Application of modified zinc sheet

A zinc flake and modified technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of reduced cycle life and specific capacity of zinc-ion batteries, and achieve obvious performance improvement, easy operation, and good wettability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] First prepare the zinc metal disc to be modified: take a commercial pure zinc foil with a certain size and a thickness of 0.3 mm, and then use a punching machine to punch it into a disc with a diameter of 16 mm, and then punch it into a disc with a diameter of 16 mm. Use heavy objects to press the surface of the zinc metal until it is flat, and then ultrasonically clean the flattened zinc metal discs with deionized water and ethanol for 30 minutes, and then put them in an oven at 60°C to dry for use.

[0043] Secondly, the surface modification experiment was carried out: 4 pieces of zinc metal discs prepared in advance were placed in a small petri dish, and 27.2 mg of AgNO 3 Dissolve in 40ml of deionized water to obtain a 0.004M clear silver nitrate solution, and then slowly pour the solution into a small petri dish with 4 zinc metal discs, and you can immediately observe the color change on the surface of the zinc flakes. The shiny surface gradually darkens and deepens...

Embodiment 2

[0048] In order to study the optimal reaction time of the surface modification of the zinc metal negative electrode, a parallel experiment was added on the basis of Example 1. After performing the same punching and cleaning steps, 4 prepared zinc metal discs with a diameter of 16mm were soaked in 40ml0.004M AgNO 3 After reacting in the solution for about 5 minutes, take it out and let it dry in the shade to obtain the modified zinc flakes under the reaction conditions.

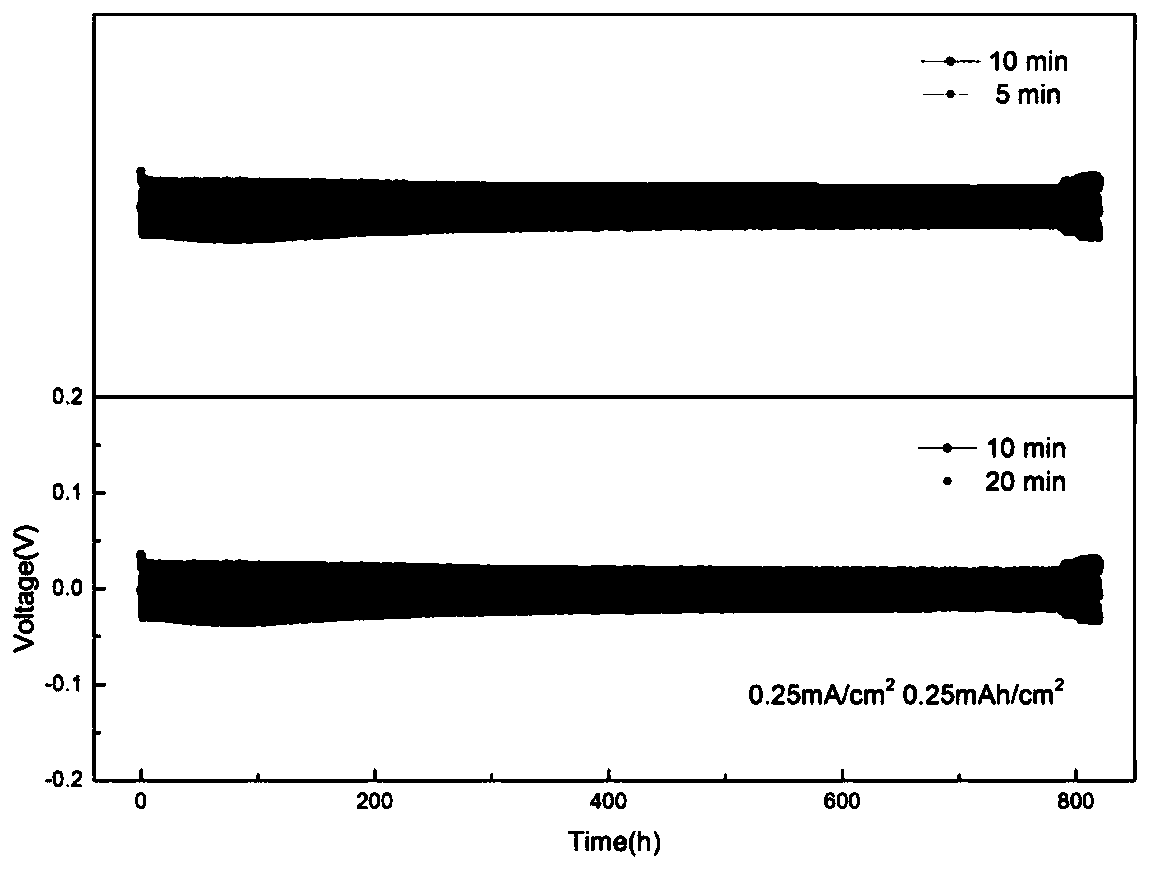

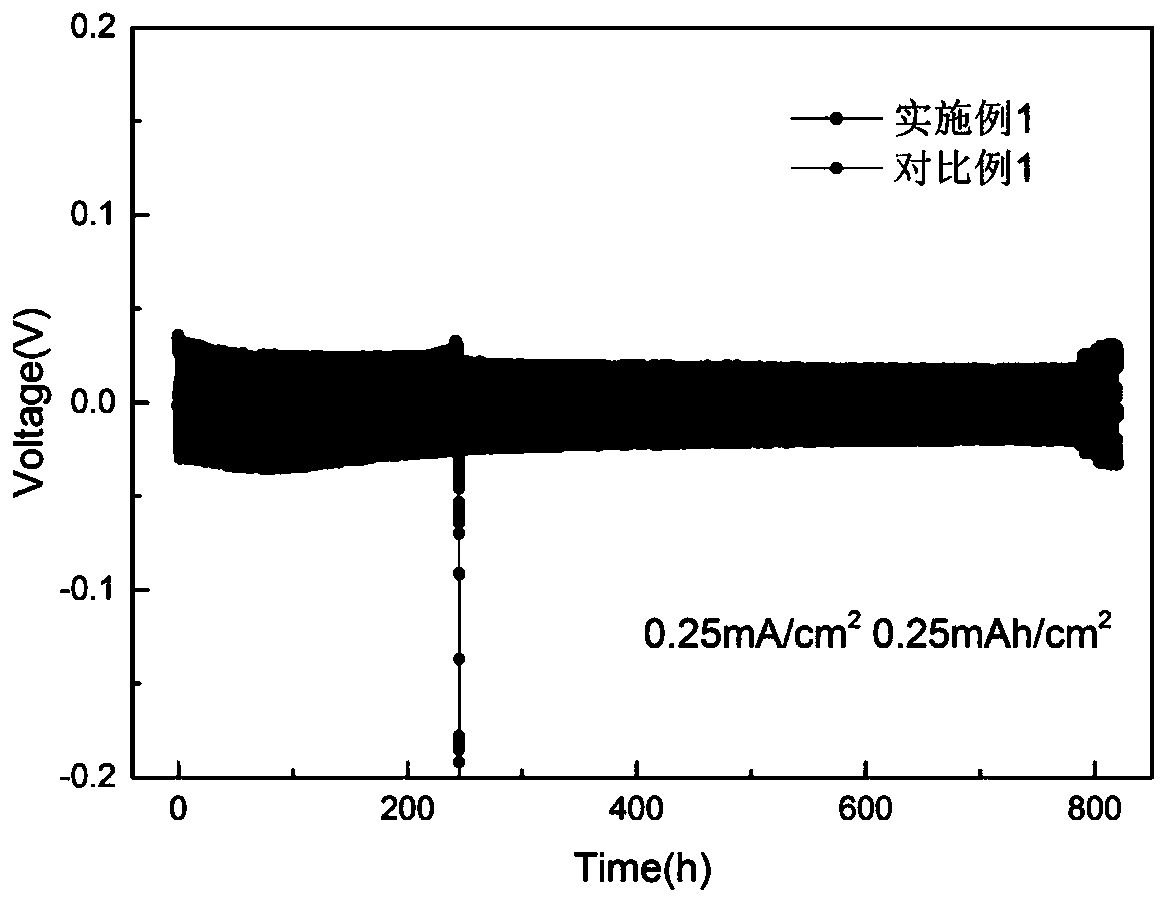

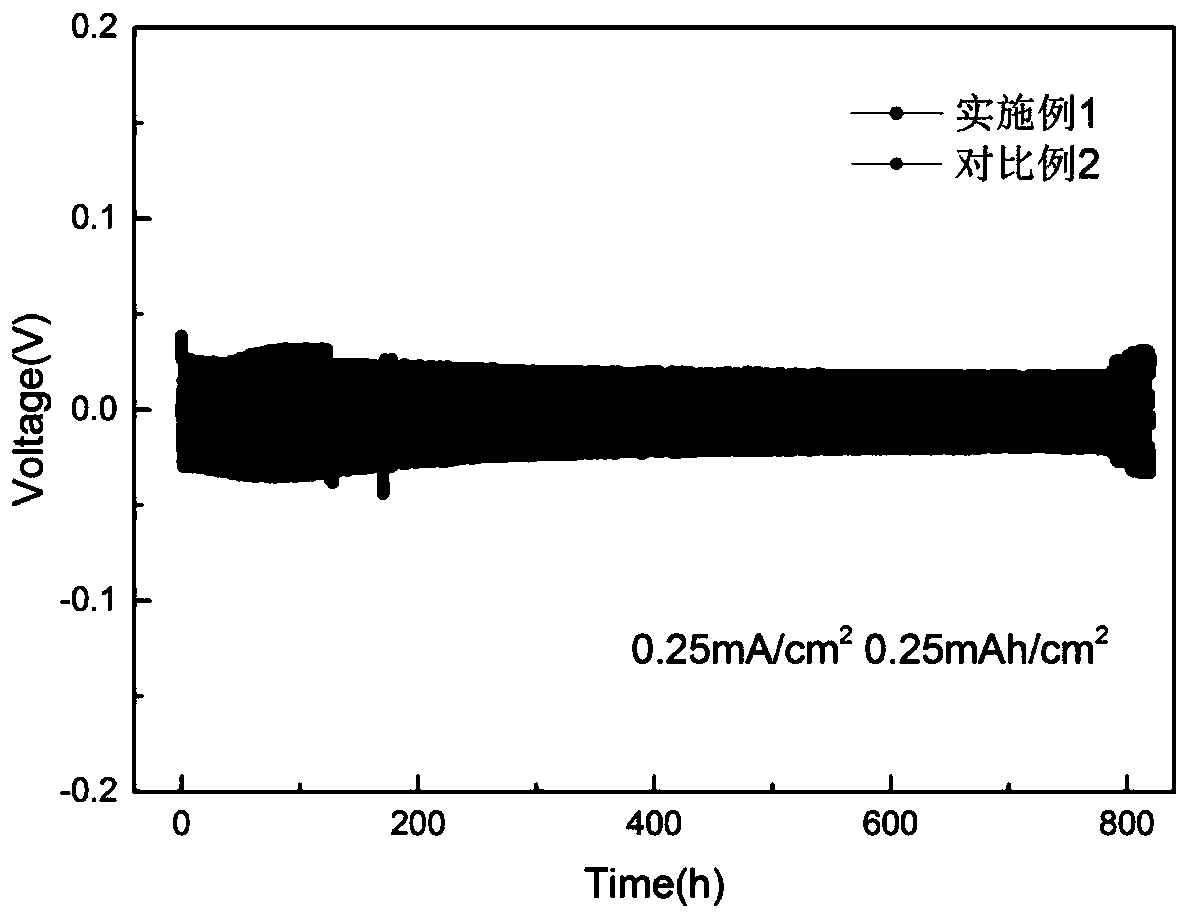

[0049] Two identical zinc sheets modified by the reaction conditions were assembled into a symmetrical battery, charged and discharged for 1 hour each at a current density of 0.25mA / cm2, as figure 1 As shown, the stable cycle can be achieved under this condition for about 600h.

Embodiment 3

[0051] Similar parallel experiment with embodiment 1, 2, the AgNO that will prepare zinc sheet soak in 40ml 0.004M 3 solution, take it out after 20 minutes and dry it under the same conditions, and finally assemble a symmetrical battery for cycle stability test, such as figure 1 As shown, the cycle time is also close to 800h under the same test conditions, which is similar to the result in Example 1.

[0052] As can be seen from the above examples, when the concentration is 0.004M, the reaction time of 10min is the best. In this reaction time, the zinc sheet reacts in the silver nitrate solution, and a large amount of silver particles are attached on its surface. It is completely covered by silver, indicating that the process of zinc deintercalation has a considerable degree of induction of uniform nucleation and deposition. As the reaction time continues to increase, since it is already a silver-coated zinc sheet, it is difficult for silver ions to regenerate. From the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap