Copper-based nano-catalyst as well as preparation method and application thereof

A nano-catalyst, copper-based technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of long-distance targets, poor stability, low catalyst activity, etc., to achieve catalytic performance improvement, preparation Simple process and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

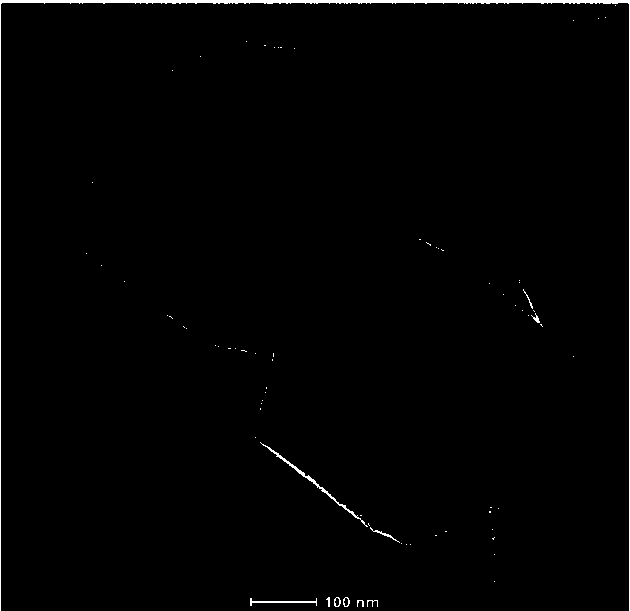

[0029] The preparation method of the copper-based nano-catalyst provided by a typical embodiment of the present invention comprises the following steps:

[0030] Step 1, 2-methylimidazole and methanol are mixed and then stirred to form a homogeneous solution A.

[0031] In step 2, zinc nitrate hexahydrate, copper acetylacetonate and an organic solvent are mixed and then stirred to form a uniform solution B. Preferably, the organic solvent is methanol. The mass ratio of 2-methylimidazole, zinc nitrate hexahydrate, and copper acetylacetonate is preferably 1.314:1.190:(0.21-1.05), more preferably 1.314:1.190:0.628.

[0032] Step 3: Add solution A to solution B and stir thoroughly, then transfer the stirred solution to a polytetrafluoroethylene liner and place it in a blast drying oven for hydrothermal treatment. Preferably, the temperature of the hydrothermal treatment is 90-180 degrees centigrade for 1-24 hours.

[0033] In step 4, the product obtained in step 3 is centrifuge...

Embodiment 1

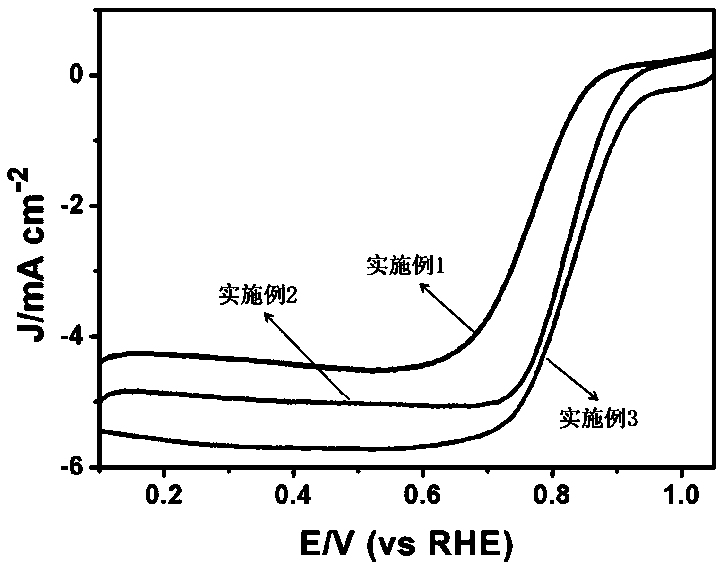

[0041] Add 2-methylimidazole (1.314 g) and methanol (15 mL) into flask A and stir with a magnetic stirrer to form a homogeneous solution A; add zinc nitrate hexahydrate (1.190 g) and copper acetylacetonate (0.628 g) into flask B and methanol (30 mL) with a magnetic stirrer to form a homogeneous solution B; slowly pour the solution A in the above flask A into the flask B, stir with a magnetic stirrer for 1 h, and then transfer the stirred solution into polytetrafluoroethylene The lining was placed in a blast drying oven for hydrothermal treatment at 120 °C for 4 h. The resulting product was centrifuged with methanol in a high-speed centrifuge, and the centrifuged product was placed in a vacuum drying oven at 60°C for 8 h; the vacuum-dried product was placed in a magnetic boat and kept at 800°C for 3 h under an argon atmosphere to form Subsequent treatment can directly use the copper-based nano-catalyst with catalytic performance. Applying it to the electrocatalytic oxygen redu...

Embodiment 2

[0043] Add 2-methylimidazole (1.314 g) and methanol (15 mL) into flask A and stir with a magnetic stirrer to form a homogeneous solution A; add zinc nitrate hexahydrate (1.190 g) and copper acetylacetonate (0.628 g) into flask B and methanol (30 mL) with a magnetic stirrer to form a homogeneous solution B; slowly pour the solution A in the above flask A into the flask B, stir with a magnetic stirrer for 1 h, and then transfer the stirred solution into polytetrafluoroethylene The lining was placed in a blast drying oven for hydrothermal treatment at 120 °C for 4 h. The resulting product was centrifuged with methanol at 8000 rpm for 5 minutes in a high-speed centrifuge, and the centrifuged product was placed in a vacuum drying oven at 60 degrees Celsius for 8 h; Raise the temperature to 900 degrees Celsius and keep it for 3 hours to form a copper-based nanocatalyst that can be used directly without subsequent treatment and has catalytic performance. Applying it to the electroca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting current density | aaaaa | aaaaa |

| Limiting current density | aaaaa | aaaaa |

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com