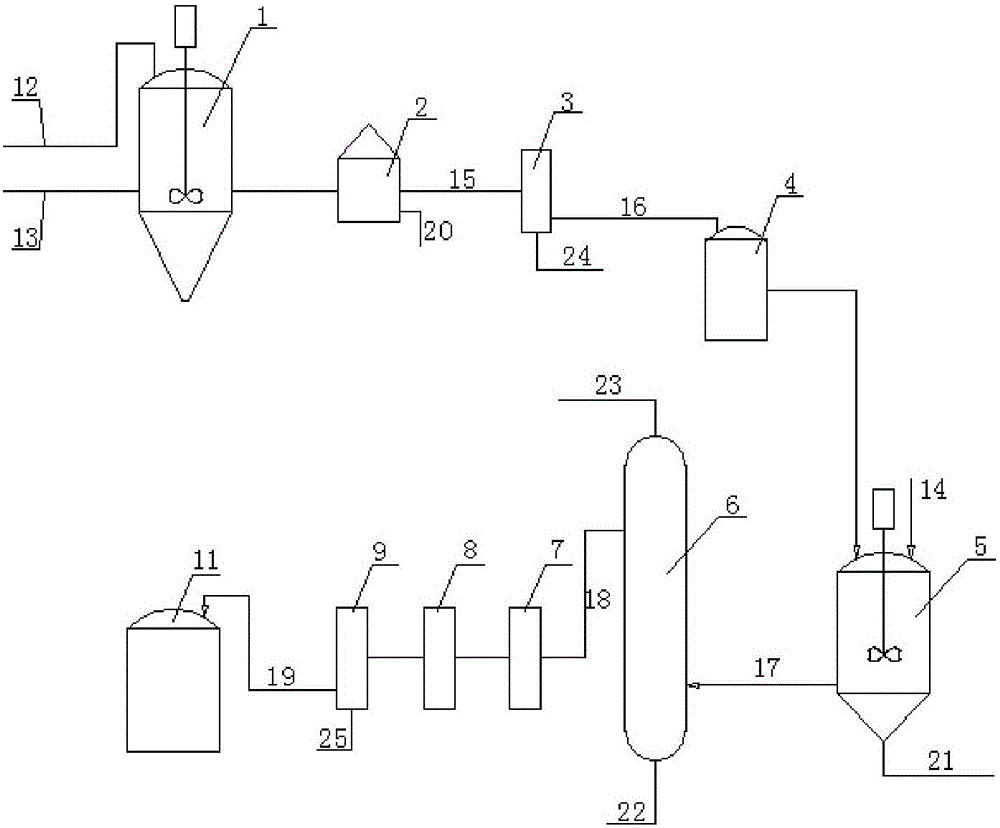

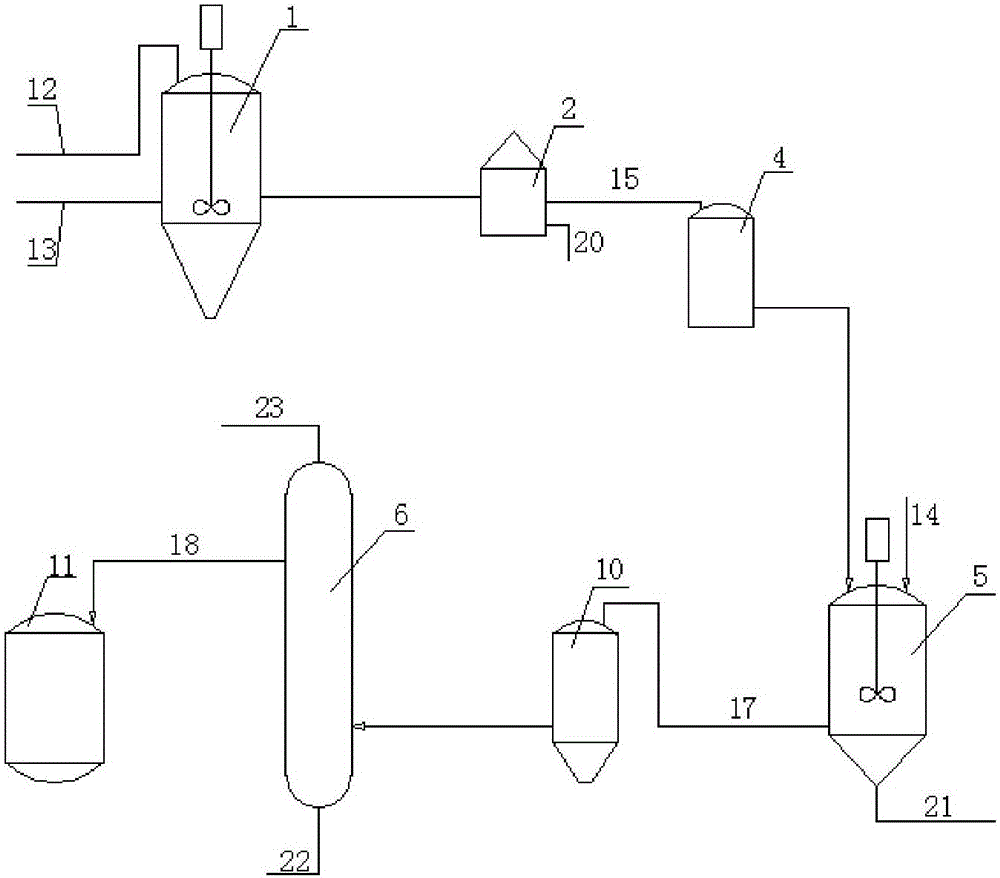

Method used

Image

Examples

Embodiment 1

[0047] The acidified soybean oil is hydrated and degummed to obtain the degummed raw oil, and the refined raw oil with a water content of 0.03% is obtained through the primary microfiltration device and stored in the raw oil storage tank. The microfiltration membrane material is polytetrafluoroethylene with a pore size of 1 μm. The pressure difference is 0.02MPa, and the filtration mode is dead-end filtration.

[0048] Refined raw oil and anhydrous methanol in solid sulfuric acid catalyst SO 4 2- / ZrO 2 Under the action of the alkali catalyst sodium hydroxide, an esterification-transesterification reaction occurs in the reactor. After the reaction is completed, the glycerin-containing wastewater and crude biodiesel are separated, and the crude biodiesel enters the vacuum distillation tower for distillation. The vacuum distillation conditions are: The vacuum pressure is 10Pa, and the fraction at 180~250℃ is cut as biodiesel.

[0049] The above-mentioned biodiesel is then refined by ...

Embodiment 2

[0051] The process conditions are the same as in Example 1, except that the raw material oil is waste oil, the microfiltration membrane material is polyvinylidene fluoride, and the pore size of the microfiltration membrane is 0.5 μm. The properties of the prepared biodiesel are shown in Table 1.

Embodiment 3

[0053] The process conditions are the same as in Example 1, except that the raw oil is waste oil, the microfiltration membrane material is polyethylene, and the pore size of the microfiltration membrane is 5 μm. The properties of the prepared biodiesel are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com