A method for extracting lithium in spodumene, an adsorption material for extraction thereof, and a preparation method thereof

A technology of adsorption materials and extraction methods, applied in chemical instruments and methods, other chemical processes, lithium carbonate;/acid carbonate, etc., can solve the problems of large consumption of acid and alkali, poor extraction effect, etc. Long service life, good extraction effect, and the effect of ensuring extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

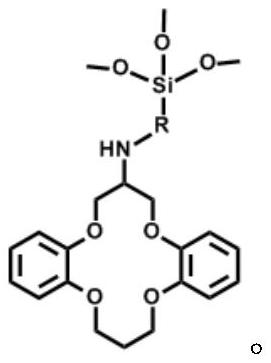

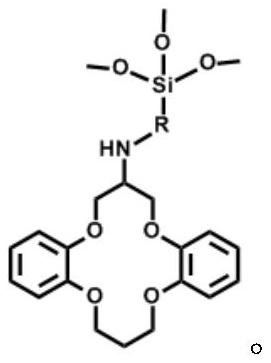

[0042] The preparation method of adsorption material of the present invention specifically comprises the following steps:

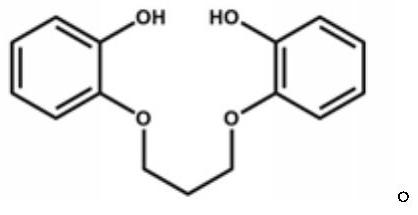

[0043] (1) React 1,3-dibromopropane, catechol and NaOH at a molar ratio of 1:(2-3):(2-3), preferably a molar ratio of 1:2:2. Specifically, first add 1,3-dibromopropane and catechol into the reaction flask, stir and heat up to 120-140°C, add NaOH aqueous solution within 1-2h and stir for 5-10h; Pour the liquid into 5N NaOH aqueous solution, add an appropriate amount of CH 2 Cl 2 , filter to remove solid impurities, adjust the filtrate to be neutral with HCl solution, and then use CH 2 Cl 2 Extraction, anhydrous Na 2 SO 4 Dry, remove the solvent with a rotary evaporator, and pass through the column with silica gel powder to obtain product A, and the structural formula of product A is as follows:

[0044]

[0045] (2) React the product A, LiOH and epichlorohydrin at a molar ratio of 1:(2-3):(1-2), preferably a molar ratio of 1:2:1. Specifically, un...

Embodiment 1

[0062] The preparation process of the adsorbent material of the present embodiment is as follows:

[0063] (1) React 1,3-dibromopropane, catechol and NaOH at a molar ratio of 1:2:2. Specifically, first add 1,3-dibromopropane and catechol into the reaction flask, stir and heat up to 120°C, add NaOH aqueous solution within 1h and stir for 5h; then pour the reaction mixture into 5N NaOH In the aqueous solution, add an appropriate amount of CH 2 Cl 2 , filter to remove solid impurities, adjust the filtrate to be neutral with HCl solution, and then use CH 2 Cl 2 Extraction, anhydrous Na 2 SO 4 Dry, remove the solvent with a rotary evaporator, and pass through a column with silica gel powder to obtain product A.

[0064] (2) The product A, LiOH and epichlorohydrin were reacted in a molar ratio of 1:2:1. Specifically, under the protection of nitrogen, the product A, LiOH, H 2 Add O into the reaction flask, heat up to 90°C and stir until completely dissolved; cool down to 40°C...

Embodiment 2

[0074] The preparation process of the adsorbent material of the present embodiment is as follows:

[0075] (1) 1,3-dibromopropane, catechol and NaOH were reacted at a molar ratio of 1:2.5:2.5. Specifically, first add 1,3-dibromopropane and catechol into the reaction flask, stir and heat up to 125°C, add NaOH aqueous solution within 1.5h and stir for 6h; then pour the reaction mixture into 5N NaOH aqueous solution, add an appropriate amount of CH 2 Cl 2 , filter to remove solid impurities, adjust the filtrate to be neutral with HCl, then use CH 2 Cl 2 Extraction, anhydrous Na 2 SO 4 Dry, remove the solvent with a rotary evaporator, and pass through a column with silica gel powder to obtain product A.

[0076] (2) The product A, LiOH and epichlorohydrin were reacted in a molar ratio of 1:2.5:1.5. Specifically, under the protection of nitrogen, the product A, LiOH, H 2 Add O into the reaction flask, heat up to 92°C and stir until completely dissolved; drop the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com