Liquid silicone rubber and preparation method thereof

A technology of liquid silicone rubber and base rubber, which is applied in the field of silicone rubber, can solve the problems of low transparency and use of liquid fluorosilicone rubber, and achieve good oil resistance and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

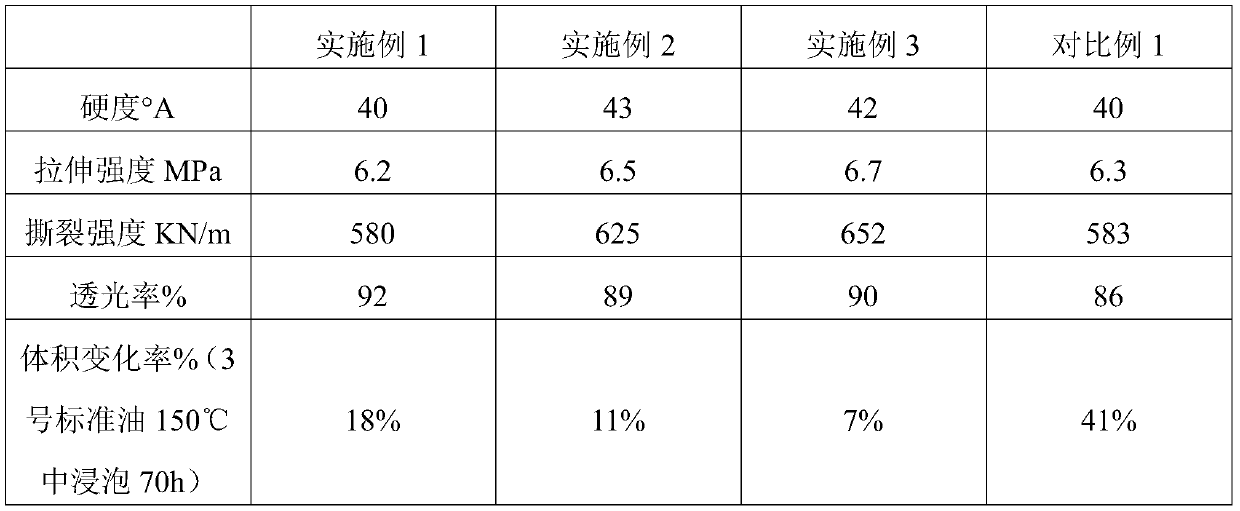

Examples

Embodiment 1

[0028] Liquid silicone rubber formula: It consists of the following raw material components in parts by weight: α, ω-divinylpolymethyltrifluoropropylsiloxane 100g, methylphenyl hydrogen silicone oil 5g, side chain vinyl copolymer Vinyl trifluoropropylsiloxane 10g, fumed silica 30g, processing aid 1g, catalyst 1g, inhibitor 0.1g.

[0029] α, ω-divinylpolymethyltrifluoropropylsiloxane has a viscosity of 4000mPa.s and a fluorine content of 30%.

[0030] The viscosity of methylphenyl hydrogen silicone oil is 150mPa.s.

[0031] The molar ratio of vinyl content to silicon-hydrogen bond content in the system is 1:1.1.

[0032] The specific surface area of fumed silica is 300m 2 / g.

[0033] Processing aid hexamethyldisilazane.

[0034] The catalyst is a chloroplatinic acid-isopropanol complex with a platinum content of 3000ppm.

[0035] The inhibitor is acetylene alcohol.

[0036] The preparation method steps are as follows:

[0037] (1) Prepare base rubber: add 100gα,ω-divi...

Embodiment 2

[0042] Liquid silicone rubber formula: It consists of the following raw material components in parts by weight: α, ω-divinylpolymethyltrifluoropropylsiloxane 100g, methylphenyl hydrogen-containing silicone oil 2g, side chain vinyl copolymer Vinyl trifluoropropylsiloxane 20g, fumed silica 40g, processing aid 2g, catalyst 0.7g, inhibitor 0.07g.

[0043] α, ω-divinylpolymethyltrifluoropropylsiloxane has a viscosity of 6000mPa.s and a fluorine content of 50%.

[0044] The viscosity of methyl phenyl hydrogen silicone oil is 100mPa.s.

[0045] The molar ratio of vinyl content to silicon-hydrogen bond content in the system is 1:1.2.

[0046] The specific surface area of fumed silica is 200m 2 / g.

[0047] Processing aid hexamethyldisilazane.

[0048] The catalyst is chloroplatinic acid-divinyltetramethyldisiloxane complex, and the platinum content is 3000ppm.

[0049] The inhibitor is acetylene alcohol.

[0050] The preparation method steps are as follows:

[0051] (1) Prepa...

Embodiment 3

[0056] Liquid silicone rubber formula: It consists of the following raw material components in parts by weight: α, ω-divinylpolymethyltrifluoropropylsiloxane 100g, methylphenyl hydrogen-containing silicone oil 1g, side chain vinyl copolymer Vinyl trifluoropropyl siloxane 5g, fumed silica 35g, processing aid 1.8g, catalyst 0.5g, inhibitor 0.05g.

[0057] α, ω-divinylpolymethyltrifluoropropylsiloxane has a viscosity of 10000mPa.s and a fluorine content of 80%.

[0058] The viscosity of methylphenyl hydrogen silicone oil is 100mPa.s.

[0059] The molar ratio of vinyl content to silicon-hydrogen bond content in the system is 1:1.3.

[0060] The specific surface area of fumed silica is 250m 2 / g.

[0061] Processing aid hexamethyldisilazane.

[0062] The catalyst is a chloroplatinic acid-divinyltetramethyldisiloxane complex with a platinum content of 4000ppm.

[0063] The inhibitor is acetylene alcohol.

[0064] The preparation method steps are as follows:

[0065] (1) Prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com