A kind of high elastic polyester yarn and preparation method thereof

A polyester yarn and high-elasticity technology, which is applied in yarn, melt spinning, rayon manufacturing, etc., can solve the problems of insufficient elastic fabric, tightness and discomfort, poor elasticity of polyester, etc., and achieve increased adhesion and softness Excellent, improved elasticity and wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

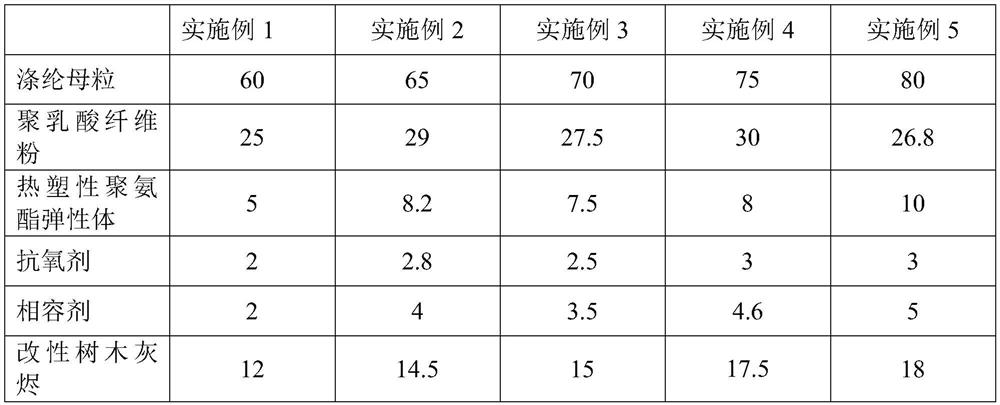

[0051] A high-elastic polyester yarn, its components and parts by mass are shown in Table 1.

[0052] Wherein, the compatibilizer is formed by mixing maleic anhydride grafted EVA and maleic anhydride grafted HDPE according to a mass ratio of 1:0.8.

[0053] Wherein, the tree ashes are modified tree ashes, and the preparation method of the modified tree ashes is as follows:

[0054] Boil tree ashes with 15-20% hydrogen peroxide for 15 minutes, then wash them with distilled water, dry them in an oven at 110°C, add 5 parts by mass of sodium lignosulfonate, 2 parts of polyisobutylene, and 5 parts of The talcum powder was stirred at a high speed in a water bath at 80°C for 2 hours, dried, crushed and ground into superfine powder, and the modified tree ash could be obtained. The mesh number of the modified tree ash was 600 mesh.

[0055] Among them, the talcum powder used to prepare the modified tree ash is modified talcum powder, and the modified talcum powder is prepared by the f...

Embodiment 2

[0066] The difference with embodiment 1 is:

[0067] A high-elastic polyester yarn, its components and parts by mass are shown in Table 1.

[0068] Wherein, the compatibilizer is formed by mixing maleic anhydride grafted EVA and maleic anhydride grafted HDPE according to a mass ratio of 1.5:0.6.

[0069] Wherein, the tree ashes are modified tree ashes, and the preparation method of the modified tree ashes is as follows:

[0070] Boil tree ashes with 15-20% hydrogen peroxide for 18 minutes, then wash them with distilled water, dry them in an oven at 115°C, add 6.5 parts of sodium lignosulfonate, 2.5 parts of polyisobutylene, 6 parts of The talc powder was stirred in a water bath at 85°C for 2.5 hours at high speed, dried, crushed and ground into superfine powder, and the modified tree ash could be obtained. The mesh number of the modified tree ash was 800 mesh.

[0071] Among them, the talcum powder used to prepare modified tree ash is modified talcum powder, and the modified...

Embodiment 3

[0082] The difference with embodiment 1 is:

[0083] A high-elastic polyester yarn, its components and parts by mass are shown in Table 1.

[0084] Wherein, the compatibilizer is formed by mixing maleic anhydride grafted EVA and maleic anhydride grafted HDPE according to a mass ratio of 2:1.2.

[0085] Wherein, the tree ashes are modified tree ashes, and the preparation method of the modified tree ashes is as follows:

[0086] Boil tree ashes with 20% hydrogen peroxide for 20 minutes, then wash them with distilled water, dry them in an oven at 120°C, add 8 parts by mass of sodium lignosulfonate, 3 parts of polyisobutylene, and 7 parts of talcum powder , stirred at high speed in a water bath at 90°C for 3 hours, dried, crushed and ground into superfine powder to obtain the modified tree ash, and the mesh number of the modified tree ash is 1000 mesh.

[0087] Among them, the talcum powder used to prepare the modified tree ash is modified talcum powder, and the modified talcum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com