Method for preparing ethylene glycol by photocatalytic methanol dehydrogenation coupling

A dehydrocoupling and ethylene glycol technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, organic compounds, etc., can solve problems such as poor selectivity of ethylene glycol, easy deactivation of catalysts, ZnS photocorrosion, etc. Achieve the effects of promoting performance, high product selectivity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

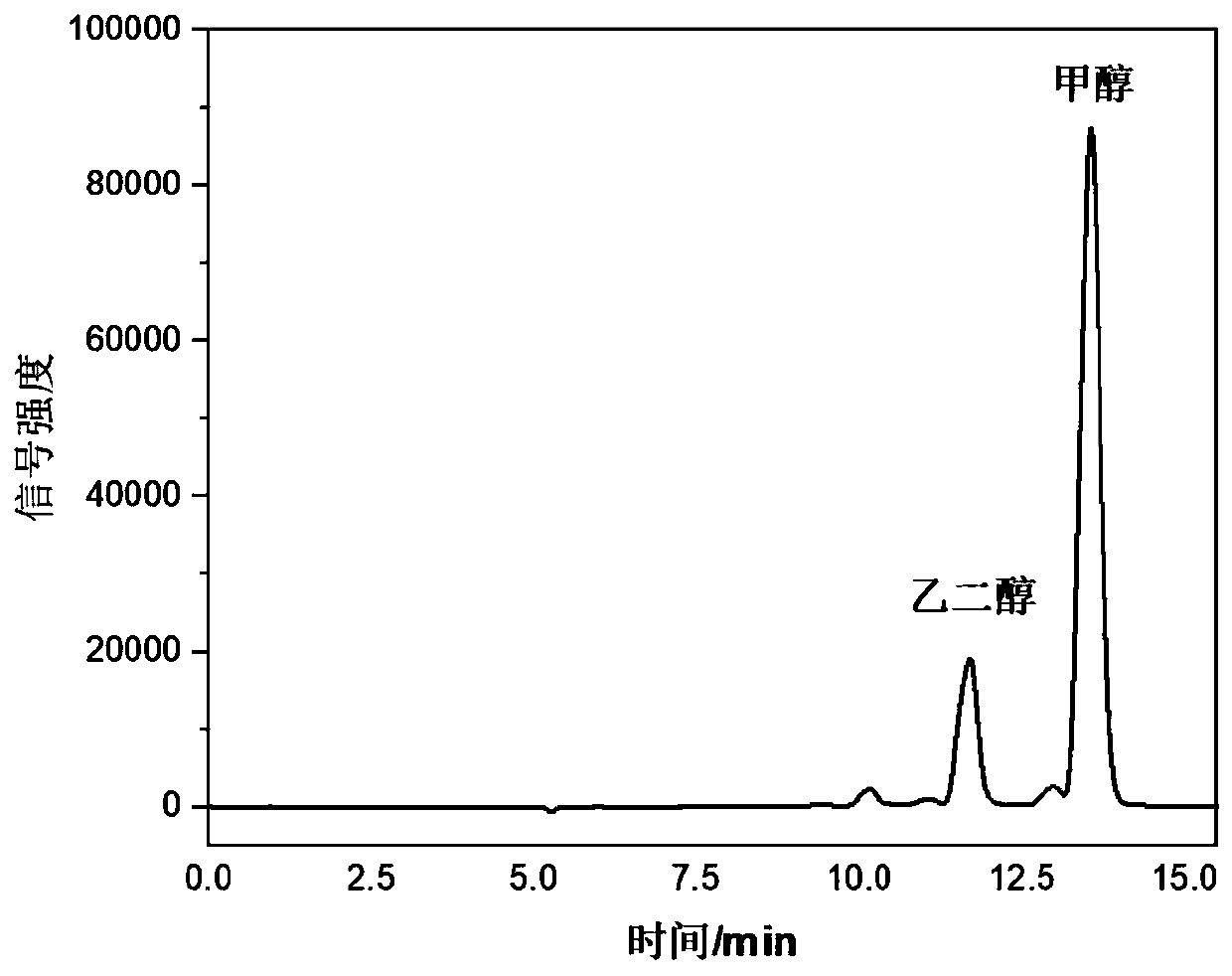

Embodiment 1

[0034] 20mmol of CdCl2 2.5H 2 O and 60 mmol of CH 4 N 2 S was added to 60 mL of anhydrous ethylenediamine, stirred thoroughly for 30 min, and then the solution was transferred to a 200 mL autoclave and kept at 150 °C for 12 h to obtain CdS nanorods. CdS nanorods were centrifuged and washed 3 times, placed in an oven at 60°C for 12 hours, dried for later use, dried and ground to obtain CdS solid powder, and 1% Co was photodeposited onto CdS nanorods to obtain a photocatalyst. Take 10 mg of the above photocatalyst and 300 mg of (trifluoromethyl)benzene, add them into 5 mL of methanol solvent, turn on a 300 W xenon lamp, and carry out photocatalytic reaction under visible light conditions for 12 h. After the reaction solution was filtered, liquid chromatography analysis showed that the generation rate of ethylene glycol was 23.3mmol g cat -1 h -1 , the selectivity of ethylene glycol is 90%.

[0035] Such as figure 1 Shown is the transmission electron microscope image of th...

Embodiment 2

[0037] 10mmol of Cd(CH 3 COO) 2 and 10mmol of Zn(CH 3 COO) 2 Add to 40mL deionized water, add ethylenediamine and thioacetamide, then add water to 60mL, transfer the above solution into a 100mL autoclave, heat to 230°C for 12h to obtain Zn 0.5 Cd 0.5 S nanorods, washed by centrifugation several times after cooling, dried for 12 h, and photodeposited 1% Mn to Zn 0.5 Cd 0.5 S, that is, the photocatalyst is prepared. Take 10 mg of the above photocatalyst and add it to 5 mL of methanol aqueous solution, add 100 mg of benzene, turn on a 300 W mercury lamp, and carry out photocatalytic reaction under visible light conditions for 4 hours. After the reaction solution was filtered, liquid chromatography analysis showed that the generation rate of ethylene glycol was 32mmol g cat -1 h -1 , the selectivity of ethylene glycol is 90%.

Embodiment 3

[0039] 3mmol Zn(CH 3 COO) 2 and 3mmol InCl 3 Add to 250mL deionized water respectively, then add thioacetamide, heat the above solution to 95°C and keep stirring for 5h to obtain Zn 2 In 2 S 5 . Ultrasonic washing and centrifugal drying, photodeposition of 1% Co to Zn 2 In 2 S 5 On, the photocatalyst is prepared. Take 10 mg of the above photocatalyst and add it to 5 mL of methanol solvent, add 100 mg of toluene, turn on a 300 W xenon lamp, and carry out photocatalytic reaction under ultraviolet light for 12 hours. After the reaction solution was filtered, liquid chromatography analysis showed that the generation rate of ethylene glycol was 15mmol g cat -1 h -1 , the selectivity of ethylene glycol is 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com