Preparation method of squid ink bioactive peptide

A technology of squid ink and active peptide, which is applied in the field of biological extraction, can solve the problems of squid leftovers polluting the environment, etc., and achieve the effects of complete protein decomposition, convenient processing, and high enzymatic hydrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

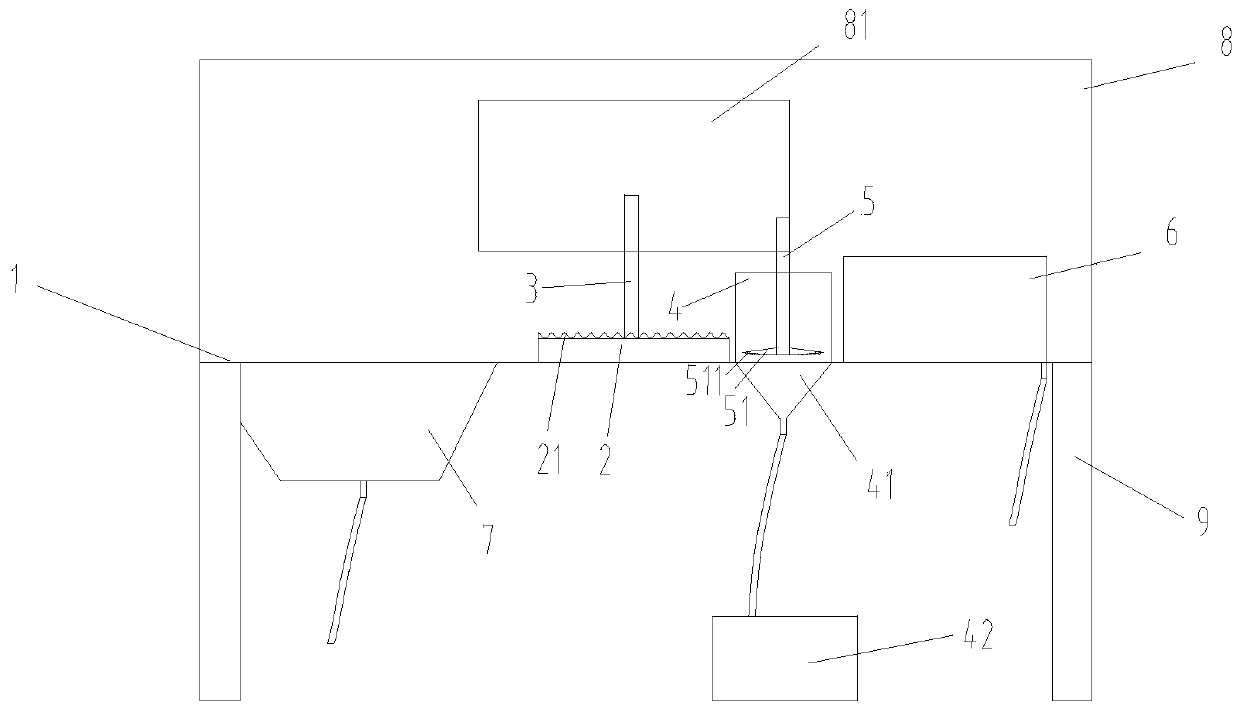

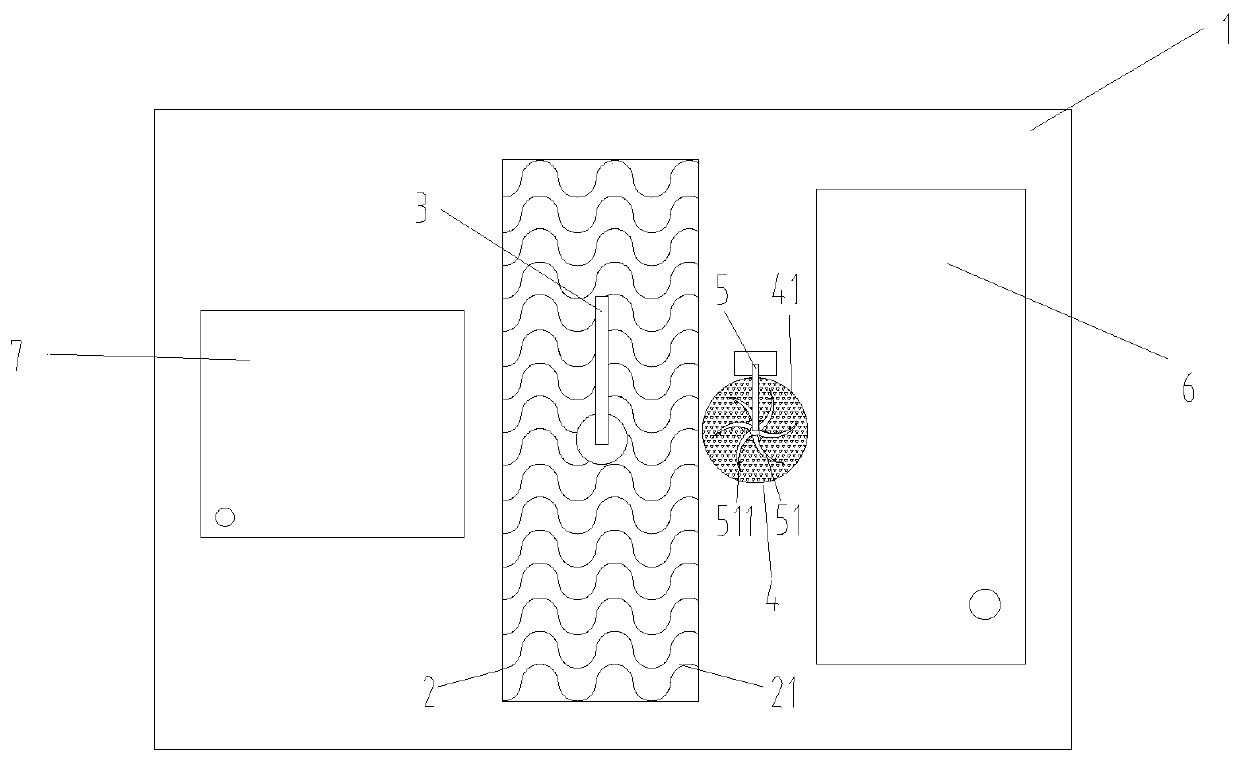

Image

Examples

Embodiment 1

[0026] (a) Squid ink collected in the above-mentioned squid processing device;

[0027](b) Mix squid ink and water at a volume ratio of 1:20, adjust the pH value to 1, use 0.1% pepsin to enzymatically hydrolyze at 30 °C for 3 h, then adjust the pH value to 7, and use 0.1% compound protease to enzymatically digest at 50 °C Decompose 1 h, the mass ratio of composite protease is alkaline protease: papain: flavor protease=1:2:4, makes enzymolysis liquid, centrifuges 15 min under 6000 rpm and gets supernatant;

[0028] (c) Add 2 times the volume of 5% (m / v) trichloroacetic acid solution to the supernatant of the enzymatic hydrolysis solution, mix well and let stand at room temperature for 60 min, centrifuge to get the supernatant, dialyze and desalt, Freeze-drying to obtain squid ink active peptide.

Embodiment 2

[0030] (a) Squid ink collected in the above-mentioned squid processing device;

[0031] (b) Mix squid ink and water at a volume ratio of 1:15, adjust the pH value to 4, use 0.1% pepsin to enzymatically hydrolyze at 40 °C for 1 h, then adjust the pH value to 9, and use 0.1% compound protease to enzymatically digest at 60 °C Decompose 1 h, the mass ratio of composite protease is alkaline protease: papain: flavor protease=3:4:2, makes enzymolysis liquid, centrifuges 5 min under 8000 rpm to get supernatant;

[0032] (c) Add an equal volume of 20% (m / v) trichloroacetic acid solution to the supernatant of the enzymatic hydrolysis solution, mix well and let stand at room temperature for 60 min, centrifuge to get the supernatant, dialyze and desalt, freeze Dried to obtain squid ink active peptide.

Embodiment 3

[0034] (a) Squid ink collected in the above-mentioned squid processing device;

[0035] (b) Mix squid ink and water at a volume ratio of 1:10, adjust the pH value to 3, use 0.1% pepsin to enzymatically hydrolyze at 35 °C for 2 h, then adjust the pH value to 8, and use 0.1% compound protease to enzymatically digest at 55 °C Decompose 2 h, the mass ratio of compound protease is alkaline protease: papain: flavor protease=1:2:2, makes enzymolysis liquid, centrifuges 5 min under 8000 rpm to get supernatant;

[0036] (c) Add an equal volume of 15% (m / v) trichloroacetic acid solution to the supernatant of the enzymatic hydrolysis solution, mix well and let stand at room temperature for 60 min, centrifuge to get the supernatant, dialyze and desalt, freeze Dried to obtain squid ink active peptide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com