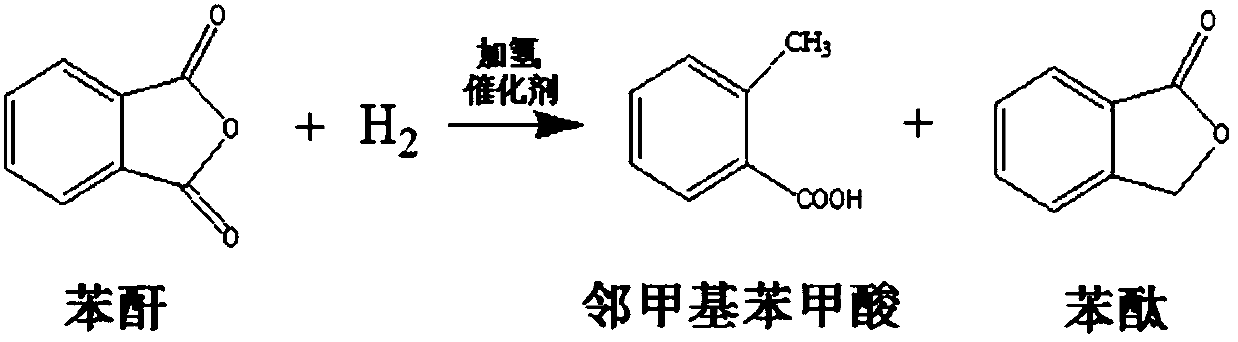

Method for preparing o-toluic acid and phthalide from phthalic anhydride

A technology of o-toluic acid and phthalic anhydride, which is applied in the field of chemical product preparation to achieve the effects of mild reaction conditions, broad requirements, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Preparation of hydrogenation catalyst

[0056] Prepare a solution of 8.3g of nickel nitrate and 12.5g of pure water, weigh 10g of 60-80 mesh alumina particles, impregnate the two in equal volume for 12 hours, dry them continuously at 80°C, and then place them in a muffle furnace Roast at 450°C for 3 hours, then slowly drop to room temperature; prepare a solution with 0.13g of cerium nitrate and 0.13g of ruthenium nitrate and 12.5g of pure water, and soak the same volume with the above-mentioned roasted product in a 40°C thermostat for 12 hours again. After the secondary impregnation is completed, dry it at 80°C, put it into a muffle furnace and bake it at 450°C for 2 hours, and take it out after cooling down to room temperature for later use.

[0057] The catalyst needs to be activated by hydrogen before it can be used again. The activation uses an ordinary tube furnace. Put the weighed catalyst into it and pass in hydrogen. When the temperature reaches 380°C, start...

Embodiment 2

[0063] (1) Preparation of hydrogenation catalyst

[0064] Prepare a solution of 8.3g of nickel nitrate and 12.5g of pure water, weigh 10g of 60-80 mesh alumina particles, impregnate the two in equal volume, put them in a 40°C ultrasonic box for 2 hours, and then take them out at room temperature The environment was left to stand for 4 hours. After impregnation, continue to dry at 80°C, then bake in a muffle furnace at 450°C for 3 hours, and slowly drop to room temperature; prepare a solution with 0.13g of cerium nitrate and 0.13g of ruthenium nitrate and 12.5g of pure water, and mix with The above-mentioned roasted product was impregnated again in an equal volume at 40°C for 12 hours. After the second impregnation was completed, it was dried at 80°C, then put into a muffle furnace and roasted at 450°C for 2 hours, and then cooled to room temperature. Take out and set aside.

[0065] The catalyst needs to be activated by hydrogen before it can be used again. The activation us...

Embodiment 3

[0071] (1) Preparation of hydrogenation catalyst

[0072] Prepare a solution of 8.3g of nickel nitrate and 12.5g of pure water, weigh 10g of 60-80 mesh alumina particles, impregnate the two in equal volume, put them in a 40°C ultrasonic box for 2 hours, and then take them out at room temperature The environment was left to stand for 4 hours. After impregnation, continue to dry at 80°C, then bake in a muffle furnace at 450°C for 3 hours, and slowly drop to room temperature; prepare a solution with 0.13g of cerium nitrate and 0.13g of ruthenium nitrate and 12.5g of pure water, and mix with The above-mentioned roasted product was impregnated again in an equal volume at 40°C for 12 hours. After the second impregnation was completed, it was dried at 80°C, then put into a muffle furnace and roasted at 450°C for 2 hours, and then cooled to room temperature. Take out and set aside.

[0073] The catalyst needs to be activated by hydrogen before it can be used again. The activation us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com