Method for predicting initiation location or expansion direction of cracks on metal surface

A technology of propagation direction and metal surface, applied in the field of predicting the crack initiation position or propagation direction of metal surface, which can solve the limited testing accuracy and experimental conditions of DIC equipment, cannot accurately characterize the behavior of small deformation in micro-area, and predict crack initiation and propagation. behavior and other issues, to achieve the effect of strong operability, wide range of use and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

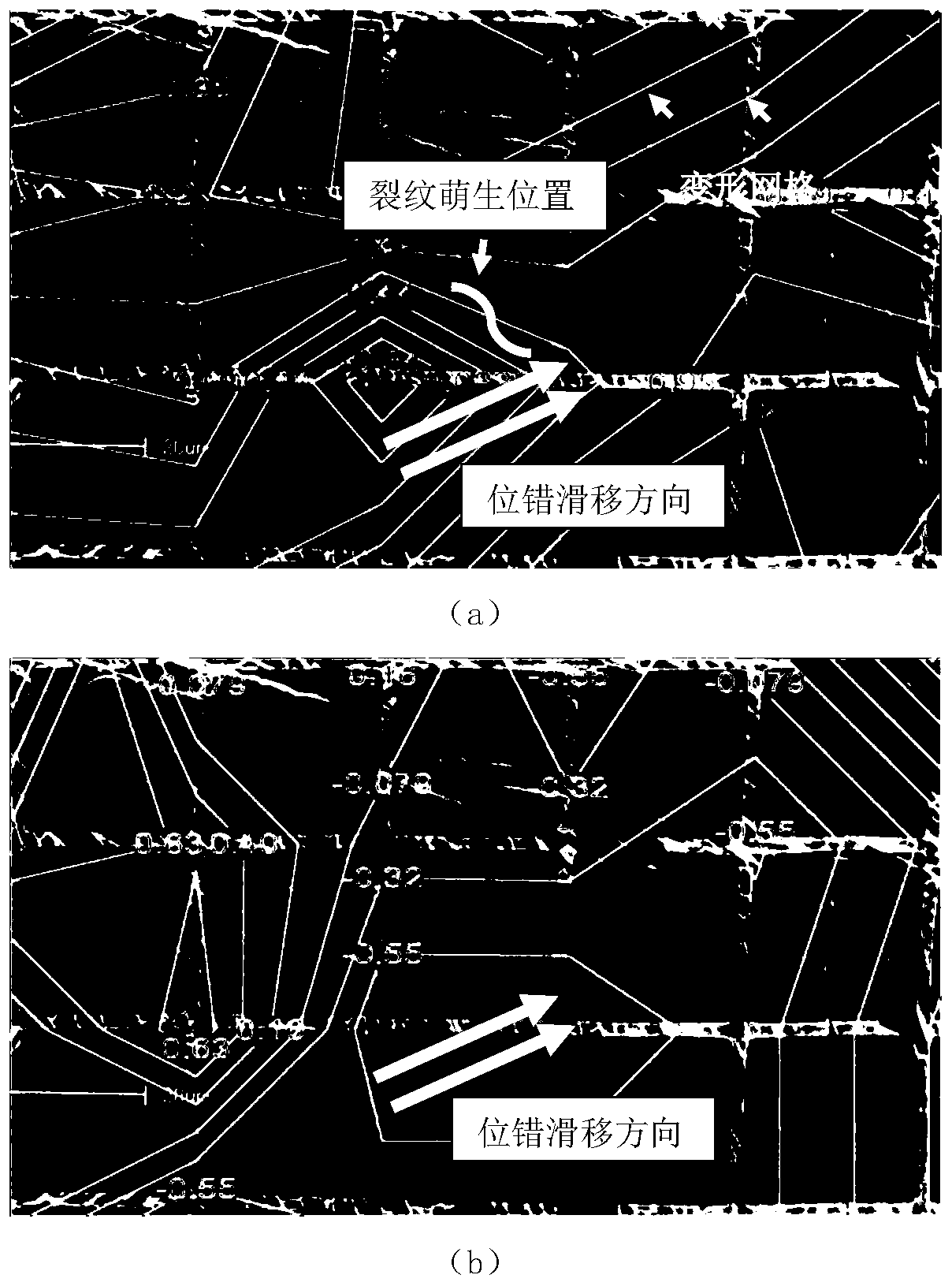

[0043] A method of predicting the location of crack initiation or the direction of propagation on a metal surface, such as figure 1 , 2 shown, prepared by the following steps:

[0044] 1) The cast titanium alloy fatigue crack growth sample is prepared by machining method, the surface of the sample is polished and corroded to show the microstructure morphology, cleaned with alcohol and then dried;

[0045] 2) Uniformly coat a layer of photoresist with a thickness of 0.5 μm on the surface of the titanium alloy by using the glue-spinning method (the rotation speed is 800 rpm), and then dry it. Cover the mask plate (single grid side length 20 μm) on the photoresist, use a photolithography machine to expose the mask plate and photoresist on the surface of the material for 60 seconds and then develop, forming a grid morphology on the surface of the titanium alloy;

[0046] 3) Put the titanium alloy in 2) in the electron beam evaporator, the parameters are: the vacuum degree of the e...

Embodiment 2

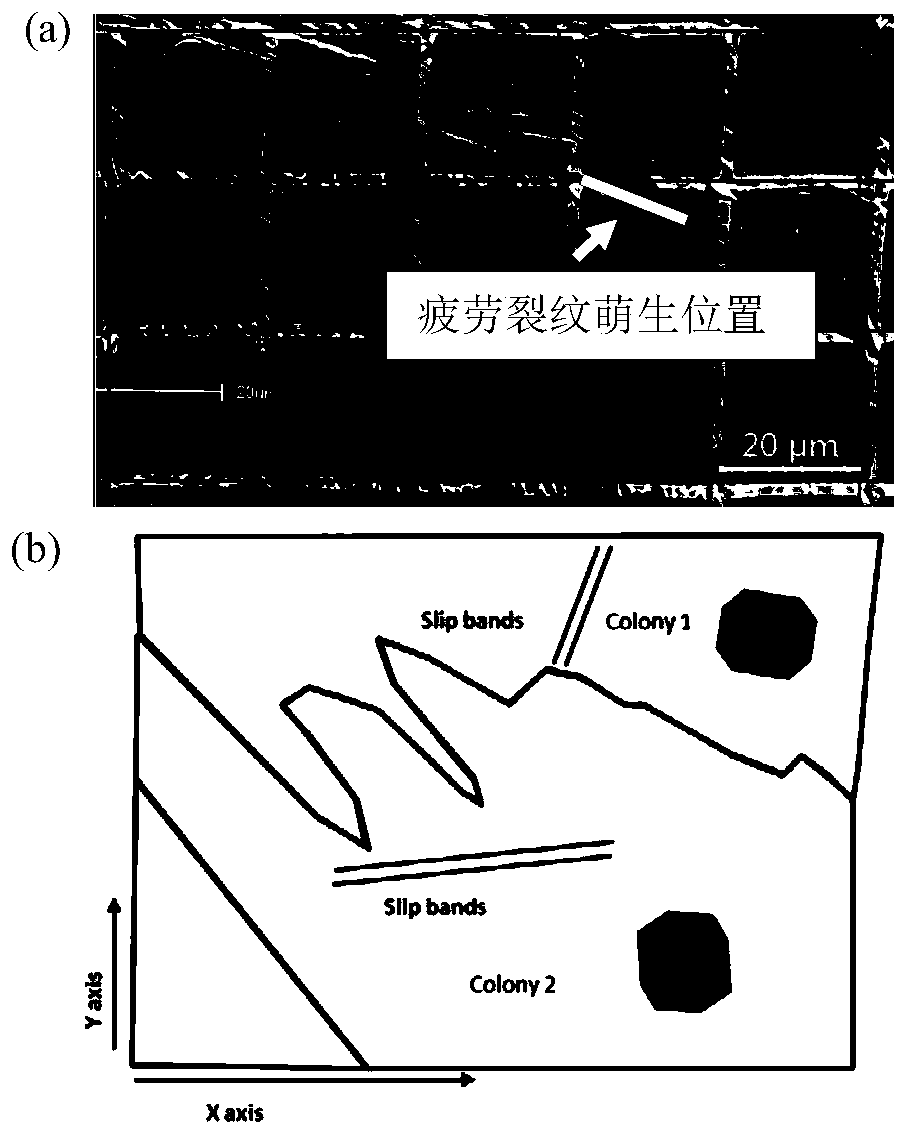

[0052] A method for predicting the micro-area fatigue crack initiation position of titanium alloy is obtained by measuring the grid deformation of titanium alloy surface micro-area, combined with the description of structure morphology, crystal orientation and slip line characteristics. Contains the following steps:

[0053] 1) Prepare the cast titanium alloy fatigue sample by machining method, polish and corrode the surface of the sample to show the microstructure morphology, clean it with alcohol and dry it;

[0054] 2) Uniformly coat a layer of photoresist with a thickness of 50 μm on the surface of the titanium alloy by using the glue-spinning method (3000 rpm), and then dry it. Cover the mask plate (single grid side length 20 μm) on the photoresist, use a photolithography machine to expose the mask plate and photoresist on the surface of the material for 600s and then develop, forming a grid morphology on the surface of the titanium alloy;

[0055] 3) Put the titanium al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com