Lactobacillus capable of producing high-yield gamma-aminobutyric acid as well as separation culture method and application of lactobacillus

An aminobutyric acid, isolation and culture technology, applied in microorganism-based methods, lactobacilli, applications, etc., can solve problems such as reducing the natural nutritional value of products, improve nutritional value and health care functions, excellent properties, and improve gastrointestinal tract. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The present embodiment provides a kind of lactobacillus high-yield gamma-aminobutyric acid, and the isolation method comprises the following steps:

[0067] (1) After diluting fermented fermented bean curd, a traditional fermented pickled product, with sterile physiological saline, spread it on bromocresol purple-MRS medium plate, and culture it at a constant temperature of 37°C for 48 hours, and screen out the bromcresol purple- Colonies that turn yellow on the MRS plate;

[0068] (2) Pick the bacterium colonies that can make the bromocresol purple-MRS flat plate turn yellow that step (1) obtains, repeat streaking culture 3 times, obtain pure species bacterium colony, carry out after Gram staining then, microscopic examination and carry out Catalase test, screen out strains with Gram staining positive and catalase test negative, and store them for later use;

[0069] (3) The strains screened in step (2) are subjected to primary screening for producing gamma-aminobutyr...

Embodiment 2

[0072] The present embodiment provides a kind of lactobacillus high-yield gamma-aminobutyric acid, and the isolation method comprises the following steps:

[0073] (1) After diluting fermented radish, a traditional fermented pickled product, with sterile physiological saline, spread it on a bromcresol purple-MRS medium plate, and culture it at a constant temperature of 37°C for 72 hours to screen out bromcresol purple-MRS Colonies that turn yellow on the plate;

[0074] (2) Pick the bacterium colonies that can make the bromocresol purple-MRS flat plate turn yellow that step (1) obtains, repeat streaking culture 3 times, obtain pure species bacterium colony, carry out after Gram staining then, microscopic examination and carry out Catalase test, screen out strains with Gram staining positive and catalase test negative, and store them for later use;

[0075] (3) The strains screened in step (2) are subjected to primary screening for producing gamma-aminobutyric acid, and the st...

Embodiment 3

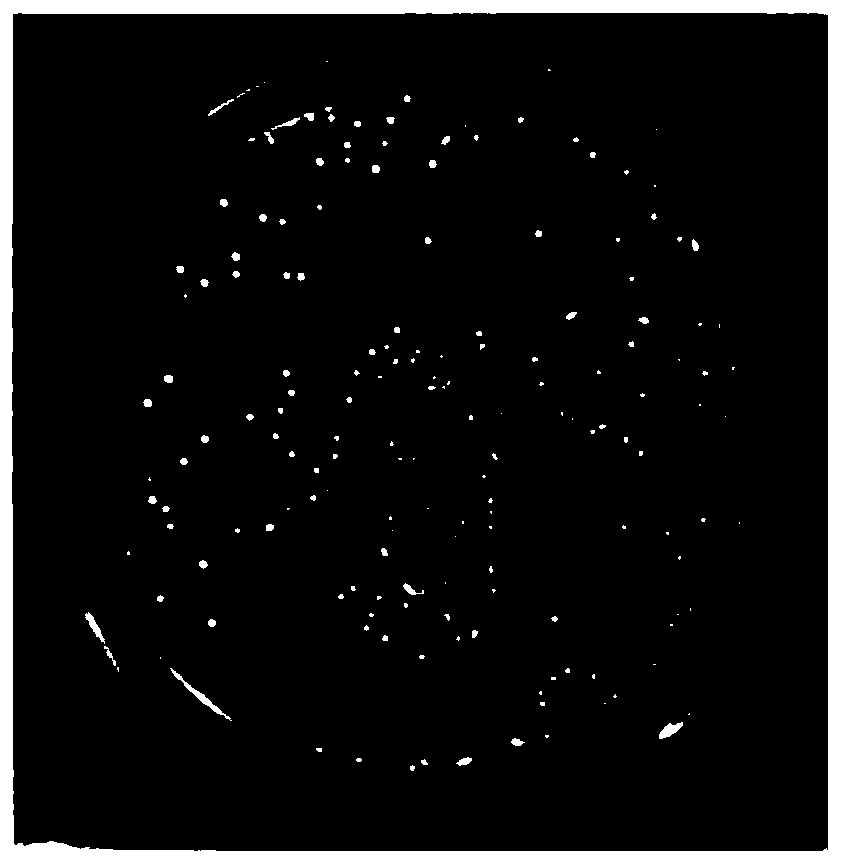

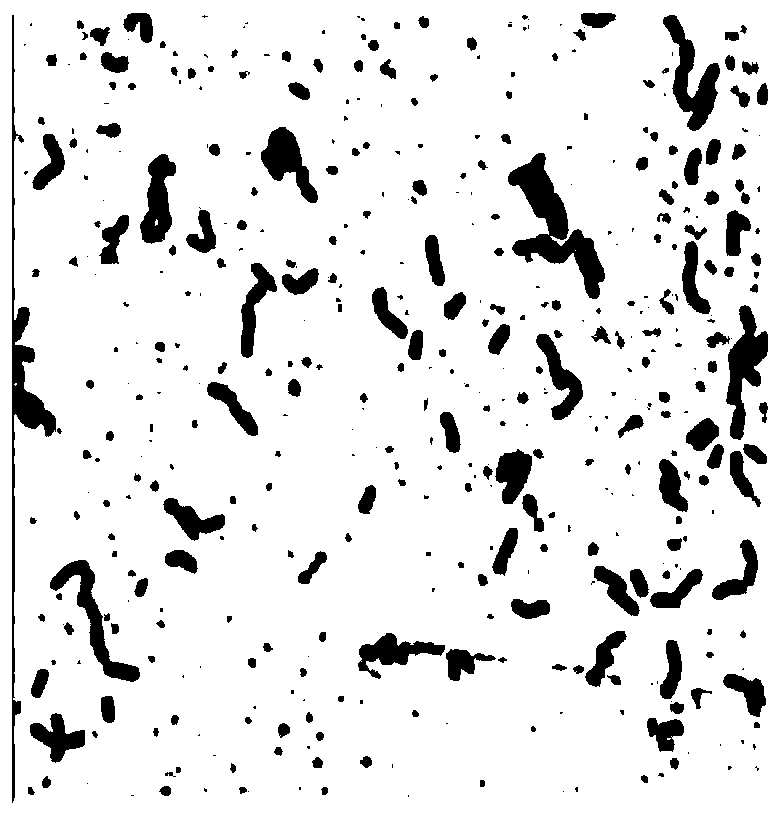

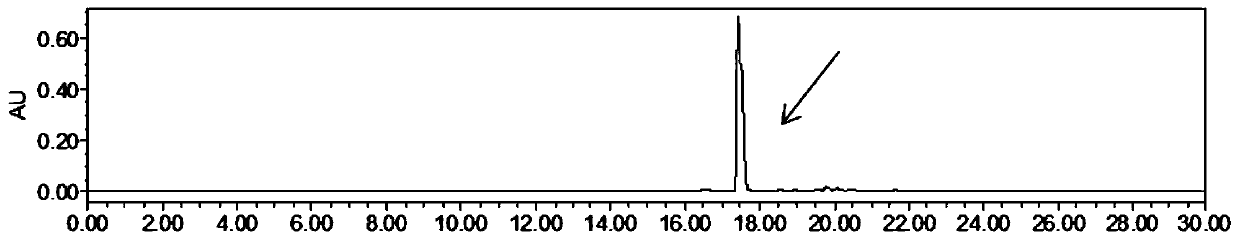

[0078] The lactobacillus screened in embodiment 1 is carried out the observation of bacterium colony form and individual form, the result is as follows figure 1 and figure 2 as shown ( figure 1 It is the colony form figure of the lactobacillus with high production of γ-aminobutyric acid of the present invention, figure 2 It is the individual morphology diagram of the lactobacillus with high γ-aminobutyric acid production in the present invention). Depend on figure 1 It can be seen that the colony of lactobacillus with high yield of gamma-aminobutyric acid of the present invention is small, the center of the colony is raised, the surface is smooth and moist, the edges are neat and complete, and acid is produced. Depend on figure 2 It can be seen that under the optical microscope, the individual shape of the lactobacillus with high yield of gamma-aminobutyric acid of the present invention is rod-shaped, and there are single, paired and chain-like existences, and these cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com