Preparation method of rare earth sulfide compound

A rare earth sulfide and rare earth compound technology, applied in chemical instruments and methods, dyeing physical treatment, inorganic pigment treatment, etc. Brightness and tinting strength, lower reaction temperature, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

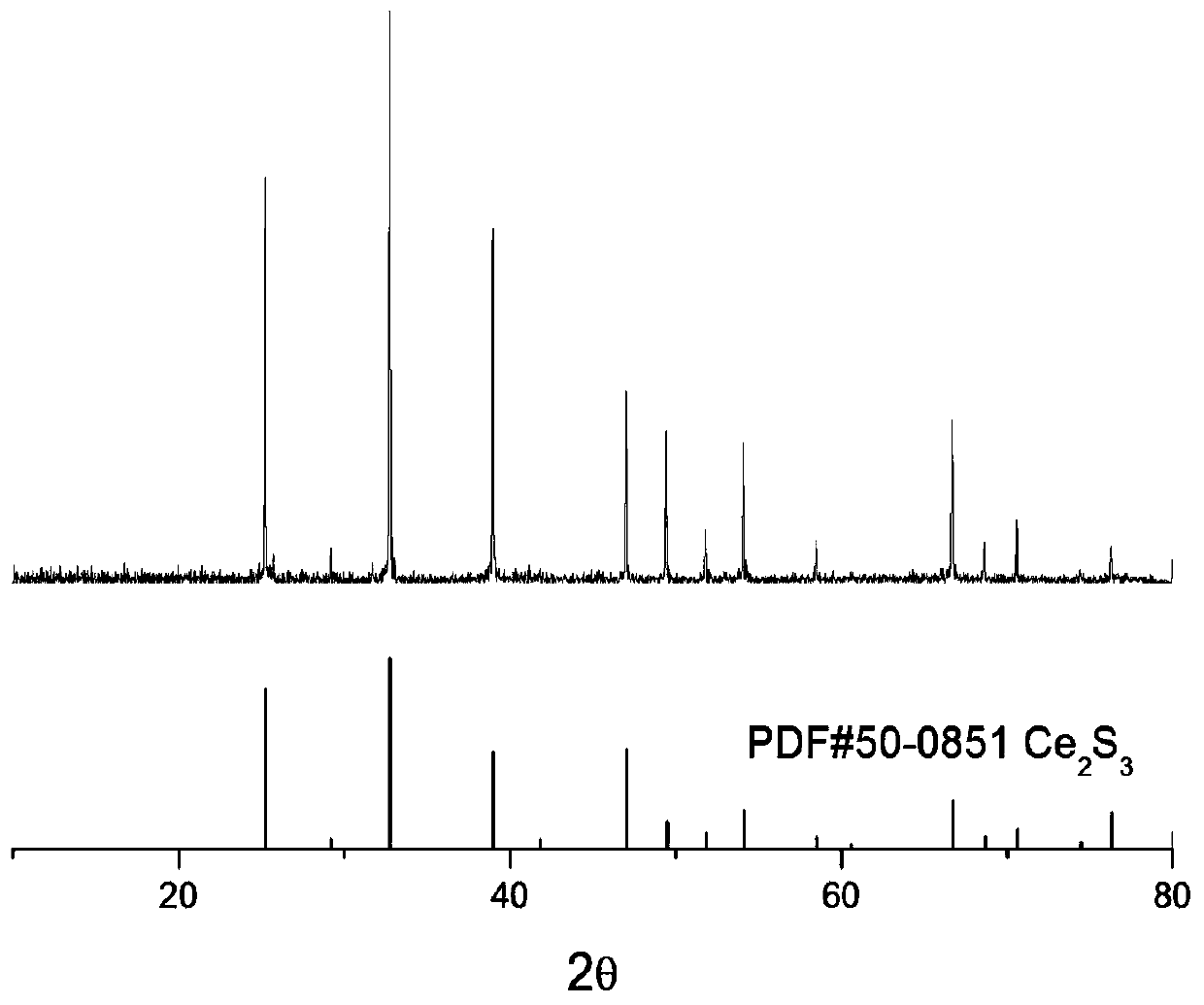

[0059] Prepare the cerium sulfide composite as follows:

[0060] (1) Dissolve 0.02mol sodium fluoride, 0.010mol sodium carbonate and 1.0g PVP in 500ml deionized water and stir for 30min to obtain solution A1.

[0061] (2) Add 0.095 mol of 1000-mesh cerium carbonate and 0.4 mol of 500-mesh sulfur to solution A1, and stir for 60 minutes to obtain suspension B1.

[0062] (3) Set the nozzle temperature of the spray drying system to 120°C, and obtain C1 after the suspension B passes through the spray drying system.

[0063] (4) Put C in the corundum crucible A, then place the crucible in the large crucible B, put 400g of activated carbon particles around the crucible A, cover it, put it in a box-type electric furnace, and pass in nitrogen to drive out the furnace cavity air, heated to 700°C, and roasted for 150 minutes to obtain the primary product of cerium oxysulfide composite;

[0064] (5) Put the obtained primary product in a beaker, add 500ml of deionized water, stir for 60 ...

Embodiment 2

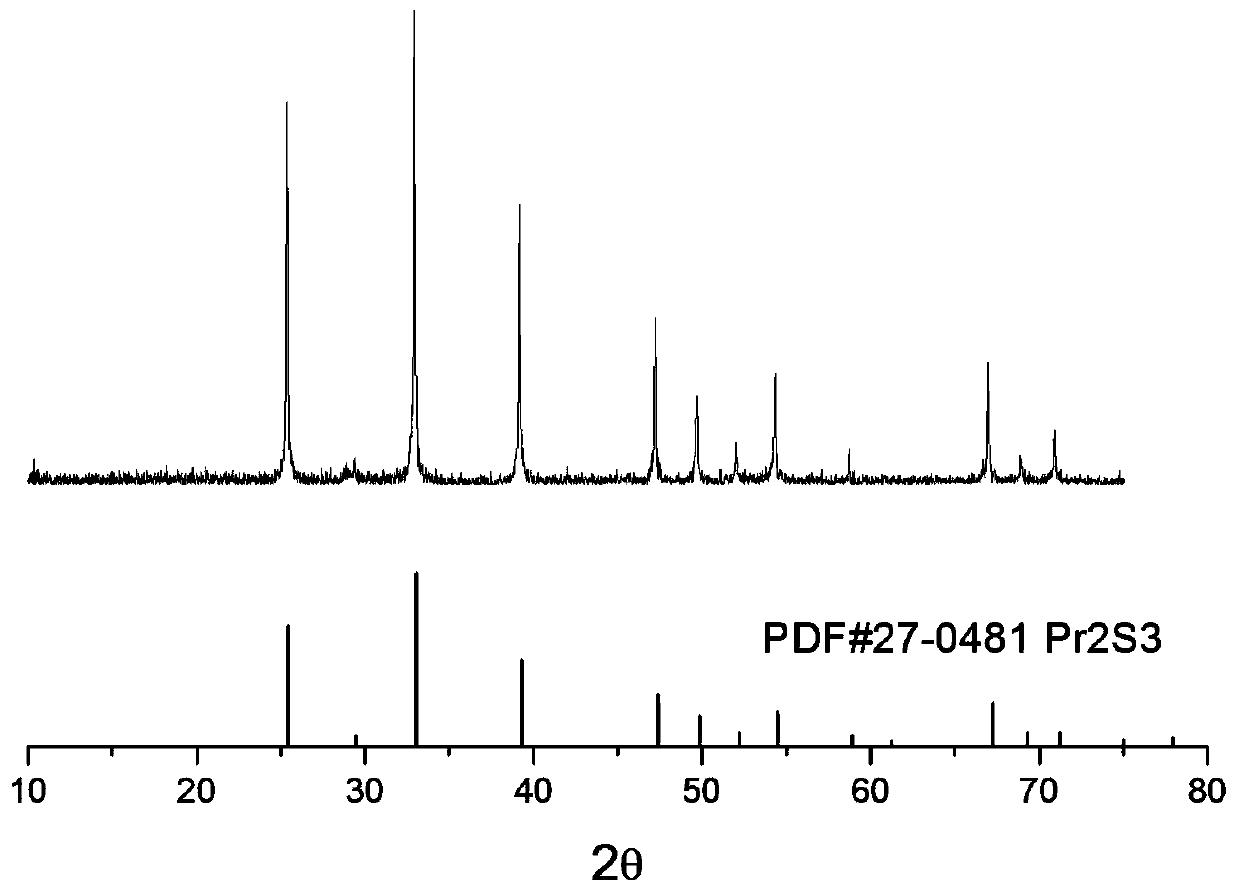

[0067] Prepare the cerium sulfide composite as follows:

[0068] (1) Dissolve 0.03mol of ammonium fluoride, 0.0015mol of sodium carbonate and 0.8g of PEG in 300ml of deionized water, and stir for 120min to obtain solution A2.

[0069] (2) Add 0.199 mol of 500-mesh cerium oxide and 0.40 mol of 1000-mesh sulfur to solution A2, and stir for 180 min to obtain suspension B2.

[0070] (3) Set the nozzle temperature of the spray drying system to 200° C., and obtain C2 after the suspension passes through the spray drying system.

[0071] (4) Put C2 in the corundum crucible A, then place the crucible in the large crucible B, put 600g of activated carbon particles around the crucible A, cover it, put it in a box-type electric furnace, and pass in argon to drive away the furnace cavity Inner air, heated up to 900°C, and roasted for 60 minutes to obtain the primary product of cerium oxysulfide composite;

[0072] (5) Put the obtained primary product in a beaker, add 300ml of deionized w...

Embodiment 3

[0075] Prepare the cerium sulfide composite as follows:

[0076] (1) Dissolve 0.01mol ammonium fluoride, 0.003mol sodium carbonate and 1.6g PVP in 400ml deionized water and stir for 90min to obtain solution A3.

[0077] (2) Add 0.099 mol of 800-mesh cerium carbonate and 1.0 mol of 800-mesh sulfur to solution A3, and stir for 90 minutes to obtain suspension B3.

[0078] (3) Set the nozzle temperature of the spray drying system to 150° C., and obtain C3 after the suspension B passes through the spray drying system.

[0079] (4) Put C3 in the corundum crucible A, then place the crucible in the large crucible B, put 500g of activated carbon powder around the crucible A, cover it, put it in the tube electric furnace, and let helium gas drive away the furnace cavity Inner air, heated up to 800°C, and roasted for 120 minutes to obtain the primary product of cerium sulfide composite;

[0080] (5) Put the obtained primary product in a beaker, add 500ml of deionized water, stir for 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com