Biosynthesis method of dendritic glucosyl nanoparticles

A nanoparticle, glucosyl technology, applied in the field of biosynthesis of dendritic glucosyl nanoparticles, can solve the problem of few research reports on glucosyl nanoparticle polymers, difficulty in controlling the degree of polymerization and branching, and random structure etc. to achieve the effects of low cost, easy operation, and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

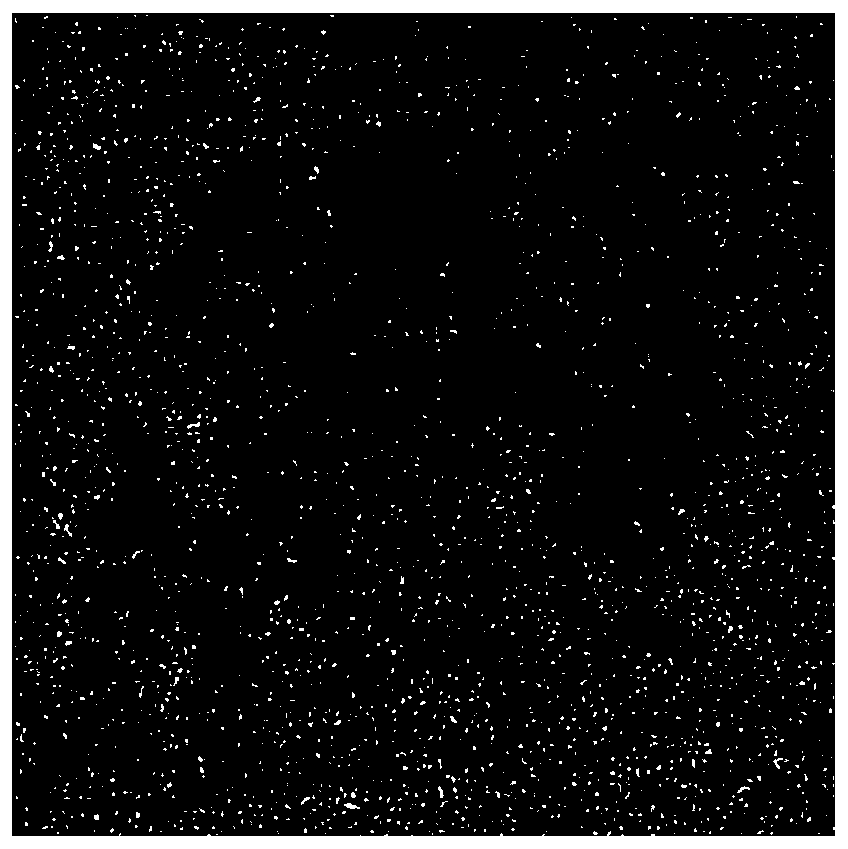

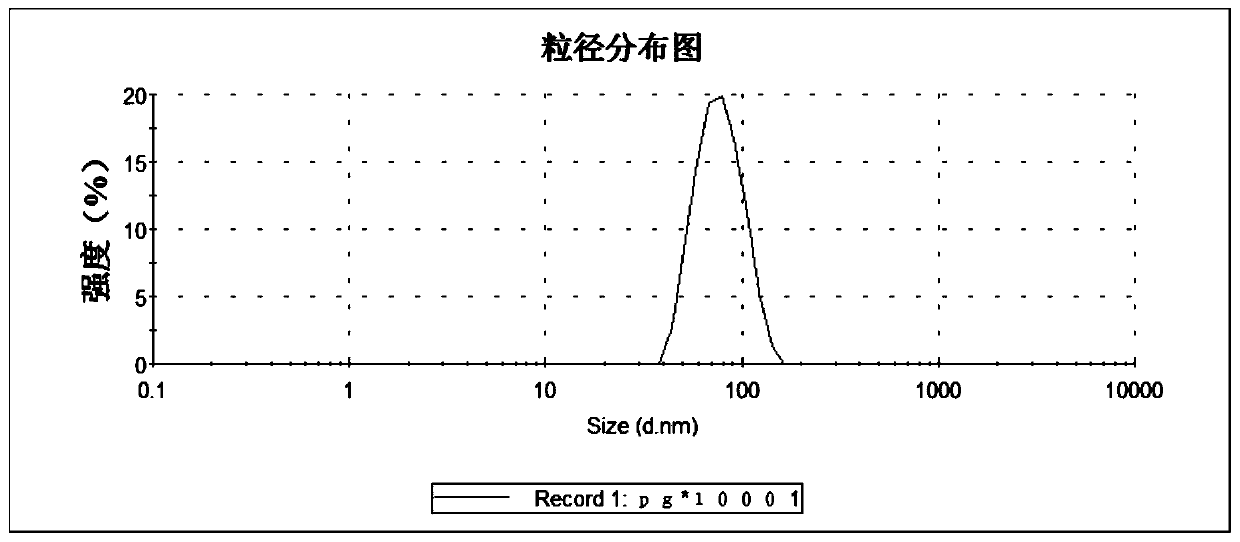

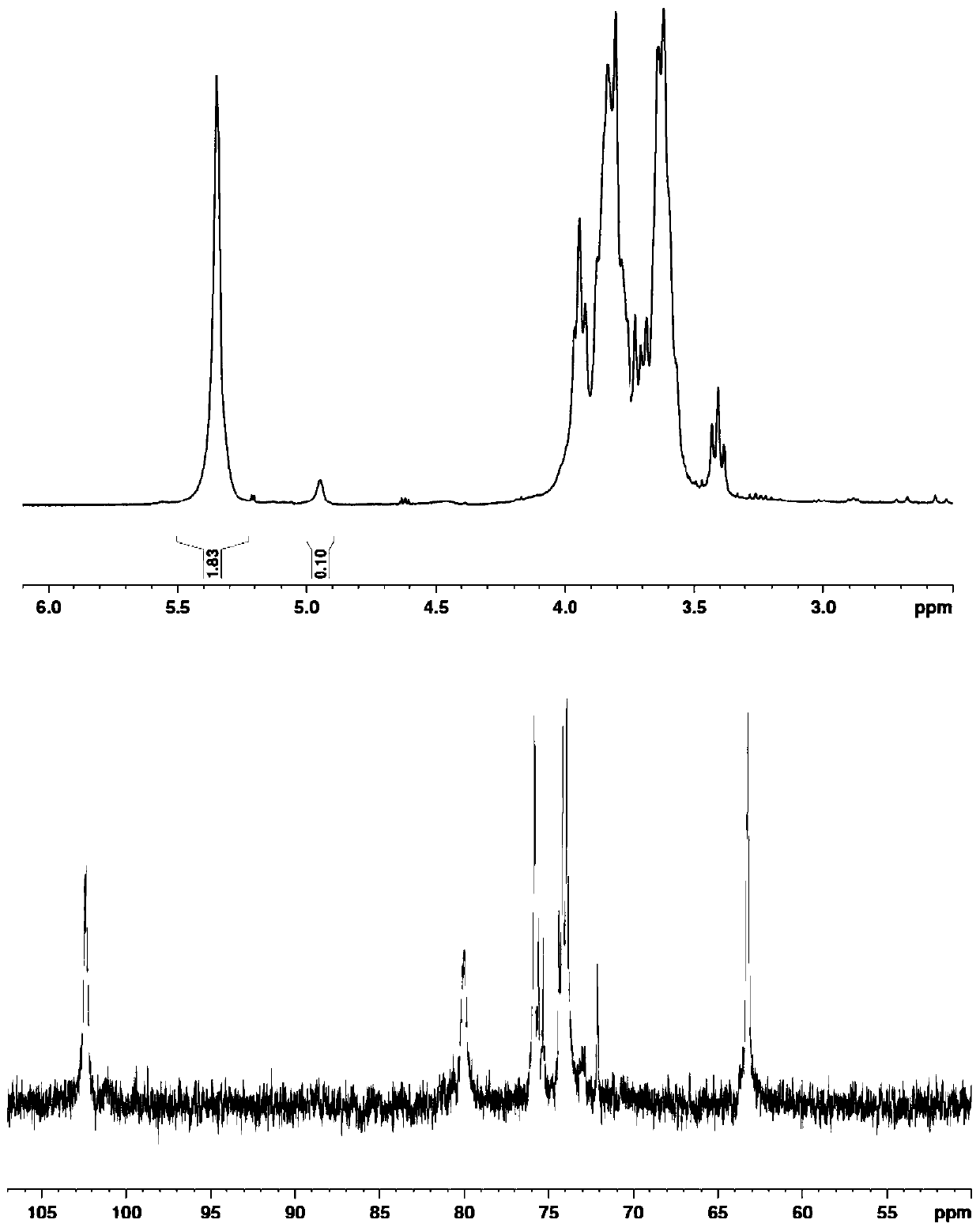

[0029] Weigh 10g of β-cyclodextrin and dissolve it in 1000mL of phosphate buffer (pH 7.0), place it in a water bath at 70°C for 30 minutes, and then add 100U of in vitro polysaccharase preparation (new pullulanase: 1 of the carbohydrase family 13, 4-α-glucan branching enzyme = 1:1) react at constant temperature for 6 hours, heat inactivate the enzyme after the reaction, centrifuge, and vacuum-dry the supernatant to obtain the target product. Dendritic glucosyl nanoparticles have an average size of 35nm and an absolute molecular weight of 4.2×10 6 g / mol, polydispersity coefficient 1.0, branch density 7.3%.

Embodiment 2

[0031] Weigh 10g macrocyclodextrin and dissolve it in 50mL phosphate buffer (pH 7.0), place it in a 70°C water bath for 30 minutes, and then add 200U in vitro polysaccharide enzyme preparation (cyclomatodextrinase: 1 of the carbohydrase family 13 , 4-α-glucan branching enzyme = 10:1) constant temperature reaction for 24 hours, after the reaction was completed, the enzyme was inactivated by heating, centrifuged, and the obtained supernatant was vacuum-dried to obtain the target product. Dendritic glucosyl nanoparticles have an average size of 78nm and an absolute molecular weight of 1.9×10 7 g / mol, polydispersity coefficient 1.2, branch density 6.7%.

Embodiment 3

[0033] Weigh 10 g of γ-cyclodextrin and dissolve it in 250 mL of phosphate buffer (pH 7.0), place it in a water bath at 70°C for 30 min, and then add 50 U of in vitro polysaccharide enzyme preparation (maltose glucosylase: 1 of the carbohydrase family 57, 4-α-glucan branching enzyme = 1:10) constant temperature reaction for 2 hours, heat inactivation and centrifugation after the reaction, and vacuum-dry the obtained supernatant to obtain the target product. Dendritic glucosyl nanoparticles have an average size of 41nm and an absolute molecular weight of 8.9×10 5 g / mol, polydispersity coefficient 1.1, branch density 6.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Absolute molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com