Heat-resistant hydroxypropyl-terminated PDMS room-temperature rapid self-repairing elastomer and preparation method and use thereof

A hydroxypropyl sealing, elastomer technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, coatings, etc., can solve the research reports of rapid self-healing at room temperature that have not yet been flexible and heat-resistant materials. The demand for aerospace heat-resistant materials, without considering the heat-resistant properties of materials, etc., achieves the effects of a wide range of use, long service life and high repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

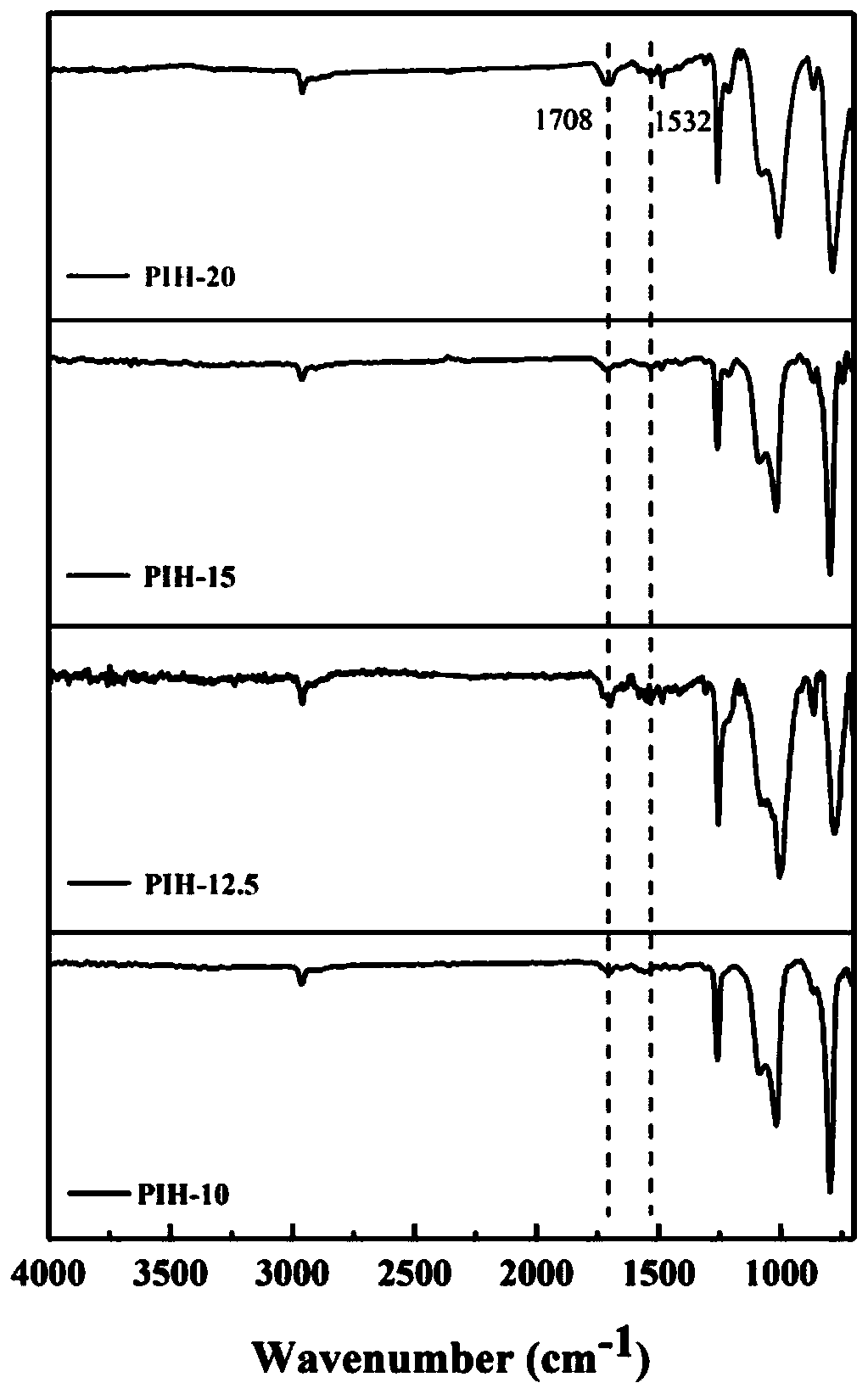

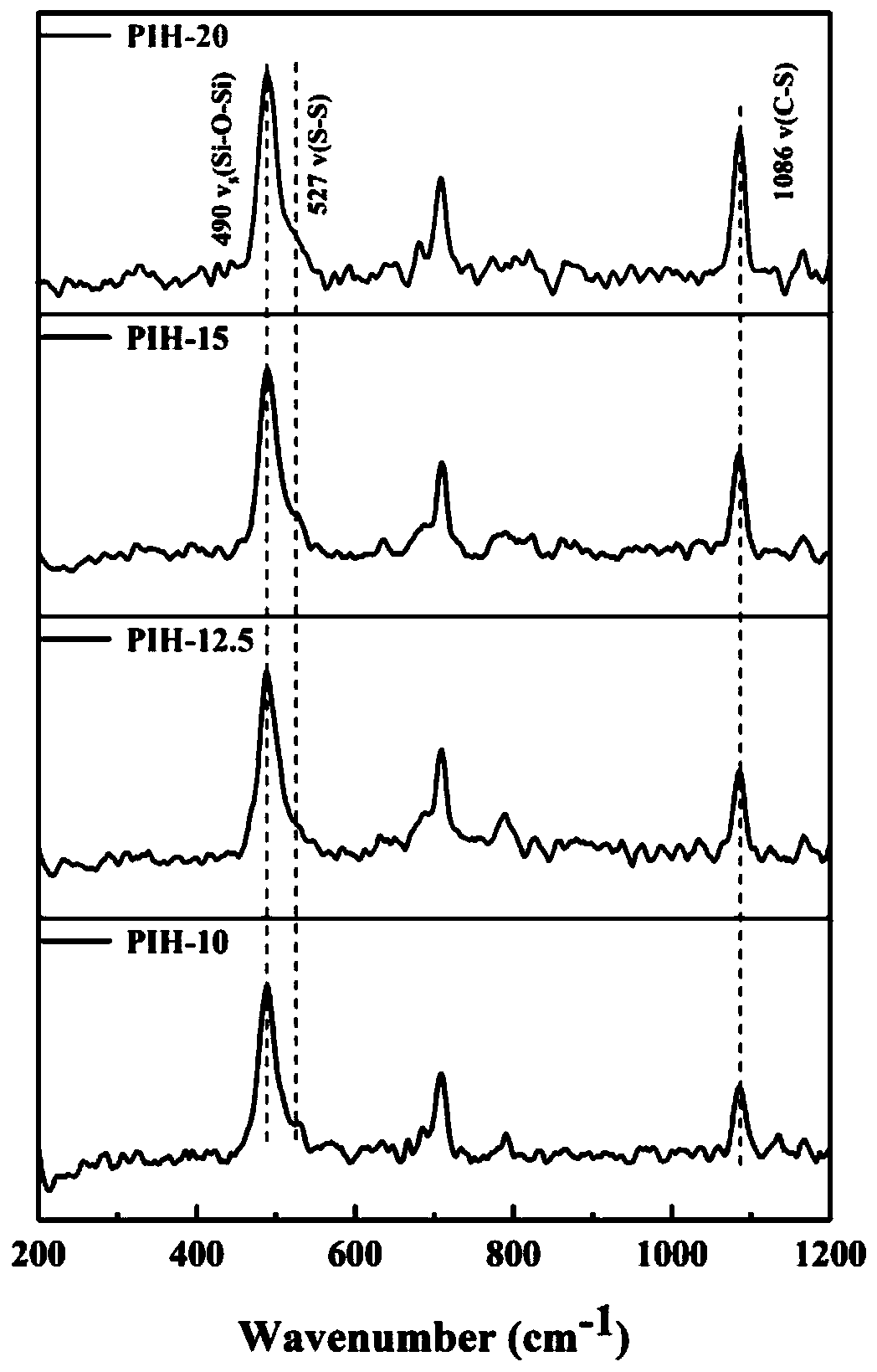

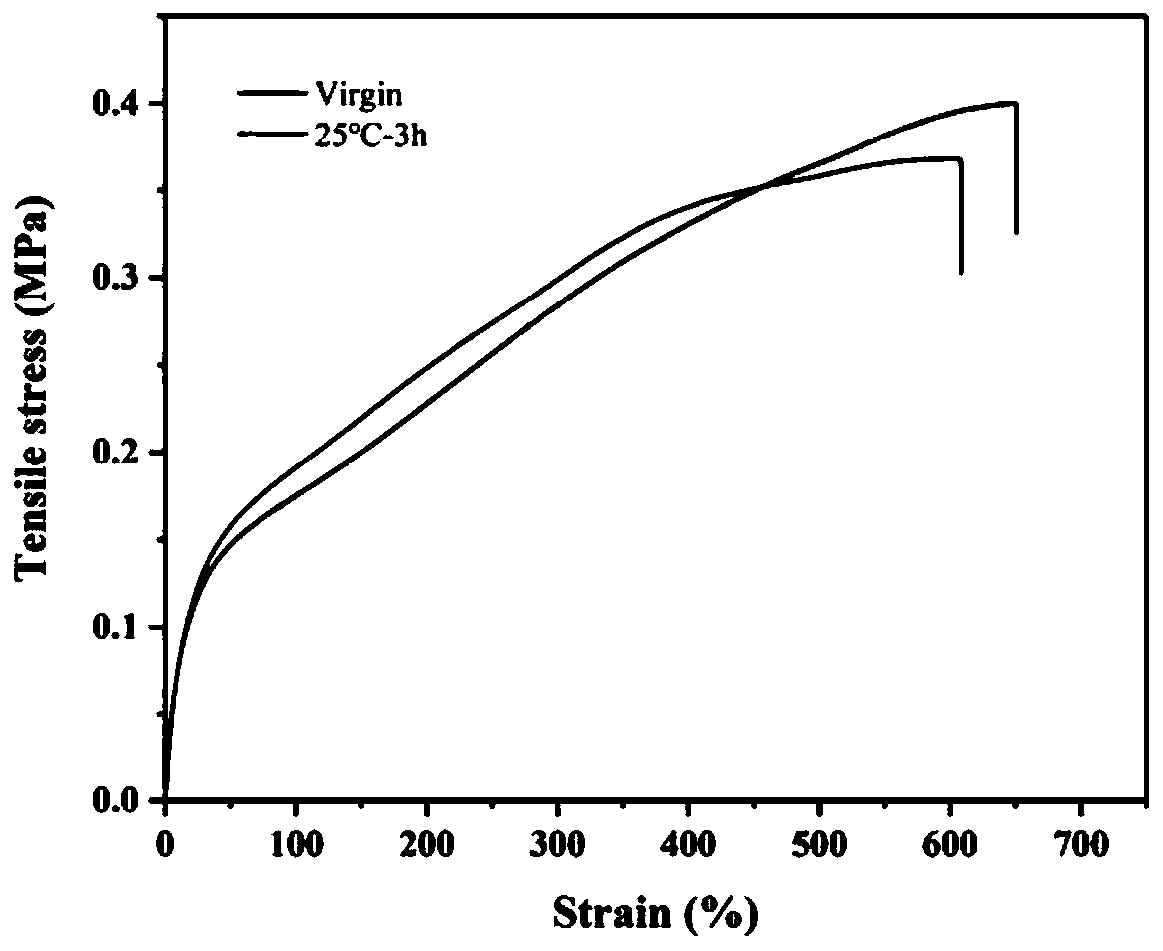

[0043]Embodiment 1, the preparation of self-healing elastomer of the present invention

[0044] (1) Synthesis of prepolymer: pour 10mmol of hydroxypropyl-terminated polydimethylsiloxane (HO-PDMS-OH, molecular weight 2000-4000) and 21mmol of isophorone diisocyanate (IPDI) Put it into a flask, add 3000ppm catalyst dibutyltin dilaurate (DBTDL), stir at 80°C with argon for 3 hours, and cool to room temperature to obtain a prepolymer.

[0045] (2) Chain extension reaction: Dissolve 10mmol 4,4'-dihydroxydiphenyl disulfide (HPDS) as a chain extender in 2mL dimethylacetamide, and add dropwise to the prepolymer prepared in step (1) , reacted at 60° C. for 2 h, and added dimethylacetamide after the reaction was completed to prepare the reaction solution into a reaction solution in which the polymer concentration obtained by the chain extension reaction was 30%.

[0046] (3) Pour the reaction solution into a polytetrafluoroethylene mold, keep a vacuum at 90°C for 12h, and remove the res...

Embodiment 2

[0047] Embodiment 2, the preparation of self-healing elastomer of the present invention

[0048] (1) Synthesis of prepolymer: 10mmol of hydroxypropyl-terminated polydimethylsiloxane (HO-PDMS-OH, molecular weight 2000-4000) and 23.625mmol of isophorone diisocyanate (IPDI) Pour it into a flask, add 3000ppm catalyst dibutyltin dilaurate (DBTDL), stir with argon at 80°C for 3 hours, and cool to room temperature to obtain a prepolymer.

[0049] (2) Chain extension reaction: Dissolve 12.5 mmol 4,4'-dihydroxydiphenyl disulfide (HPDS) as a chain extender in 2 mL of dimethylacetamide, and add dropwise to the prepolymer prepared in step (1) The mixture was reacted at 60° C. for 2 hours. After the reaction was completed, dimethylacetamide was added to prepare the reaction solution into a reaction solution with a polymer concentration of 30% obtained by the chain extension reaction.

[0050] (3) Pour the reaction solution into a polytetrafluoroethylene mold, keep a vacuum at 90°C for 12h...

Embodiment 3

[0051] Embodiment 3, the preparation of self-healing elastomer of the present invention

[0052] (1) Synthesis of prepolymer: 10mmol of hydroxypropyl-terminated polydimethylsiloxane (HO-PDMS-OH, molecular weight 2000-4000) and 26.25mmol of isophorone diisocyanate (IPDI) Pour it into a flask, add 3000ppm catalyst dibutyltin dilaurate (DBTDL), stir with argon at 80°C for 3 hours, and cool to room temperature to obtain a prepolymer.

[0053] (2) Chain extension reaction: Dissolve 15mmol 4,4'-dihydroxydiphenyl disulfide (HPDS) as a chain extender in 2mL dimethylacetamide, and add dropwise to the prepolymer prepared in step (1) , reacted at 60° C. for 2 h, and added dimethylacetamide after the reaction was completed to prepare the reaction solution into a reaction solution in which the polymer concentration obtained by the chain extension reaction was 30%.

[0054] (3) Pour the reaction solution into a polytetrafluoroethylene mold, keep a vacuum at 90°C for 12h, and remove the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com