PPO/HIPS (polyphenyl ether/high impact polystyrene) alloy material and preparation method thereof

A technology of alloy materials and resins, which is applied in the field of PPO/HIPS alloy materials and its preparation, can solve the problems of low mechanical properties and HDT values, low thermal deformation temperature, and decreased mechanical properties of alloy materials, so as to achieve high mechanical properties and ensure mechanical Performance, Effect of High HDT Value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

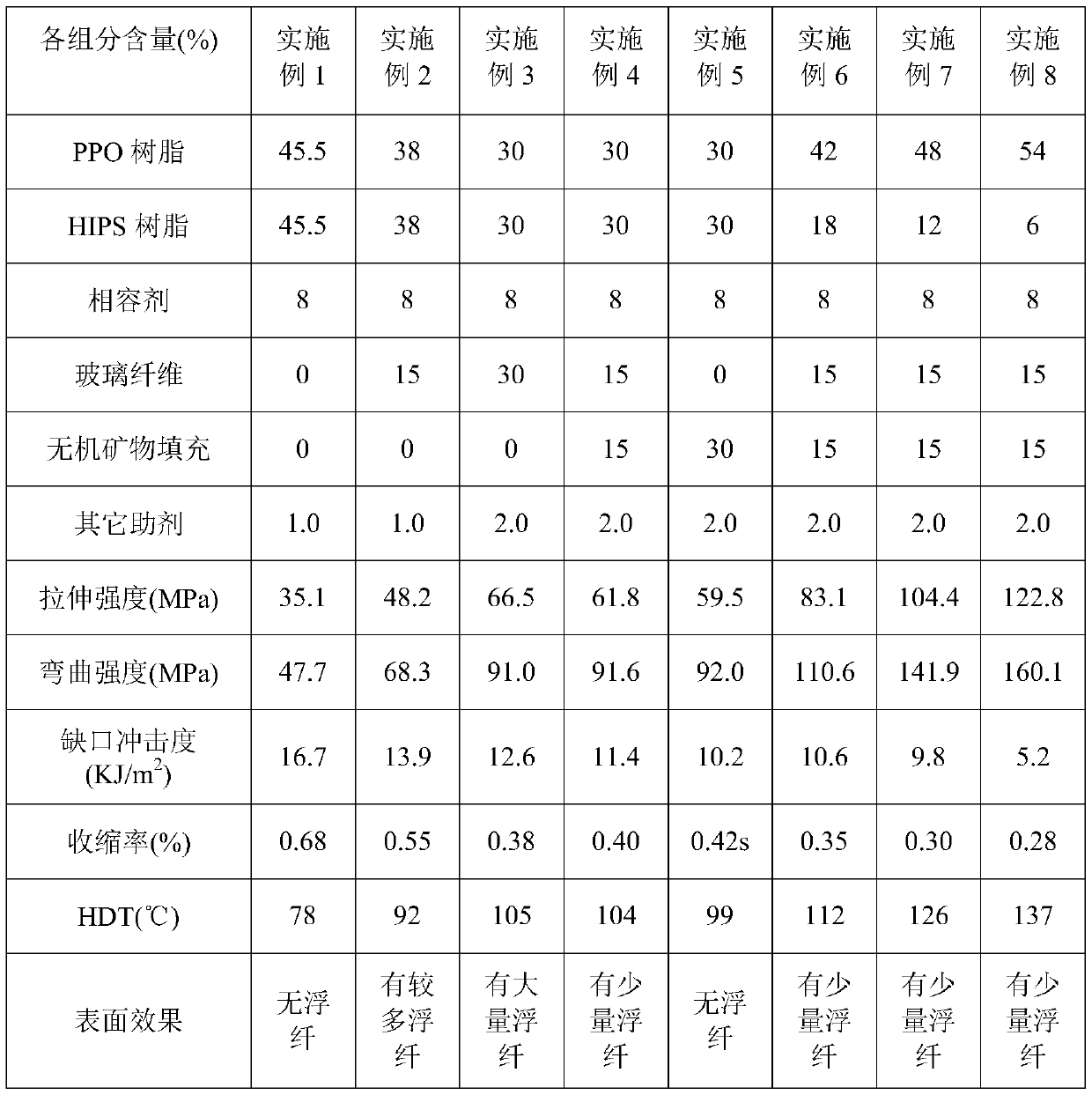

[0040] A filling reinforced modified PPO / HIPS alloy plastic, its formulation components are shown in Table 1. Wherein, used raw material is respectively:

[0041] The compatibilizer is SEBS resin.

[0042] The glass fibers are alkali-free glass fibers.

[0043] The inorganic minerals are talcum powder and / or mica.

[0044] Among the other auxiliary agents, the coupling agent is a silane coupling agent, the lubricant is a TAF lubricant, and the antioxidant is 1010 (tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propane Acid] pentaerythyl ester) and 168 (tris (2,4-di-tert-butylphenyl) phosphite) compound antioxidant.

[0045] The preparation process is as follows: adding resin and other auxiliary materials into a high-speed mixer and mixing for 2 to 5 minutes, then granulating through a twin-screw extruder, and the extrusion processing temperature is 240-270°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com