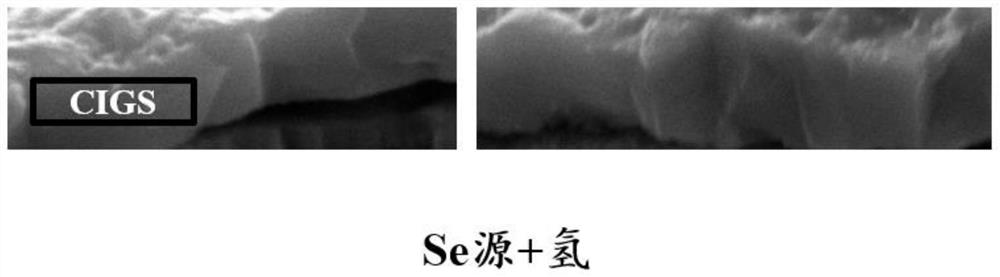

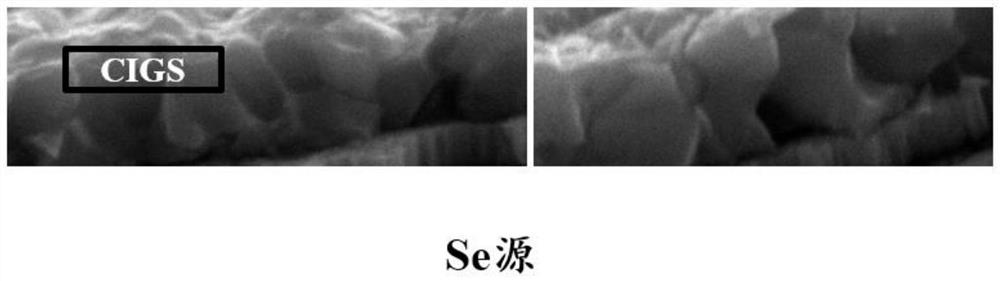

A system for hydrogenation of selenium source in flexible cigs solar cells to enhance selenium reactivity

A solar cell, reactive technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of battery failure, flammability and explosion, high risk, etc., to improve film quality, improve reactivity, improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

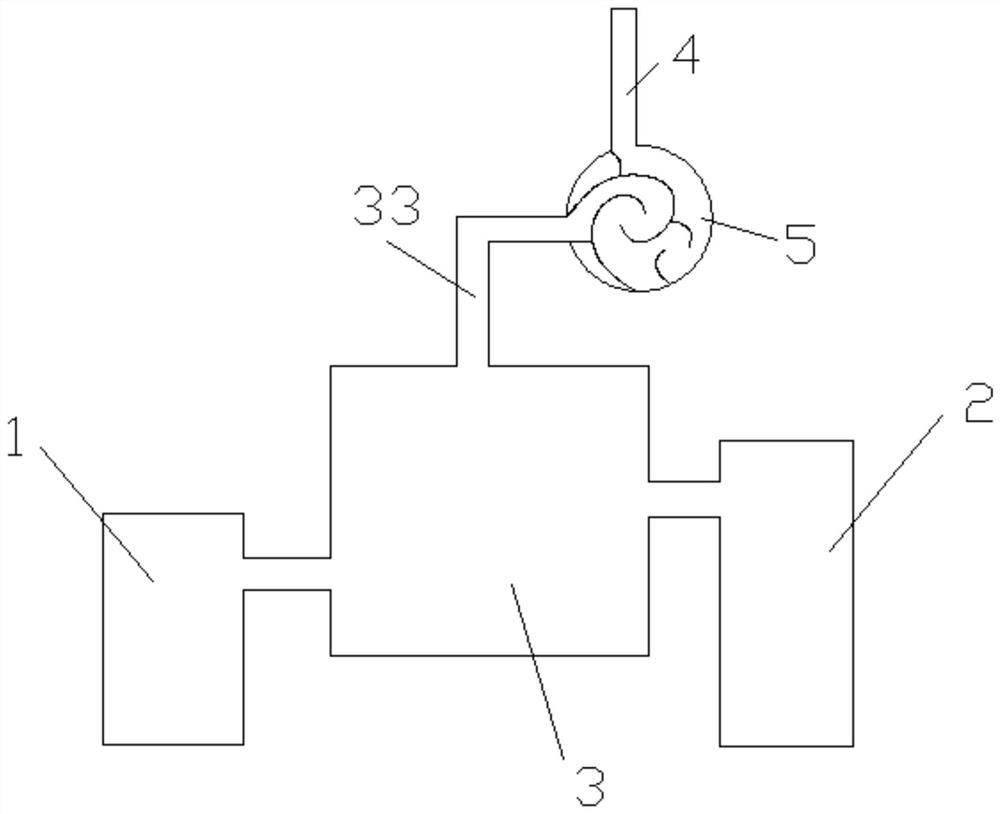

[0037] Such as image 3 , Figure 4 A system for hydrogenation of selenium sources of flexible CIGS solar cells to enhance selenium reactivity is shown, comprising a selenium source 1, a hydrogen storage tank 2, an automatic gas mixing device 3 and a mixed gas output pipeline 4, and the automatic gas mixing device includes Selenium vapor control valve 31, hydrogen control valve 32 and gas delivery pipeline 33, the selenium vapor outlet of the selenium source is connected to the inlet 34 of the selenium vapor control valve, the hydrogen gas outlet of the hydrogen storage tank is connected to the inlet 35 of the hydrogen gas control valve, and the selenium vapor control valve is connected to the inlet 35 of the selenium vapor control valve The outlet is connected to the selenium vapor inlet of the gas delivery pipeline, the outlet of the hydrogen control valve is connected to the hydrogen inlet of the gas delivery pipeline, the outlet of the gas delivery pipeline is connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com