Process method for in-situ upgrading and capacity expansion of municipal sewage

A technology of municipal sewage and process method, which is applied in the field of in-situ standardization and expansion of municipal sewage, which can solve the problems of inability to obtain the required land, low sludge volume, small biomass, etc., and achieve the expansion of sewage treatment capacity and sludge discharge Effect of reducing and reducing sludge load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

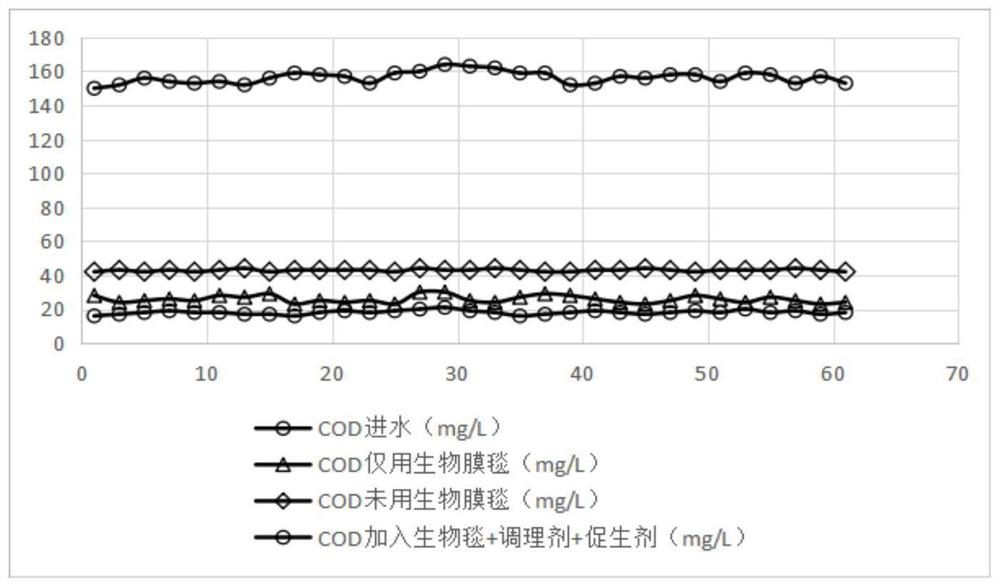

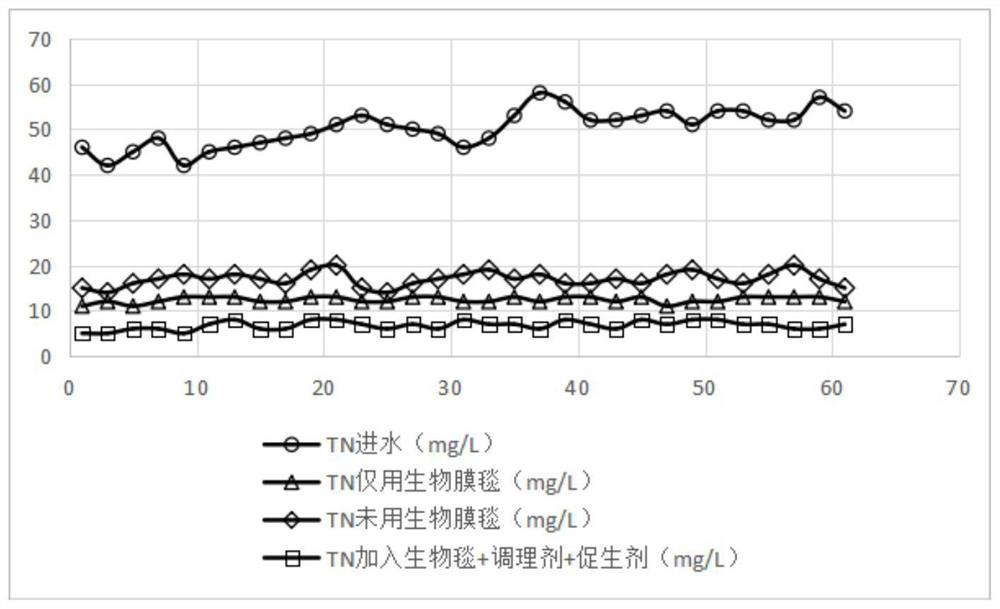

[0040] Case 1: Only use biofilm blanket

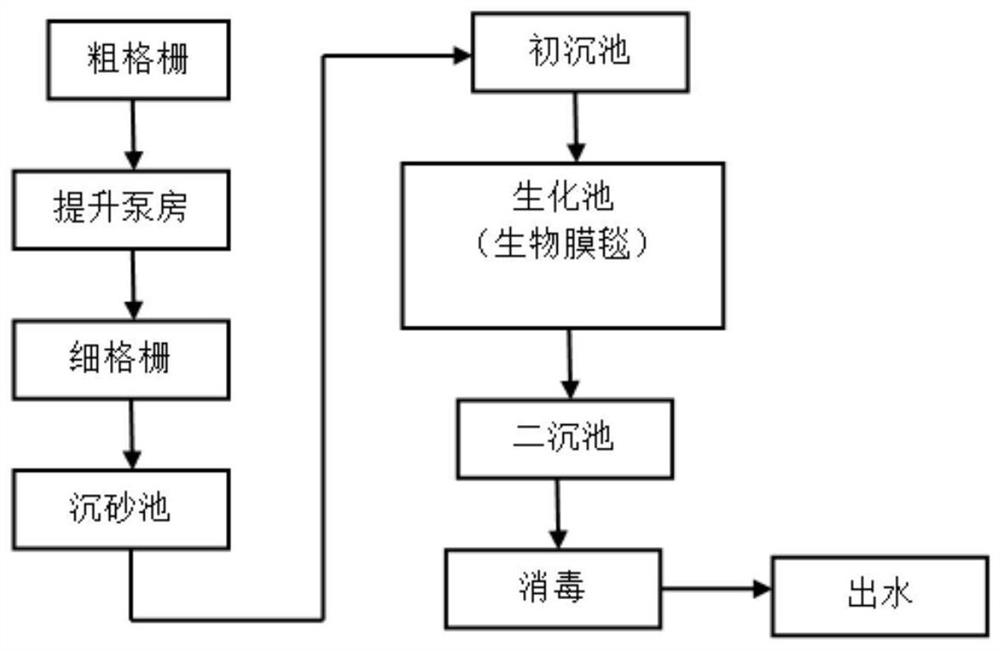

[0041] in the original A 2 Based on the O sewage treatment process, the original A 2 O The main process of sewage treatment is water inflow → grille → anaerobic pond → anoxic pond → aerobic pond → sedimentation pond → effluent, in the original A 2 O Sewage treatment aerobic pool Add biofilm blanket device for sewage treatment, the biofilm blanket device for sewage treatment is the biofilm blanket device for sewage treatment disclosed by the patent No. ZL201922130741.2, including the following steps:

[0042] (1) The bottom supporting installation of the biofilm blanket device, fix the two ends of the supporting steel structure on the inner wall of the aerobic tank at 1500mm above the aerator at the bottom of the aerobic biochemical tank, and then fix the two ends of the supporting steel structure on the upper end surface of the supporting steel structure Place the fiberglass grille on it.

[0043] (2) The polyurethane biofilm modifi...

Embodiment 2

[0062] Case 1: Only use biofilm blanket

[0063] Transformation is carried out on the basis of the original SBR sewage treatment process. The main process of the original SBR sewage treatment is water intake→grid→anaerobic tank→regulation tank→SBR reaction tank→sedimentation disinfection tank→water outlet. In the original SBR sewage A biofilm blanket device for sewage treatment is added to the SBR reaction tank. The biofilm blanket device for sewage treatment is a biofilm blanket device for sewage treatment disclosed in the patent No. ZL201922130741.2, which includes the following steps:

[0064] (1) The upper part of the biofilm device is fixedly installed: the polyurethane biofilm of the same inorganic ion doping modification as Example 1 is placed on the FRP grid as a biofilm blanket, and then the two ends of the supporting steel structure top are fixed on On the upper edge of the SBR reaction tank, the upper part is fixed and installed with a biofilm blanket device for sew...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com