Preparation method of graphene toughened silicon carbide ceramic

A technology of tough silicon carbide and graphene, which is applied in the field of preparation of graphene toughened silicon carbide ceramics, can solve the problems of high sintering temperature, slow densification speed, and low density, and achieve low sintering temperature and fast densification speed , high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

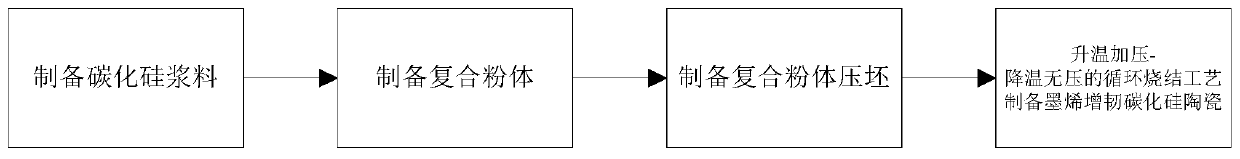

[0056] Such as figure 1 A kind of preparation method of shown graphene toughened silicon carbide ceramics, comprises the following steps:

[0057] (A) mixing silicon carbide powder, graphene powder, sintering aid and solvent and pulverizing to prepare silicon carbide slurry;

[0058] (B) drying and pulverizing the silicon carbide slurry and sieving to prepare a uniformly mixed composite powder;

[0059] (C) packing the composite powder into a mould, applying unidirectional pressure to obtain a composite powder compact;

[0060] (D) Put the mold equipped with the composite powder compact into the sintering furnace, after the furnace temperature rises to the temperature T1, carry out the cyclic sintering process of heating and pressurizing-cooling and pressureless in a vacuum environment to prepare graphene toughened carbonization Silicon ceramics.

[0061] In step (A), 85-99wt% silicon carbide powder, 0.025-5wt% graphene powder and 0.5-10wt% sintering aid are loaded into a b...

Embodiment 2

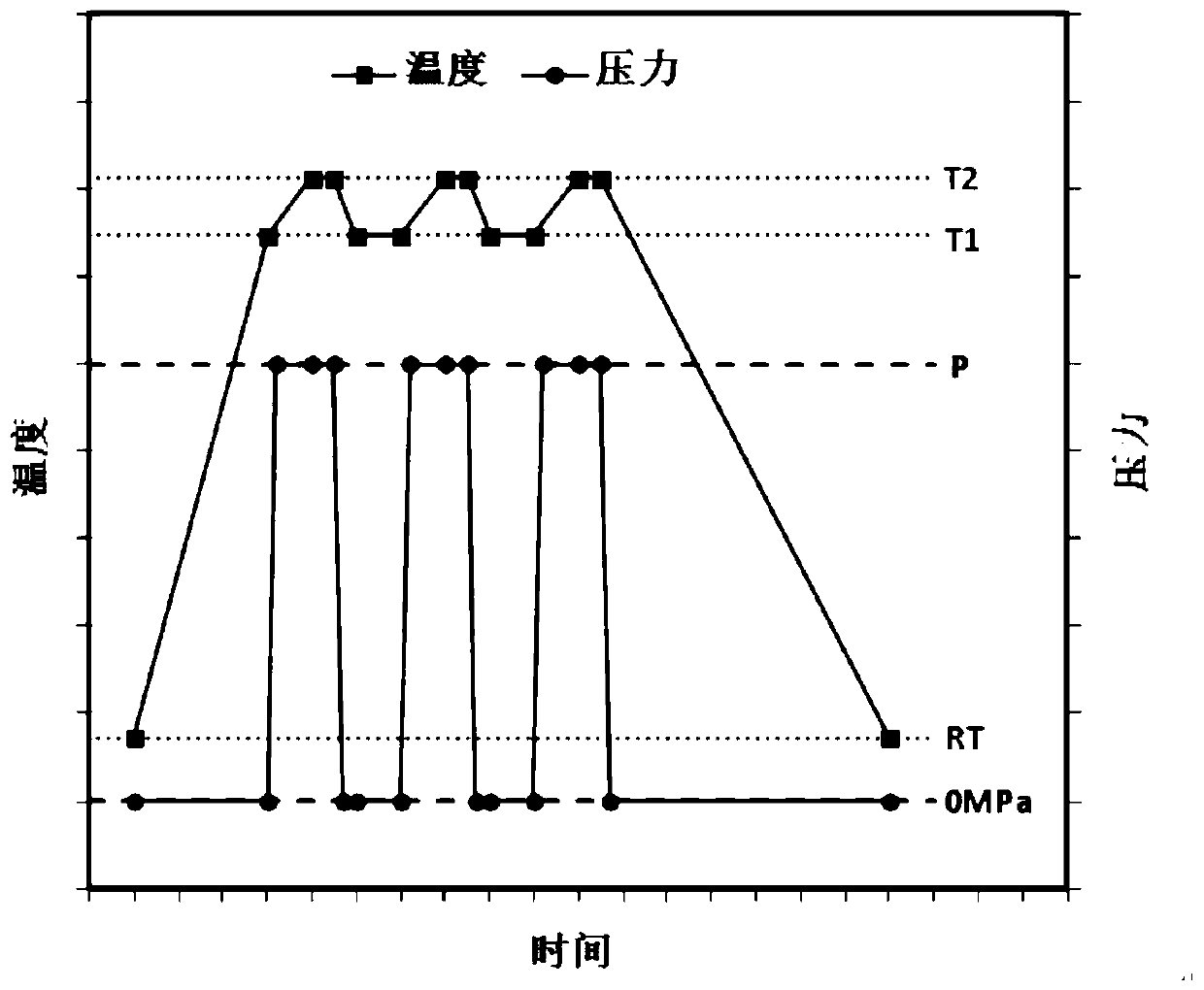

[0070] On the basis of Example 1, in step (D), the cyclic sintering process of described temperature rise and pressure-fall temperature without pressure comprises the following steps:

[0071] (D1) Pressurize the composite powder compact to P, and continue to heat up to T2;

[0072] (D2) holding time t1 at temperature T2;

[0073] (D3) Remove the pressure P applied to the composite powder compact, and lower the temperature to T1;

[0074] (D4) holding time t2 at temperature T1;

[0075] (D5) repeat steps (D1)-(D4);

[0076] In the above steps, the temperature T1 is 1500-1650°C, the temperature T2 is 1750-1900°C, the pressure P is 10-30MPa, the holding time t1 is 10-30min, and t2 is 30-60min.

[0077] In some embodiments, the temperature increase rate from T1 to T2 is 5-10°C / min; the temperature decrease and pressure removal from T2 to T1 are completed within 5 minutes.

[0078] The technical solution can be automatically realized through program setting, the process is sim...

Embodiment 3

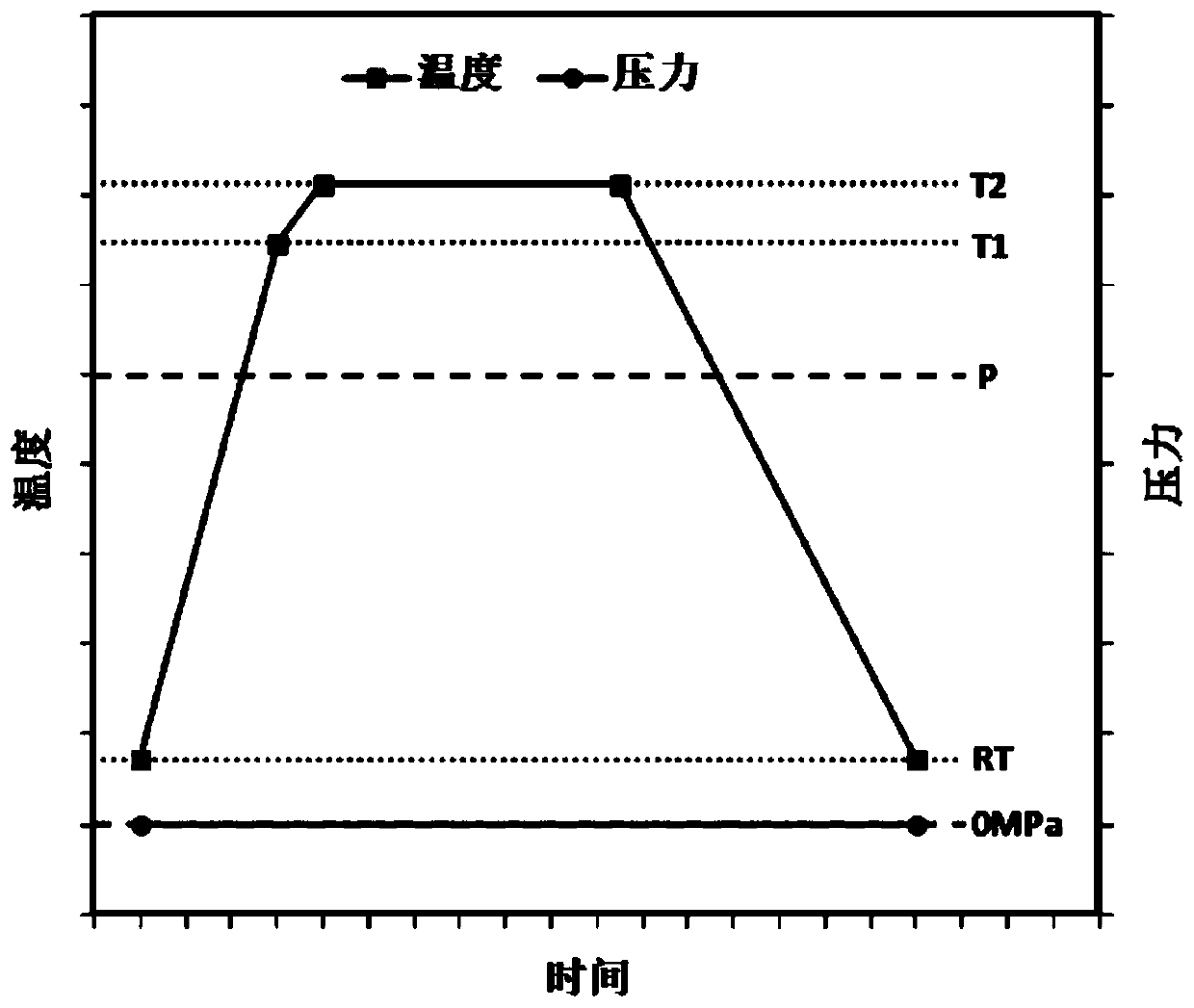

[0081] Such as figure 2 As shown, the present embodiment adopts the following steps to prepare graphene toughened silicon carbide ceramics:

[0082] (A) Put 89 parts of graphene with a particle size of 50nm, 1 part of graphene with a particle size of 1-15 μm and a sheet thickness of 5 nm, 6 parts of alumina with a particle size of 0.5 μm, and 4 parts of yttrium oxide with a particle size of 0.6 μm in a ball mill jar, and add 120 parts of deionized water were ball milled for 24 hours to obtain a uniformly mixed silicon carbide slurry;

[0083] (B) Take out the above-mentioned silicon carbide slurry, place it in a drying oven and dry it at 60°C for 12 hours, and then sieve it with a 40-mesh sampling sieve after crushing to prepare a composite powder of graphene+sintering aid+silicon carbide;

[0084] (C) Put the above-mentioned composite powder into a graphite mould, install a pressure head and apply a unidirectional pressure of 5 MPa on the press to obtain a composite powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Sheet thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com