Fuel cell bipolar plate and method

A fuel cell and bipolar plate technology, which is applied in the direction of fuel cells, fuel cell additives, electrolyte treatment of solid electrolyte batteries, etc., can solve the problem of unsatisfactory super-hydrophobic effect, achieve high-efficiency hydrophobicity, and improve performance , Enhance the effect of oxygen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] According to the preparation method of the bipolar plate of the fuel cell, the forming method of the concave-convex composite structure 3 can be stamping and forming of a finished model or laser processing and forming on the surface of the flow channel of the bipolar plate.

[0047] When the concave-convex composite structure 3 is processed on the flow channel surface of the bipolar plate by laser processing, the specific steps are: perform nanosecond laser reprocessing on the flow channel surface 2 of the bipolar plate to obtain a concave-convex composite structure on the flow channel surface 3 bipolar plates.

[0048] The parameters of the nanosecond laser are: the divergence angle is less than 1mrad, the output beam quality M 2 ≤4, the spot diameter is 40μm, the wavelength is 1064nm, the power is 30W, the single pulse energy is 1mJ, the pulse width is 1-100ns, and the repetition frequency is 1-100kHz.

[0049] When the concave-convex composite structure on the flow ...

Embodiment 1

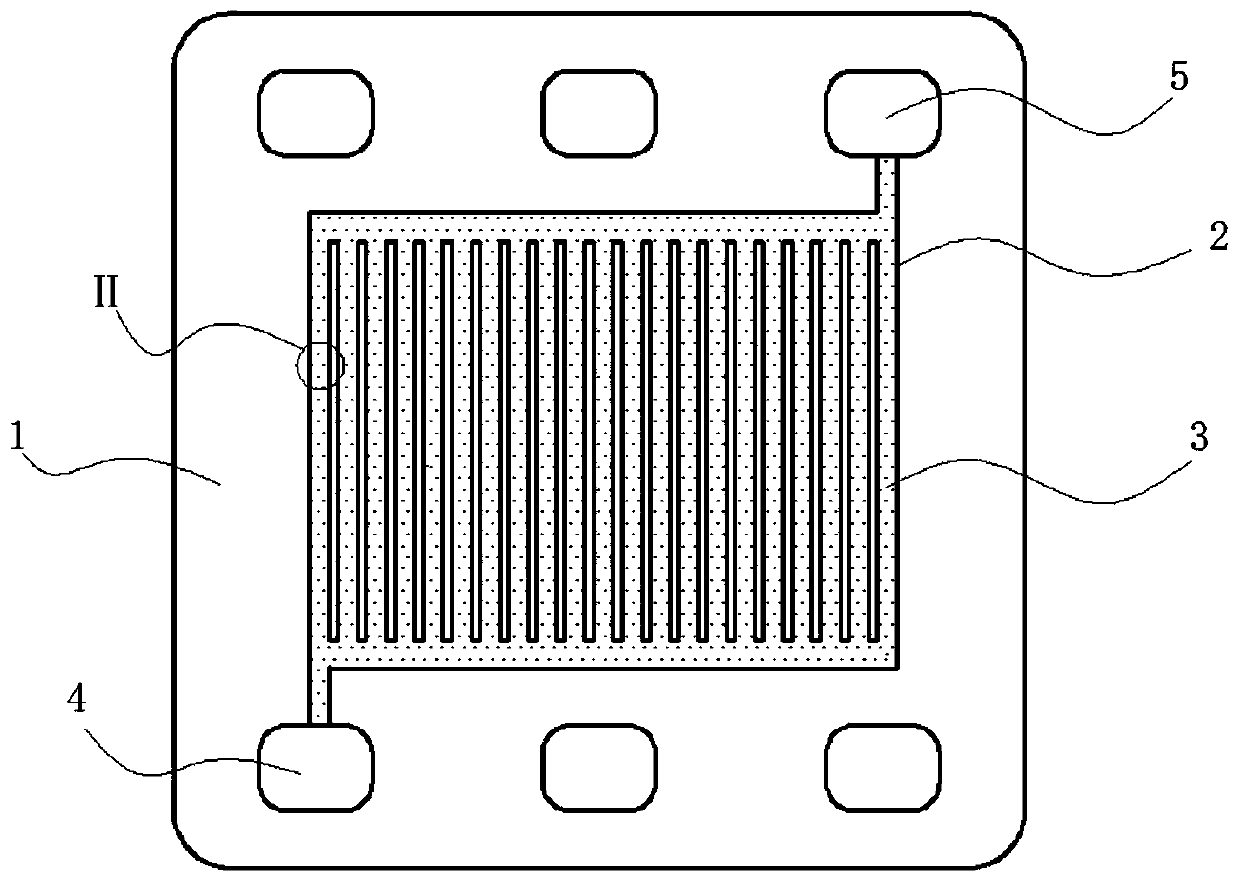

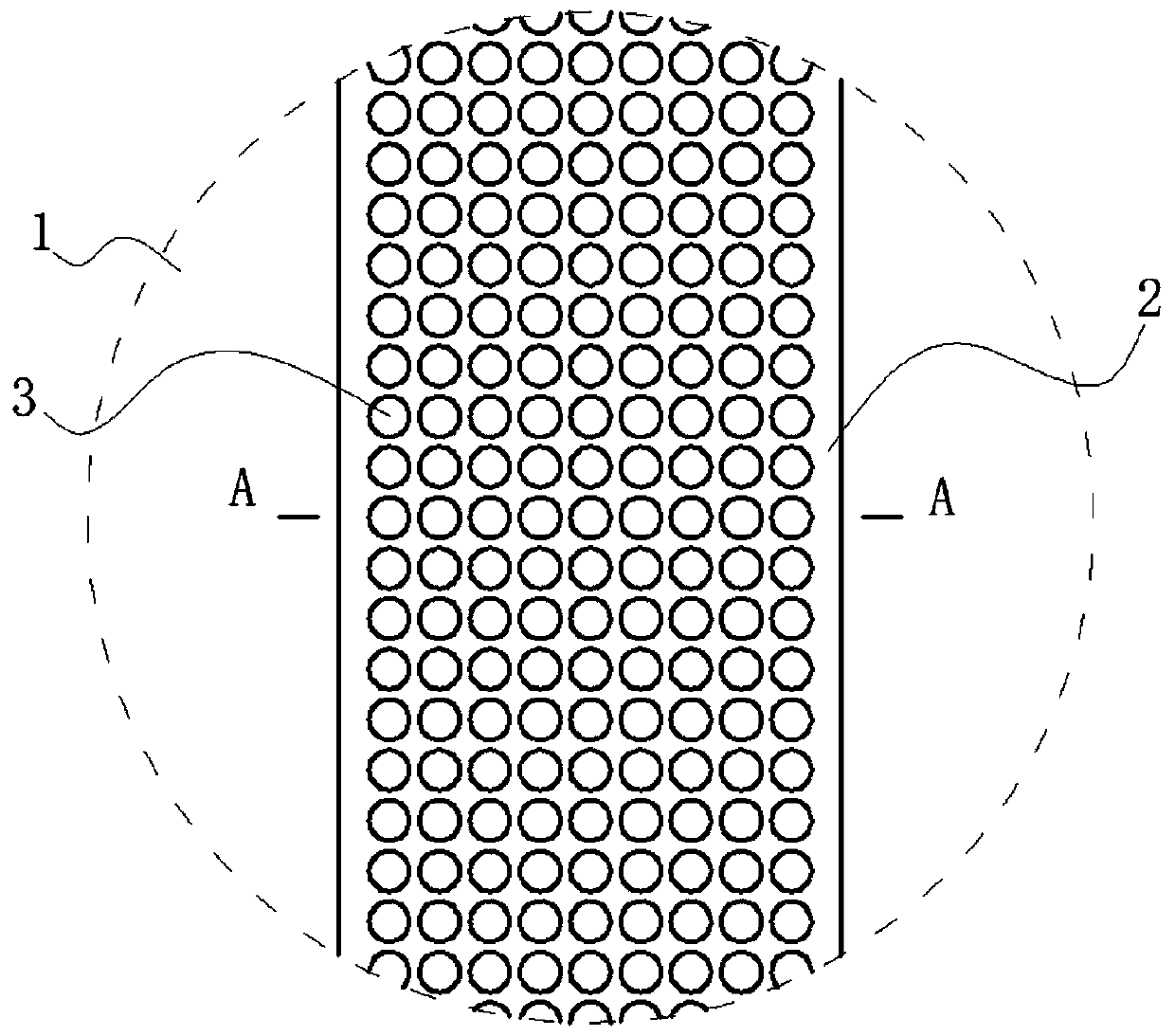

[0052] Such as figure 1 , 2 , 7, 8, a fuel cell bipolar plate, the bipolar plate material is titanium alloy, length 60mm, width 40mm, thickness 5mm. The structure of the flow channel is a parallel straight channel structure, the width of the flow channel is 1mm, and the depth of the flow channel is 1mm. The flow channel is connected to the feed port 4 and the discharge port 5 respectively, and the flow channel surface 2 of the flow channel is distributed with a plurality of concave-convex composite structures 3, and these structures are arranged in an orderly array on the entire flow field surface, so that the reacted fluid It can be discharged directly through the flow channel of the bipolar plate. The specific geometric parameters of the concave-convex composite structure 3 are: pit diameter d=23 μm, pit depth h=8 μm, protrusion height H=30 μm, convex shape top diameter D=278 μm, and the distance between the centers of two adjacent concave-convex composite structures The ...

Embodiment 2

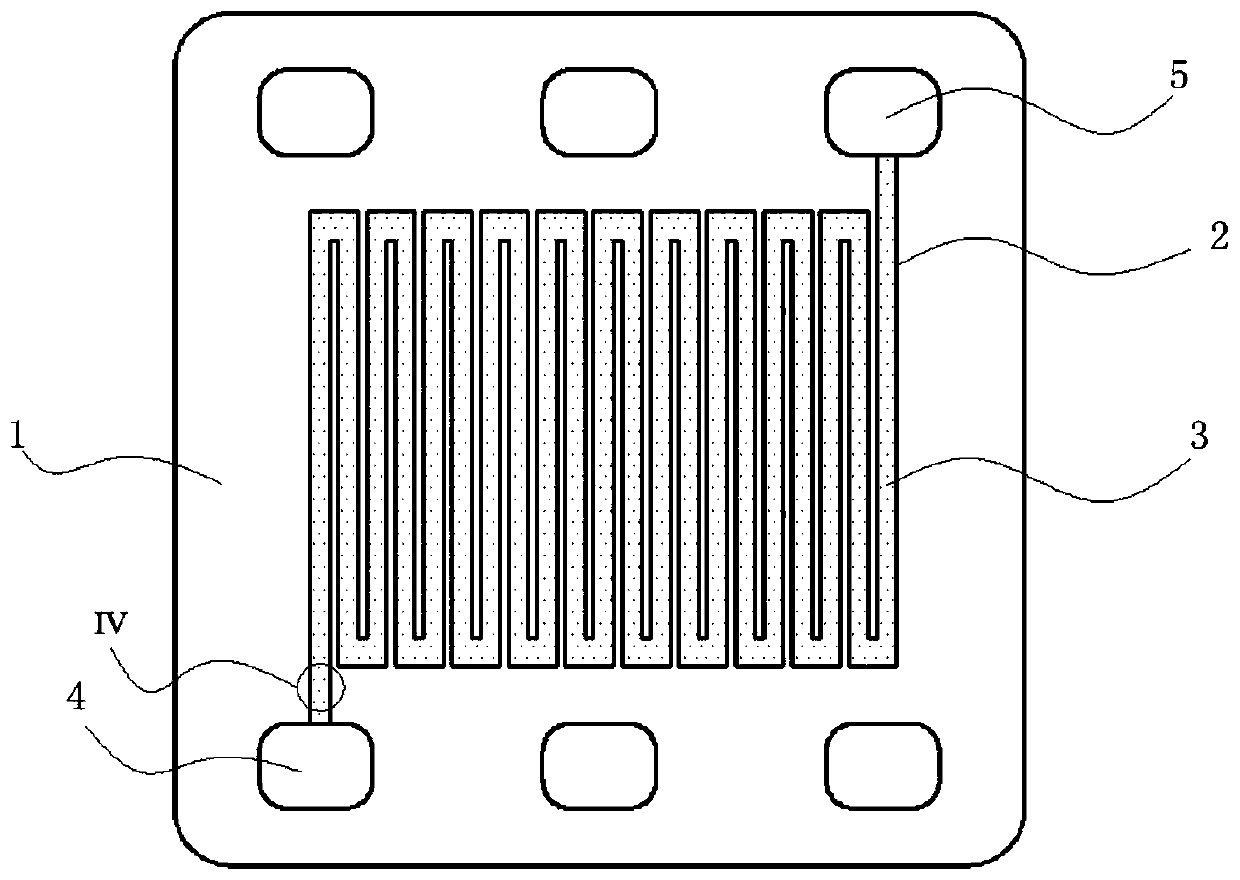

[0055] Such as image 3 , 4 , 7, 8, a fuel cell bipolar plate, the bipolar plate material is titanium alloy, length 60mm, width 40mm, thickness 5mm. The structure of the flow channel is a serpentine flow channel structure, the width of the flow channel is 1 mm, and the depth of the flow channel is 1 mm. The flow channel is connected to the feed port 4 and the discharge port 5 respectively, and the flow channel surface 2 of the flow channel is distributed with a plurality of concave-convex composite structures 3, and these structures are arranged in an orderly array on the entire flow field surface, so that the reacted fluid It can be discharged directly through the flow channel of the bipolar plate. The specific geometric parameters of the concave-convex composite structure are: pit diameter d = 200 μm, pit depth h = 60 μm, protrusion height H = 1 μm, convex topographic diameter D = 1 μm, and the distance between the centers of two adjacent concave-convex composite structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimple diameter | aaaaa | aaaaa |

| Pit depth | aaaaa | aaaaa |

| Bump height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com