Preparation method of silicone rubber with high thermal conductivity

A silicone rubber, high thermal conductivity technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problem that the thermal conductivity of silicone rubber is not high, cannot meet the requirements of electrical insulation, and cannot meet the thermal conductivity of thermal conductive materials for high-power electronic equipment. requirements and other issues to achieve the effect of improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

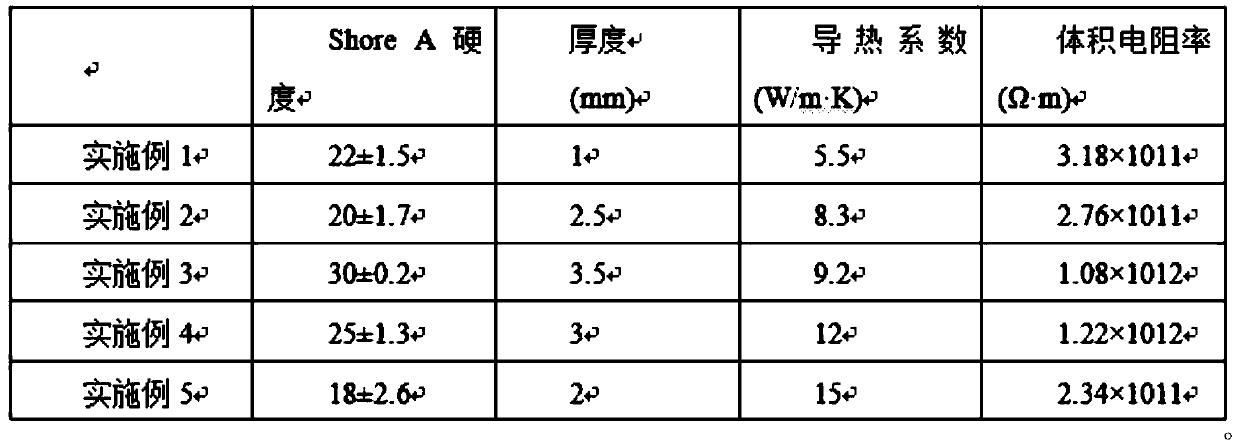

Examples

preparation example Construction

[0036] The invention provides a preparation method of high thermal conductivity silicone rubber. The technical solution of the present invention is described in detail below to make it easier to understand and grasp.

[0037] The preparation method of high thermal conductivity silicon rubber comprises the steps:

[0038] Material selection, choose graphite, thermally conductive filler, silicone rubber substrate, silicone oil, catalyst, inhibitor and crosslinking agent.

[0039] Planetary ball milling, solid-phase mixing of graphite and thermally conductive fillers, and obtaining graphene-wrapped fillers after planetary ball milling. The planetary ball milling time is 30-240min, and the milling speed is 100-600r / min.

[0040] Ultrasonic treatment, the graphene-wrapped filler is subjected to ultrasonic treatment to obtain a treated thermally conductive filler. The ultrasonic power is 300W, and the ultrasonic treatment time is 30-120min.

[0041] Mixing, put the graphene-wrap...

Embodiment 1

[0055] Select the following components and parts by mass, natural graphite graphene (1 μm in particle size): 0.5 parts; methyl vinyl silicone rubber: 80 parts; spherical alumina (75 μm in particle size): 70 parts; hydrogen-containing silicone oil (containing The amount of hydrogen accounts for 0.06% of the total weight of hydrogen-containing silicone oil): 1.0 parts; platinum catalyst: 0.05 parts; diphenylsilanediol: 0.01 parts; Oxy)hexane: 0.1 part.

[0056] First, 75 μm spherical alumina powder and natural graphite graphene (1 μm particle size) were solid-phase mixed by planetary ball milling to obtain graphene-coated thermally conductive fillers. The ball milling speed was 100 r / min, and the ball milling time was 200 min. Secondly, the graphene-coated thermally conductive filler was added to the methyl vinyl silicone rubber, and treated under ultrasonic for 80 min, and the ultrasonic power was 300W. Then, the silicone rubber premix containing thermally conductive filler, h...

Embodiment 2

[0058] Select the following components and parts by mass, natural graphite (thickness is 70mm): 0.64 parts, methyl phenyl silicone rubber: 75 parts, boron nitride and zinc oxide: 75 parts, hydrogen-containing silicone oil (hydrogen content accounts for 0.1% of the total weight of hydrogen silicone oil): 1.0 parts, platinum catalyst: 1.0 parts, methylphenyldiethoxysilane: 0.02 parts; 2,4-dichlorobenzoyl peroxide: 0.2 parts.

[0059] First, a mixture of boron nitride and zinc oxide was mixed with natural graphite (70 mm in thickness) in a solid state by planetary ball milling to obtain graphene-coated thermally conductive fillers. The ball milling speed was 250 r / min, and the ball milling time was 100 min. Secondly, add the graphene-coated thermally conductive filler into the methylphenyl silicone rubber, and treat it under ultrasonic for 60min, and the ultrasonic power is 300W. Then, the silicone rubber premix containing thermally conductive filler, hydrogen-containing silicone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com