A kind of synthetic method of aliphatic epoxy compound

An aliphatic epoxy and synthesis method technology, which is applied in the field of synthesis of aliphatic epoxy compounds, can solve the problems of difficult control of the reaction process, easy ring opening of epoxy bonds, expensive catalysts, etc., and achieve the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0034] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

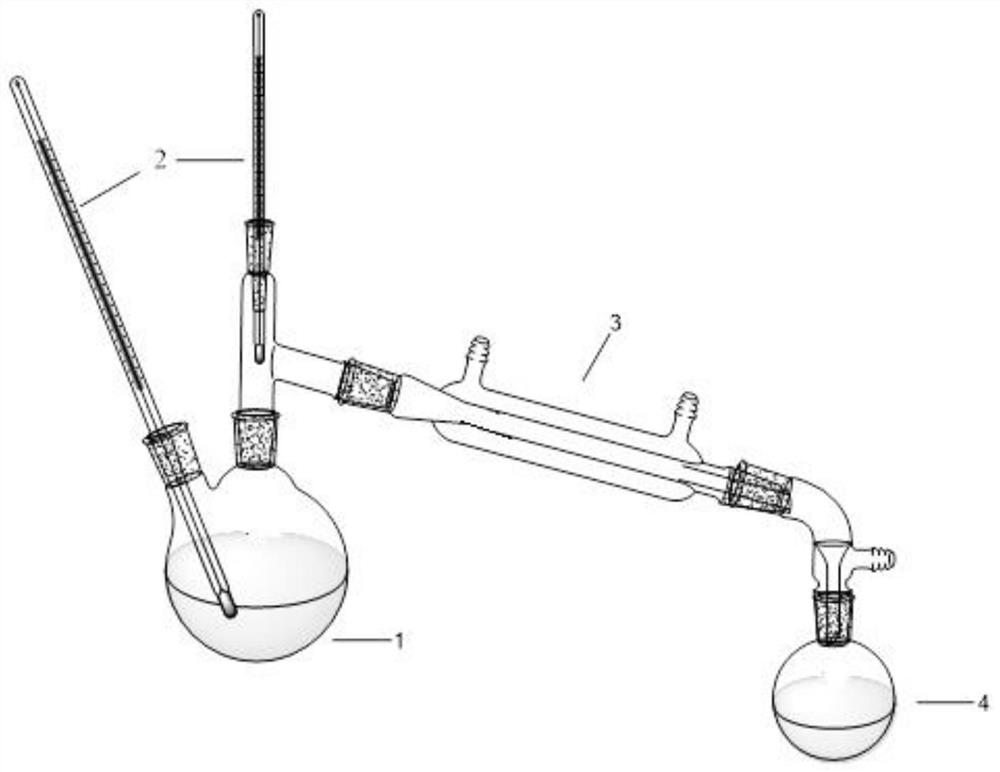

[0035] The reaction apparatus used in the following examples is as figure 1 As shown, it does not limit the protection scope of the present invention, and all reaction bottle devices and reactor type devices having the same process function reactio...

Embodiment 1

[0038] In the there-necked flask of 500ml, add 25.37g 3,4-cyclohexene-1-carboxylic acid-3,4-cyclohexene-1-yl methyl ester and 100.63g TBHP-TBA solution (TBHP mass percent content is 46.05 wt%). Add 3.20g of catalyst molybdenum trioxide (400 mesh), heat up to 90-100°C to start extracting fractions such as by-product tert-butanol, react for 15min, continue to heat up to 100°C-110°C for about 70min and continue to extract by-product tert-butanol Butanol and other fractions were sampled to monitor the reaction progress. After the reaction, a total of 67 g of by-products such as tert-butanol were extracted, the temperature was lowered to 80° C., and 42.11 g of a crude reaction liquid was obtained by filtration.

[0039] Under the vacuum of -0.095MPa, the filtered reaction solution was distilled under reduced pressure at 120°C for 1.5 hours to obtain 28.87g of a colorless and transparent product. The resulting product was detected, and the epoxy equivalent was 130Gm / Eq, and the visco...

Embodiment 2

[0041] 42.00 bis((3,4-cyclohexenyl)methyl)adipate and 100.63g TBHP-TBA solution (the mass percentage of TBHP is 46.05wt%) was added to a 500ml three-necked flask. Add 3.50g catalyst molybdenum trioxide (400 mesh), heat up to 90-100°C and start to extract by-product tert-butanol and other fractions, react for 15min, continue to heat up to 100°C-110°C for about 70min and continue to extract by-product tert-butanol Butanol and other fractions were sampled to monitor the reaction progress. After the reaction, a total of 64.30 g of by-products such as tert-butanol were extracted, the temperature was lowered to 80° C., and 70.11 g of crude reaction liquid was obtained by filtration.

[0042] Under the vacuum of -0.095MPa, the filtered reaction solution was distilled under reduced pressure at 125°C for 1.5 hours to obtain 46.07g of a light yellow product. The resulting product was detected, and the epoxy equivalent was 194Gm / Eq, and the viscosity was 540mPa.s (25 ℃).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com