A kind of low fibroin scaffold and preparation method thereof

A protein scaffold and silk protein technology, which is applied in the field of biomedicine, can solve the problems of inability to prepare low-crystallinity water-insoluble silk protein scaffolds, etc., and achieves the effects of good hot water stability, mild conditions and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

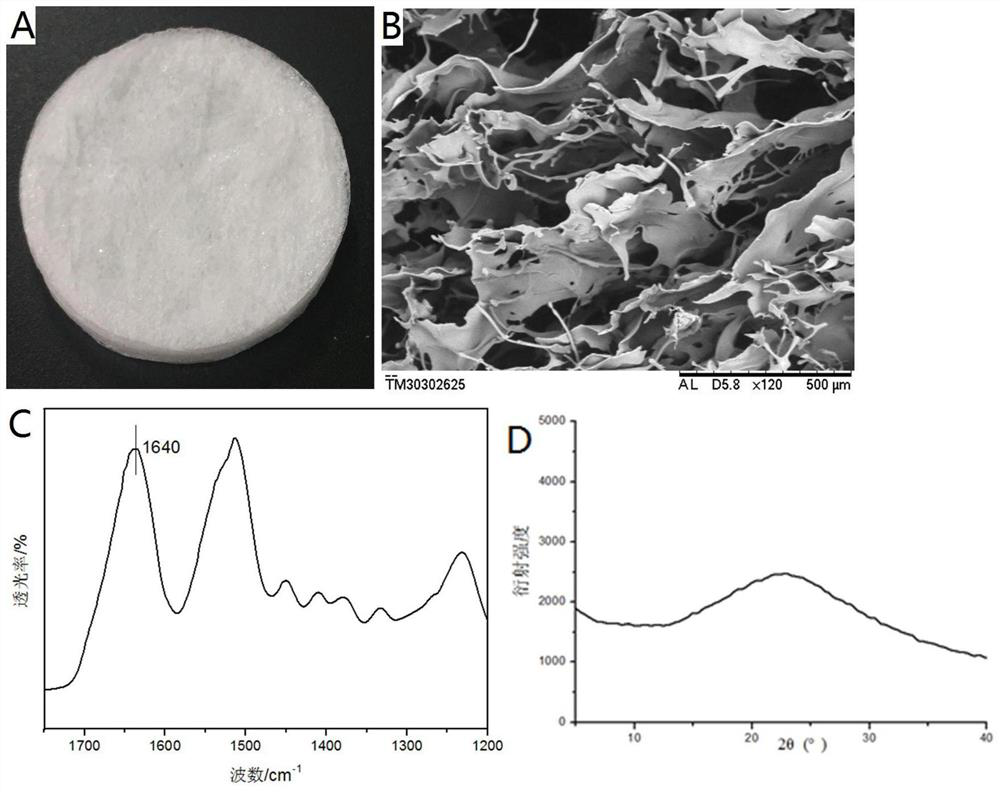

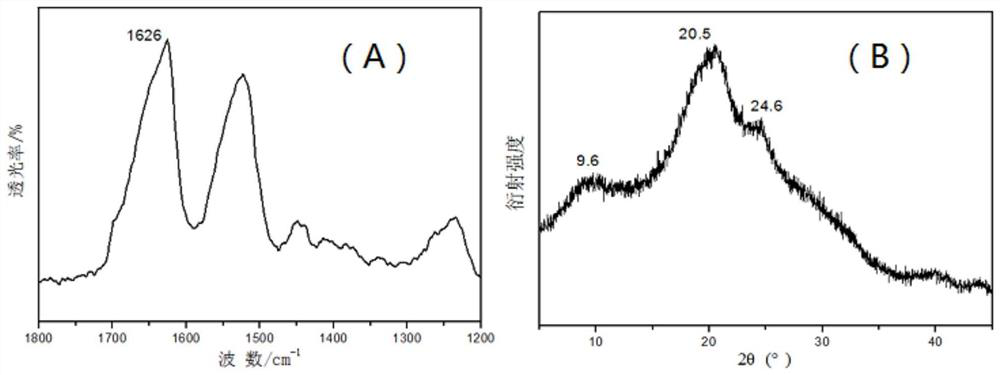

Image

Examples

Embodiment 1

[0035] Soak about 10g raw silk in 0.5L 0.5% Na 2 CO 3 solution, stirred and boiled for 60 minutes, then removed and washed with deionized water. After repeating the above operation twice, the silk was dried at 60°C.

[0036] 5 g of the degummed silk after the above treatment was weighed and dissolved in 30 mL of LiBr solution with a concentration of 9.8 mol / L, stirred and dissolved at 60° C. for one hour. Then use a dialysis bag with a molecular weight cut off of 3500 to dialyze with deionized water for 3 days to obtain a silk protein aqueous solution with a concentration of 6%, and further adjust the concentration of the silk protein aqueous solution to 2%.

[0037] Take 10 mL of the above silk protein solution, add 5 mL of 0.5% ethylene glycol solution, stir evenly, pour it into a polyethylene mold, and then put the mold containing the mixed solution into -20 ° C for 6 hours to freeze. Then take out the frozen body, put it into deionized water to thaw for 1 hour, then rin...

Embodiment 2

[0040] Soak about 50g raw silk in 2L 0.05% Na 2 CO 3 solution, stirred and boiled for 60 minutes, then removed and washed with deionized water. After repeating the above operation twice, the silk was dried at 60°C.

[0041] 15 g of the degummed silk after the above treatment was weighed and dissolved in 100 mL of LiBr solution with a concentration of 9.8 mol / L, stirred and dissolved at 60° C. for one hour. Then use a dialysis bag with a molecular weight cut-off of 3500 to dialyze with deionized water for four days to obtain a silk protein aqueous solution with a concentration of 7%, and adjust the concentration of the silk protein aqueous solution to 4%.

[0042] Take 15 mL of the above silk protein solution, blend it with 15 mL of ethanol with a mass fraction of 0.1%, and then pour it into a polyethylene mold and freeze it at -20°C for 10 hours. After being frozen, it was taken out, thawed in the air at natural temperature for 2 hours, rinsed with deionized water for 3 hou...

Embodiment 3

[0045] Soak about 50g raw silk in 2L 0.05% Na 2 CO 3 solution, stirred and boiled for 60 minutes, then removed and washed with deionized water. After repeating the above operation twice, the silk was dried at 60°C.

[0046] 15 g of the degummed silk after the above treatment was weighed and dissolved in 100 mL of LiBr solution with a concentration of 9.8 mol / L, stirred and dissolved at 60° C. for one hour. Then use a dialysis bag with a molecular weight cut-off of 3500 to dialyze with deionized water for four days to obtain a silk protein aqueous solution with a concentration of 7%, and adjust the concentration of the silk protein aqueous solution to 5%.

[0047] Take 15 mL of the above silk protein solution, blend it with 30 mL of methanol with a mass fraction of 0.01%, and then pour it into a polyethylene mold and freeze it at -20°C for 12 hours. After being frozen, it was taken out, thawed in the air at natural temperature for 1 hour, rinsed with deionized water for 3 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com