High-solid-content low-viscosity water-based alkyd emulsion and preparation method thereof

A water-based alkyd technology with high solid content, applied in coatings, anti-corrosion coatings, etc., can solve problems such as low solid content, poor water resistance and anti-corrosion performance, and slow drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1, prepare the alkyd resin A1~A6 of low acid value

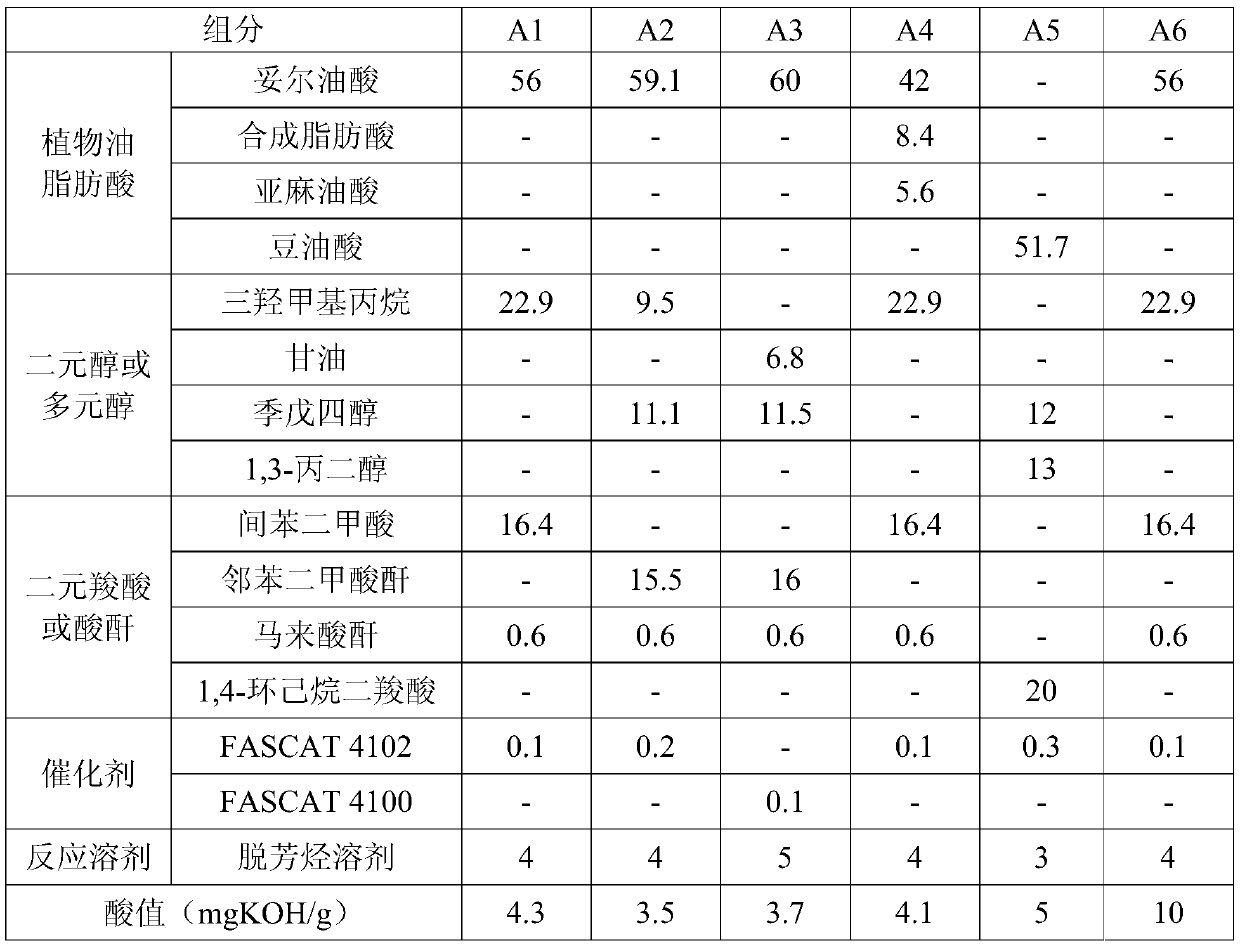

[0088] The formulations and acid values of alkyd resins A1-A6 are listed in Table 1, and the raw materials involved are all commercially available.

[0089] Formulation unit of table 1 alkyd resin A1~A6: parts by weight

[0090]

[0091] The preparation method of alkyd resin A1~A5 is as follows:

[0092] Put the vegetable oil fatty acid, dihydric alcohol or polyol, dicarboxylic acid or anhydride, catalyst and reaction solvent into the reaction kettle in sequence, and gradually raise the temperature to 155±5°C. After the materials melt, start stirring and gradually raise the temperature to 215±5°C, and then keep stirring and reacting in this temperature range until the acid value of the reaction system is less than 5mgKOH / g, that is, alkyd resins A1-A5 with low acid value are obtained.

[0093] The formula and preparation method of alkyd resin A6 are the same as A1, the difference is that the final ac...

Embodiment 2

[0094] Embodiment 2, preparation acrylic modified alkyd resin B1~B7

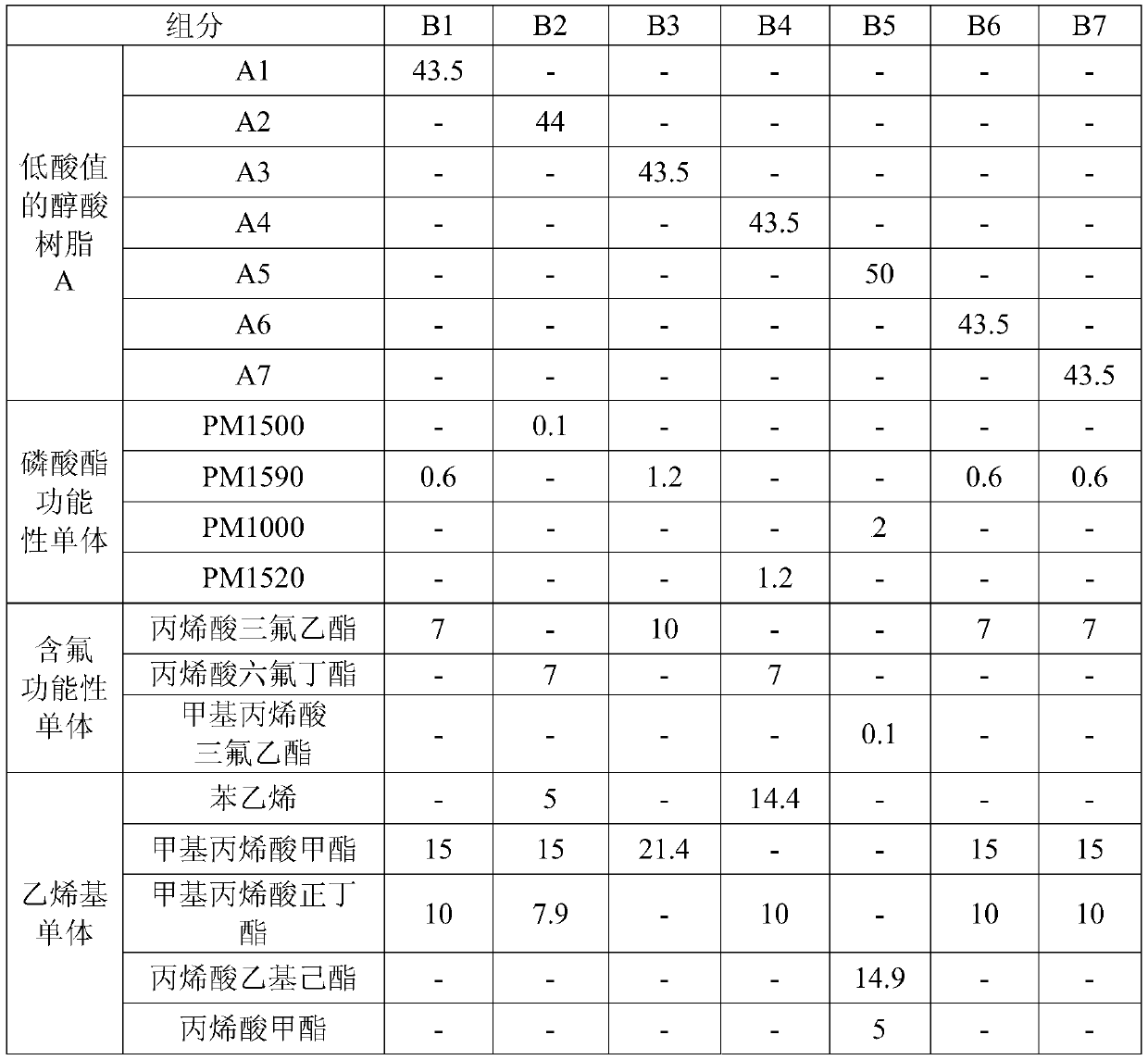

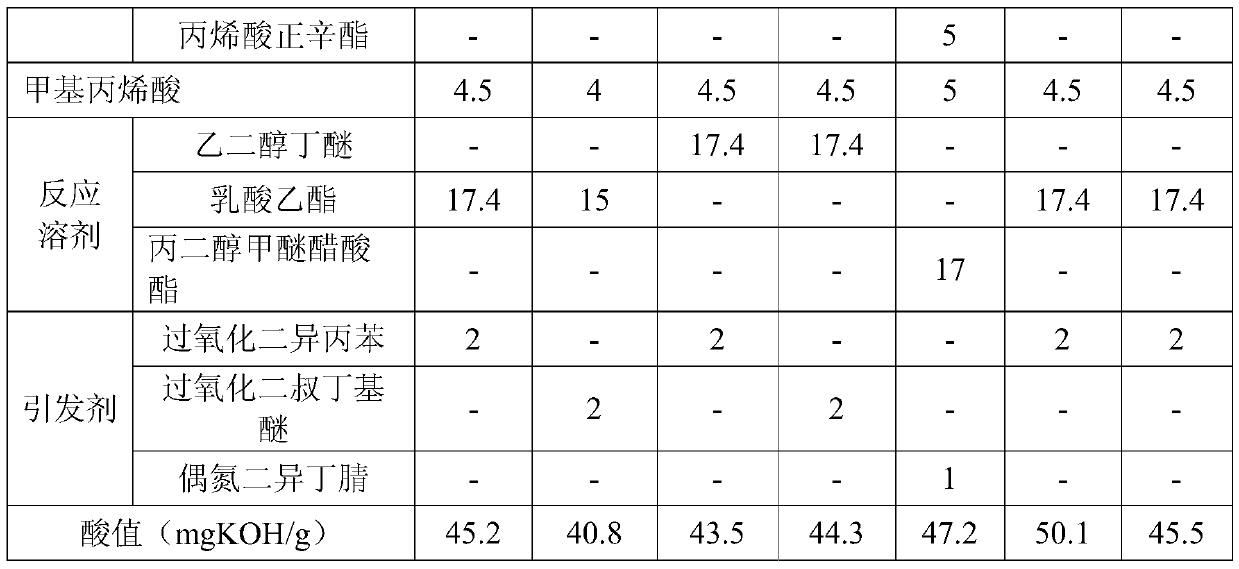

[0095] The formulations of acrylic modified alkyd resins B1-B7 are shown in Table 2. Among them, A7 is a commercially available alkyd resin of the same type, purchased from a synthetic resin company in Guangdong, and its acid value is 4.5 mgKOH / g.

[0096] Table 2 Formula unit of acrylic modified alkyd resins B1-B7: parts by weight

[0097]

[0098]

[0099] The preparation method of acrylic acid modified alkyd resin B1 comprises the steps:

[0100] a) Control the temperature of the alkyd resin A1 with low acid value in the reactor at 155-160°C. According to the formula in Table 2, the phosphate functional monomer, fluorine-containing functional monomer, vinyl monomer, methacrylic acid, 90% of the total weight of the reaction solvent and 60% of the total weight of the initiator are pre-dissolved and mixed uniformly , and then slowly and uniformly drop it into the reaction kettle, drop it in 3 to 4 h...

Embodiment 3

[0107] Example 3, preparation of water-based alkyd emulsions C1-C8

[0108] The formulations and properties of water-based alkyd emulsions C1-C8 are shown in Table 3.

[0109] Table 3 Formulation and performance of water-based alkyd emulsions C1-C8 Unit: parts by weight

[0110]

[0111] The preparation method of water-based alkyd emulsion C1 comprises the steps:

[0112] (1) Adjust the temperature of acrylic modified alkyd resin B1 to 80±5°C, add the formulated amount of neutralizing agent dropwise into the reaction system, and stir for 0.5 hours to make the neutralization uniform; then add deionized solution dropwise Water, dripped in 1.5 ± 0.5 hours, then stirred for 0.5 hours to make it emulsified evenly, and the solid content of the detection system was 44% (weight);

[0113] (2) Control the temperature at 45±5°C. While stirring, add the formulated amount of isocyanate monomer dropwise to the reaction system, drop it within 0.5 hours, keep warm and stir for 1 hour, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com