Method of preparing CoPi catalyst through green recovered waste lithium cobaltate battery

A lithium cobalt oxide and catalyst technology, which is applied in the field of green recycling of waste lithium cobalt oxide batteries to prepare CoPi catalysts, can solve the problem that the value of waste lithium batteries cannot be better explored, the electrochemical energy is difficult to reach the quality of lithium cobalt oxide materials, and the global resources Shortage and other problems, to achieve the effect of increasing value, not easy to secondary pollution, simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1, see Figure 1-7 :

[0040] The invention provides a method for green recycling of waste lithium cobalt oxide batteries to prepare CoPi catalysts, comprising the following steps:

[0041] 1) Disassemble the battery, separate copper foil, aluminum foil, positive electrode material lithium cobalt oxide and negative electrode material;

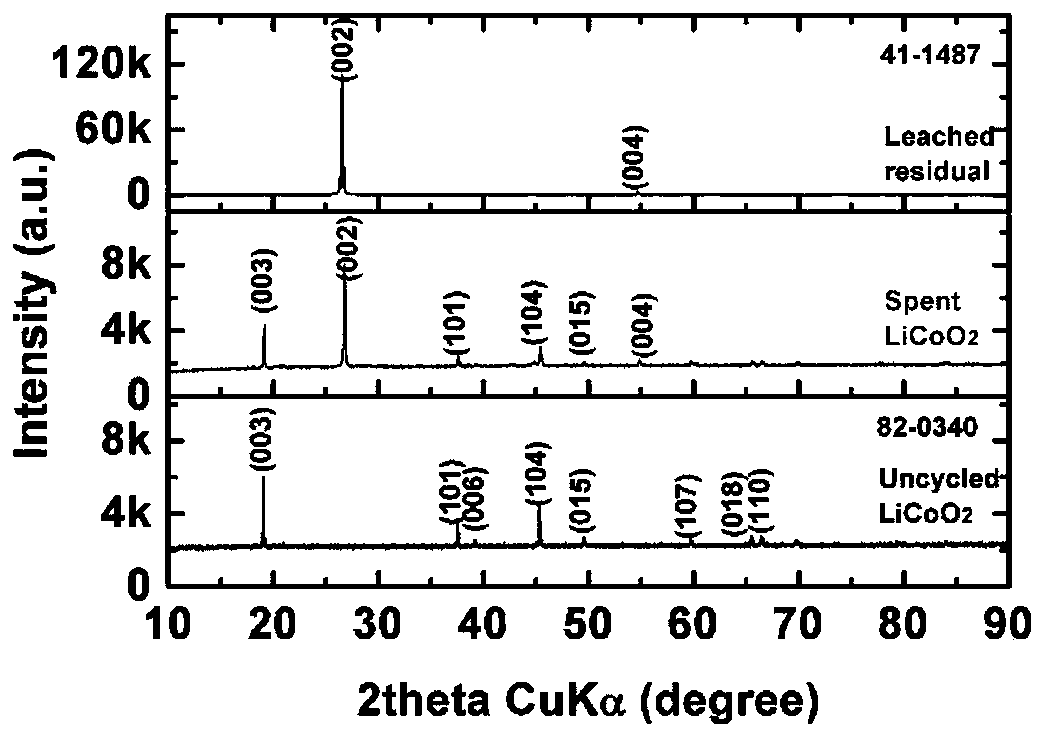

[0042] 2) First weigh 0.8406g of citric acid (4mmol), dissolve it in 16ml of deionized water, then drop 4ml of methanol into it, and finally weigh 0.098g of lithium cobaltate (see figure 2 Medium Spent LiCoO 2XRD), put it into a 25ml reaction kettle after ultrasonic dispersion for 10min, place it in a constant temperature drying oven, keep the temperature at 160°C for 10h, and dissolve it with water heat.

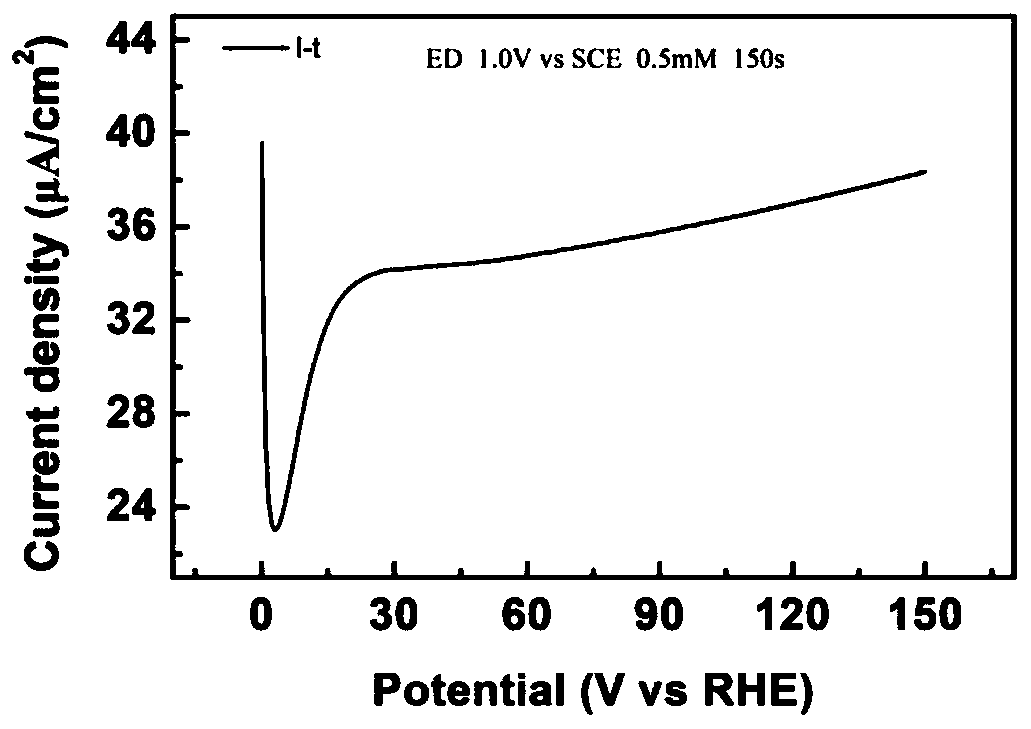

[0043] 3) Using the three-electrode deposition method, the mixture of leach solution A and phosphate buffer solution is used as the electrolyte, and the CoPi catalyst is obtained by electrodeposition on the cleaned FTO con...

Embodiment 2

[0046] Example 2, see figure 1 , 2 :

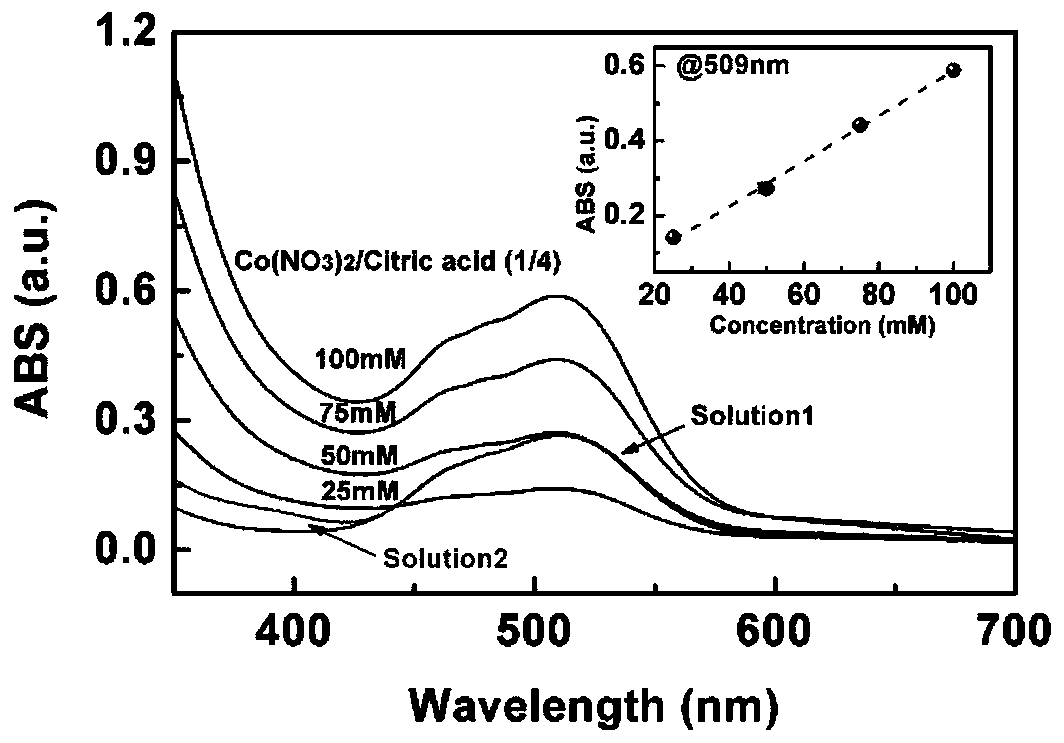

[0047] The present invention provides a kind of method that green reclaims waste lithium cobaltate battery and prepares CoPi catalyst, and wherein the specific process of dissolving is basically the same as embodiment 1, difference is: lithium cobaltate is commercial lithium cobaltate (1mmol) powder (see figure 2 Medium Uncycled LiCoO 2 XRD). The obtained leach solution A was clear and pink. as attached figure 1 As shown, the solution is basically the same as the standard solution. It shows that the method can completely dissolve the lithium cobaltate powder.

Embodiment 3

[0049] The present invention provides a method for green recycling waste lithium cobalt oxide batteries to prepare CoPi catalysts, wherein the specific process of dissolving is basically the same as that of Example 1, except that the reaction temperature is 140°C. This temperature cannot completely dissolve the substance, indicating that the dissolution temperature needs to be at least 160°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com