Homogenized alumina ceramic and preparation method thereof

A technology of alumina ceramics and alumina ceramic powder, which is applied in the field of homogenized alumina ceramics and its preparation, can solve the problems of inability to obtain homogenized alumina ceramics, achieve low cost, ensure mechanical properties, and be simple and easy line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

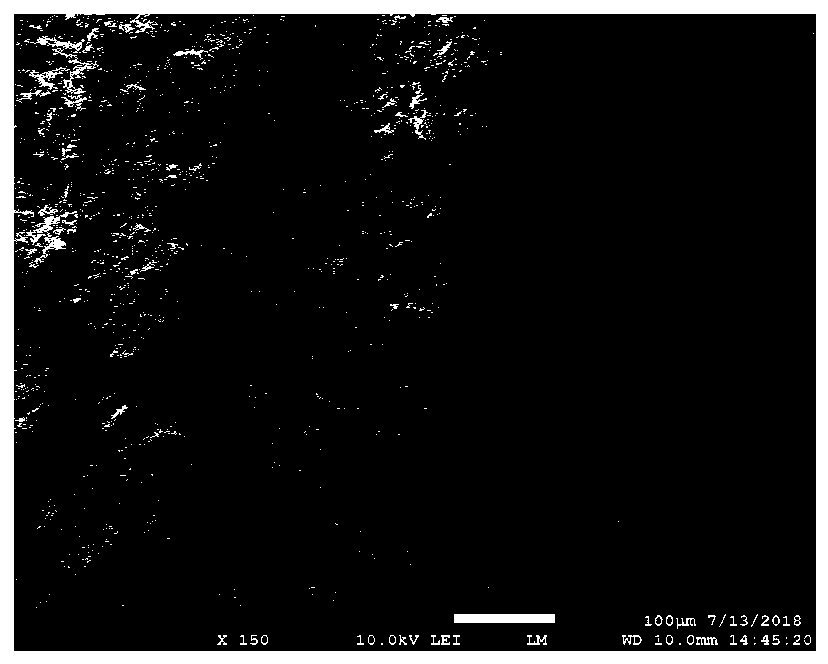

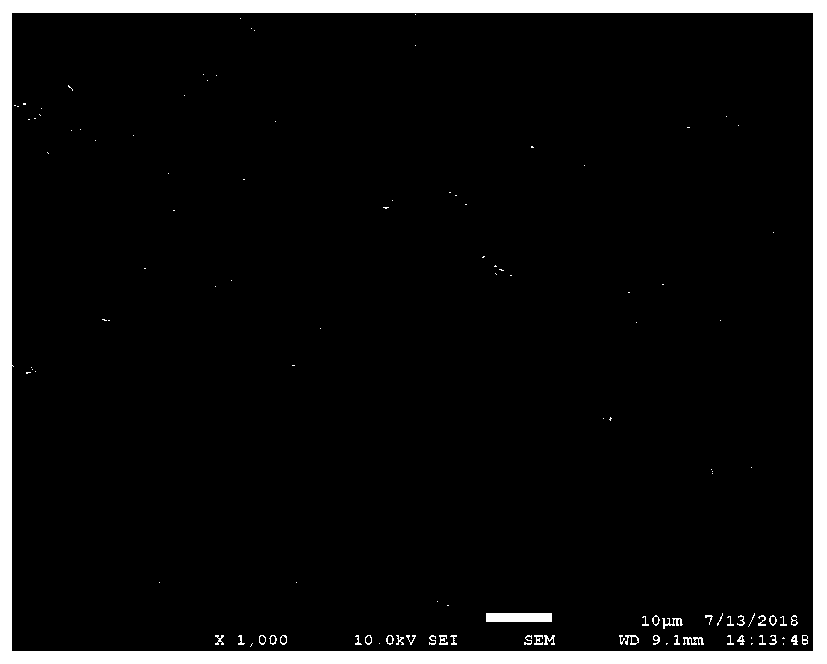

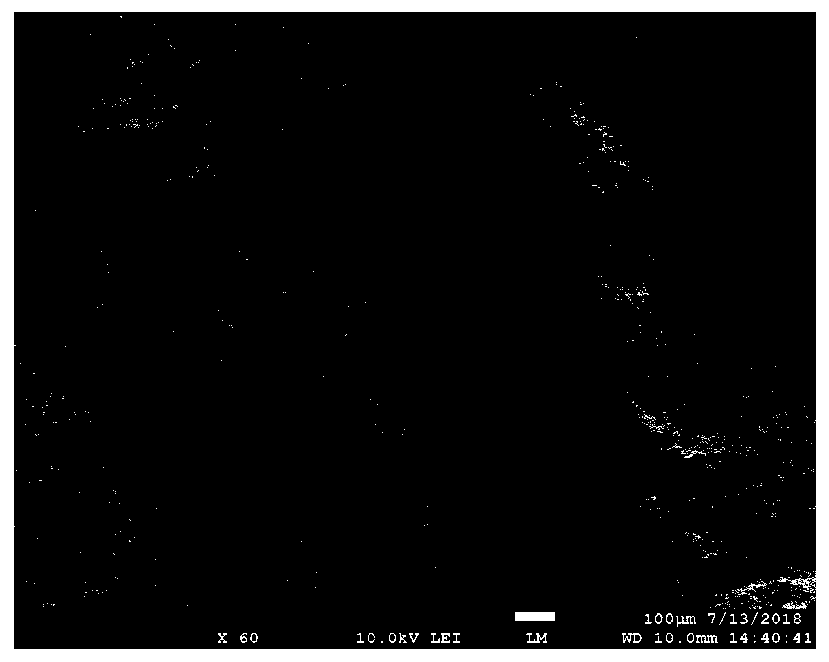

Image

Examples

preparation example Construction

[0030] As mentioned above, the present invention provides a homogenized alumina ceramic and a preparation method thereof.

[0031] In the first aspect, according to an embodiment of the present invention, there is provided a method for preparing homogenized alumina ceramics, the method comprising the following steps:

[0032] S1, preparation of mixed slurry,

[0033] Mix silica sol, water-soluble organic matter and alumina ceramic powder in a certain mass ratio in sequence to obtain a mixed slurry;

[0034] S2, preparing homogeneous alumina ceramics, including:

[0035] injecting the mixed slurry into a mold and controlling the mold to be rapidly suspended in a liquid nitrogen environment, so that the mixed slurry is solidified and formed to obtain a green body;

[0036] The green body is demoulded and post-treated to obtain homogeneous alumina ceramics.

[0037] In the above preparation method, as the liquid phase for preparing the slurry, the silica sol can be alkaline si...

Embodiment 1

[0062] Step 1: Slurry preparation, mixing polyvinylpyrrolidone, silica sol with a concentration of 15wt%, pH of 3.6, and alumina ceramic powder at a mass ratio of 1.1:43.9:55 and ball milling to obtain alumina ceramic slurry; The alumina ceramic powder contains 10wt% of particles with an average particle diameter of 50nm and 90wt% of particles with an average particle size of 50nm, and the ball milling time is 28h.

[0063] Step 2: Preparation of homogeneous alumina ceramics. The above slurry is vacuum degassed for 20 minutes and injected into the mold, and it is quickly suspended in liquid nitrogen and fully solidified for 0.5 hours, then demoulded to obtain the green body; the green body is dried at room temperature for 24 hours, 1500 The homogeneous alumina ceramic material can be prepared by sintering at ℃ for 2 hours.

Embodiment 2

[0065] Step 1: slurry preparation, mixing polyvinylpyrrolidone, silica sol with a concentration of 15wt%, pH of 3.6, and alumina ceramic powder at a mass ratio of 2.5:42.5:55 and ball milling to obtain alumina ceramic slurry; The alumina ceramic powder contains 10wt% of particles with an average particle diameter of 50nm and 90wt% of particles with an average particle size of 50nm, and the ball milling time is 28h.

[0066] Step 2: Preparation of homogeneous alumina ceramics. The above slurry is vacuum degassed for 20 minutes and injected into the mold, and it is quickly suspended in liquid nitrogen and fully solidified for 0.5 hours, then demoulded to obtain the green body; the green body is dried at room temperature for 24 hours, 1500 The homogeneous alumina ceramic material can be prepared by sintering at ℃ for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com