Polyaspartic acid resin luggage compartment coating and preparation method and application thereof

A technology of polyaspartic acid and luggage compartment, which is applied in the field of preparation of polyaspartic acid resin luggage compartment coatings, to achieve broad application prospects, excellent construction performance and good coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] A polyaspartic acid resin luggage compartment coating, the ratio of main raw materials: main agent: curing agent = 100 parts: 42 parts;

[0088] in:

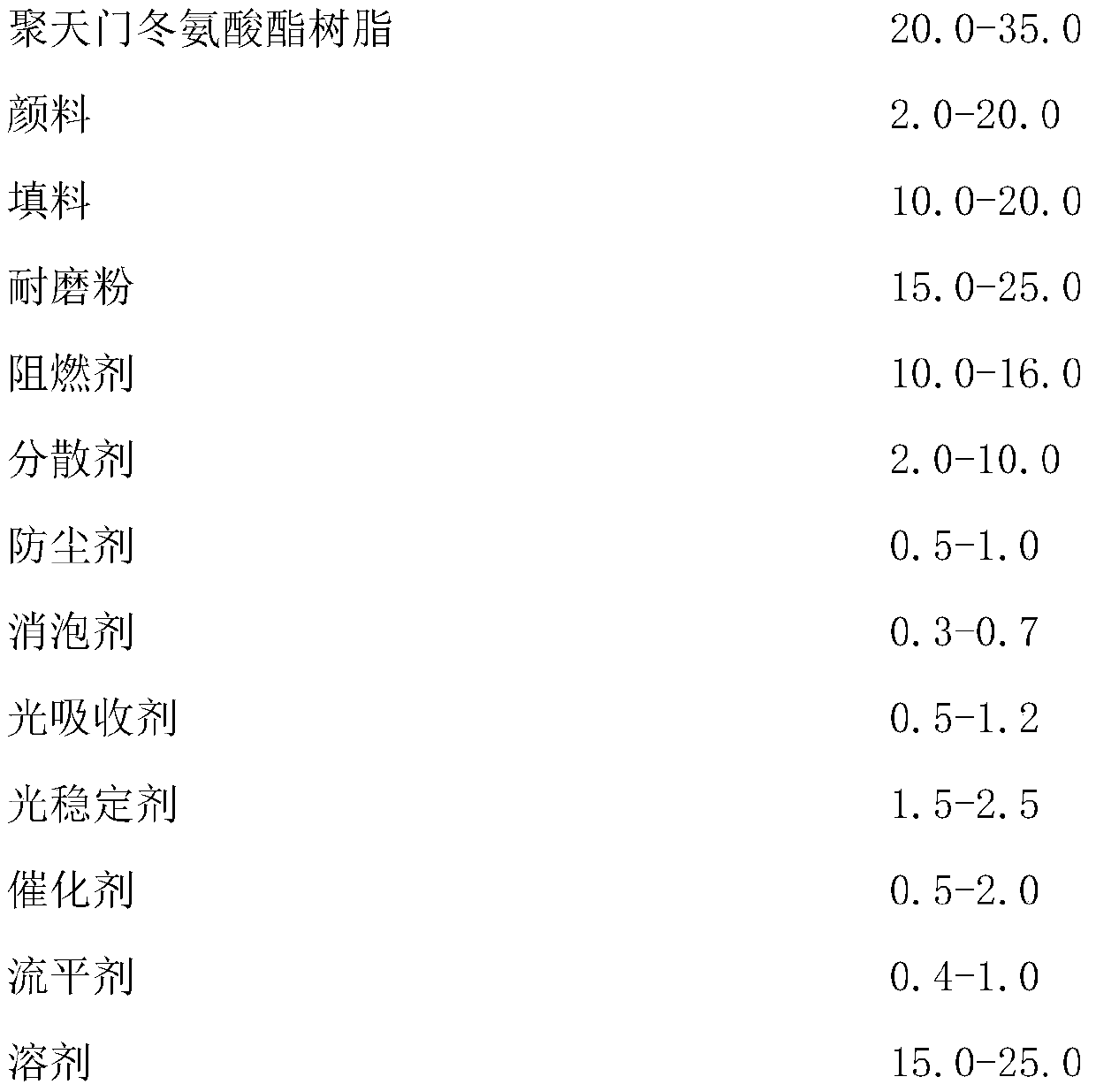

[0089] Main agent:

[0090]

[0091]

[0092] Wherein the main agent solvent ratio is:

[0093] Mixed xylene 9.0 parts

[0094] Butyl propionate 4.5 parts

[0095] Ethoxy ethyl propionate 1.5 parts

[0096] Hardener:

[0097] Polyisocyanate 72.0 parts

[0098] Water absorbent 0.2 part

[0099] Solvent 27.8 parts

[0100] Wherein the solvent proportioning in curing agent is:

[0101] Butyl propionate 25.0 parts

[0102] Ethoxy ethyl propionate 2.8 parts.

Embodiment 2

[0104] A kind of polyaspartic acid resin luggage compartment coating, main raw material ratio: main agent: curing agent=100 parts: 30 parts,

[0105] in:

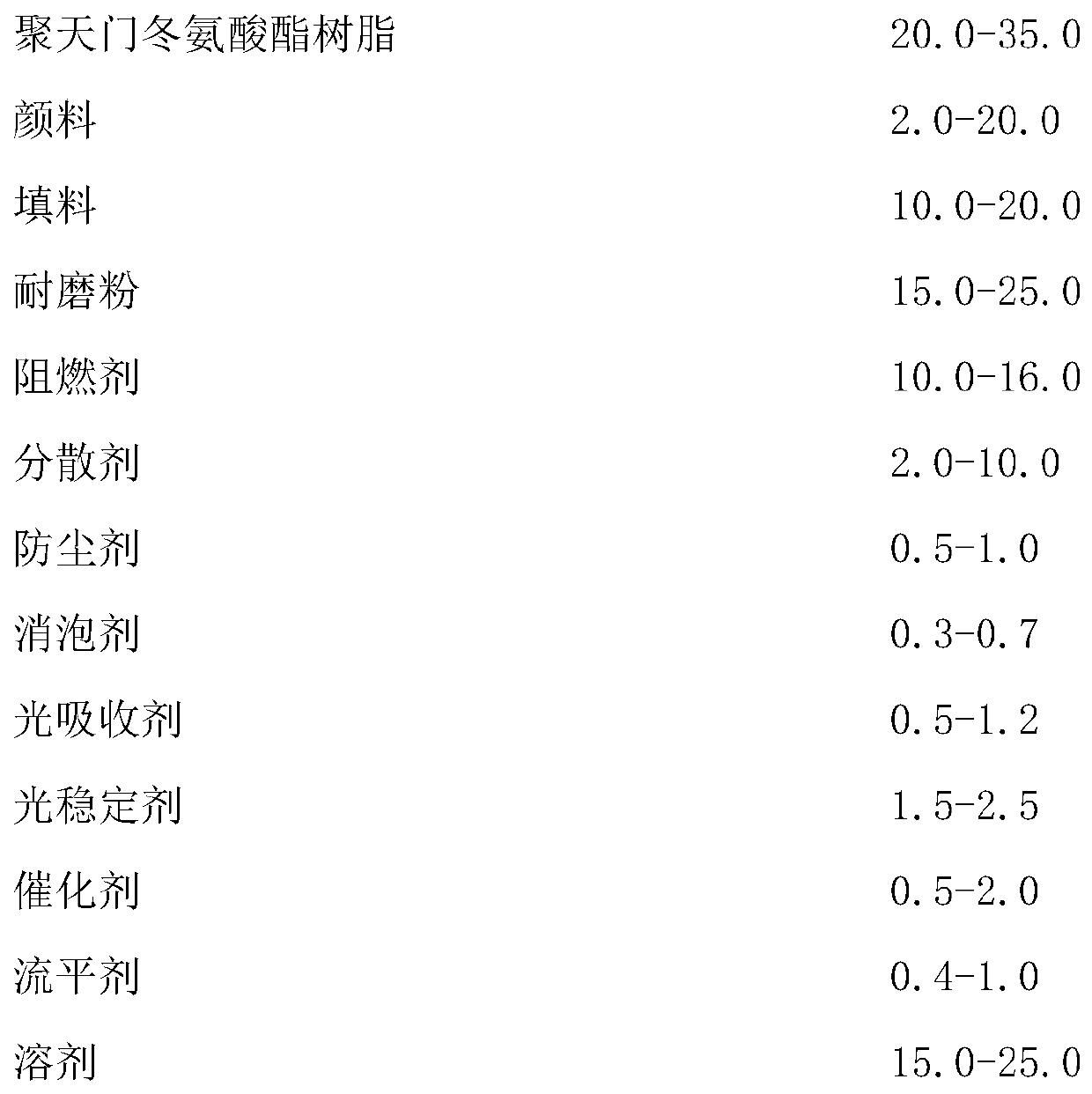

[0106] Main agent:

[0107]

[0108]

[0109] Wherein the main agent solvent ratio is:

[0110] Mixed xylene 12.0 parts

[0111] Butyl propionate 5.5 parts

[0112] Ethoxy ethyl propionate 2.5 parts

[0113] Hardener:

[0114] Polyisocyanate 75.0 parts

[0115] Water absorbent 0.3 part

[0116] Solvent 24.7 parts

[0117] Wherein the solvent proportioning in curing agent is:

[0118] Butyl propionate 24.0 parts

[0119] Ethoxy ethyl propionate 2.7 parts.

Embodiment 3

[0121] A kind of polyaspartic acid resin luggage compartment coating, main raw material ratio: main agent: curing agent=100 parts: 25 parts,

[0122] in,

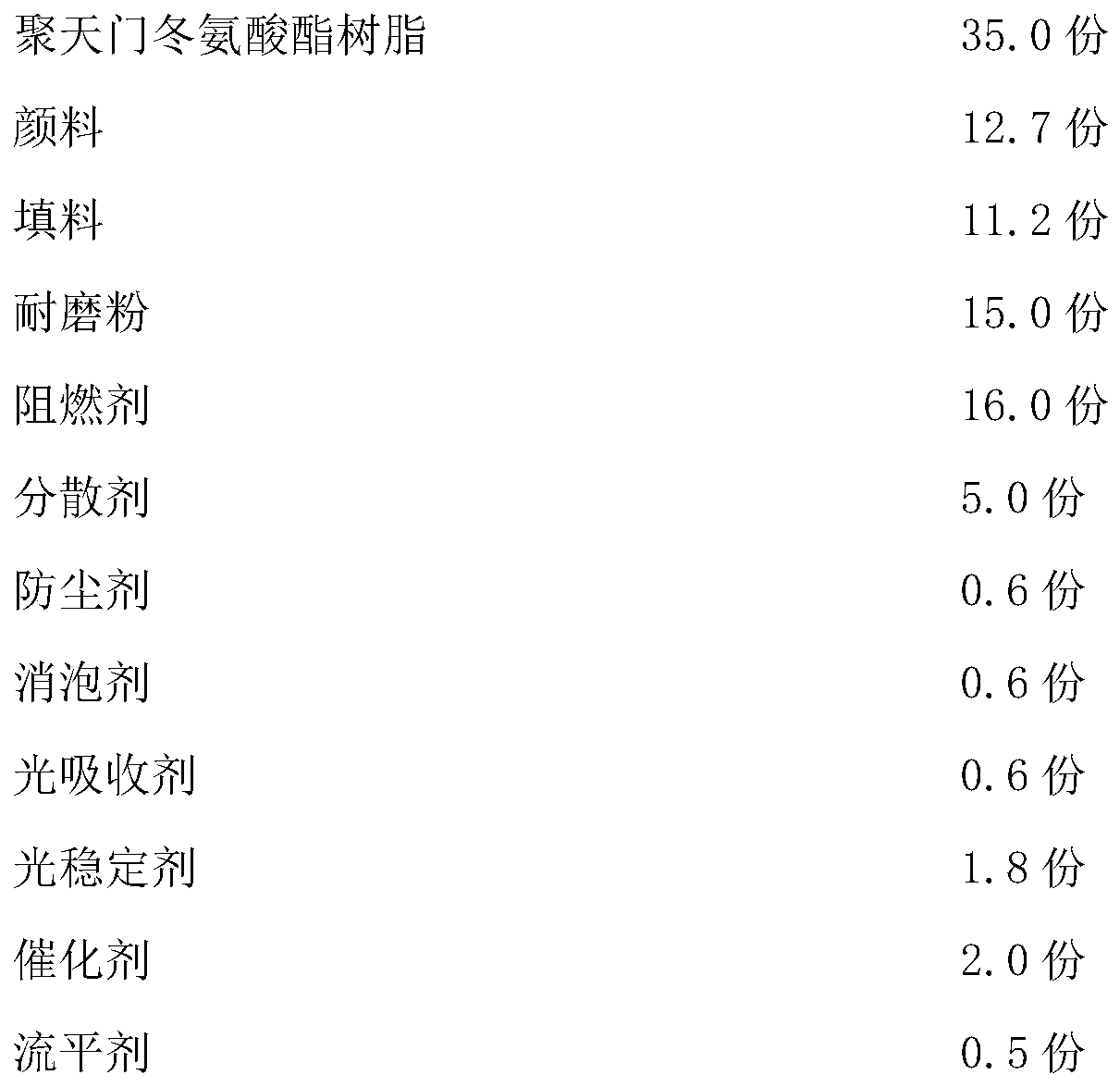

[0123] Main agent:

[0124]

[0125]

[0126] Wherein the main agent solvent ratio is:

[0127] Mixed xylene 15.0 parts

[0128] Butyl propionate 7.5 parts

[0129] Ethoxy ethyl propionate 2.5 parts

[0130] Hardener:

[0131] Polyisocyanate 80.0 parts

[0132] Water absorbent 0.5 part

[0133] 19.5 parts of solvent

[0134] Wherein the solvent proportioning in curing agent is:

[0135] Butyl propionate 17.0 parts

[0136] Ethoxy ethyl propionate 2.5 parts.

[0137] The preparation method of embodiment 1-3 coating, comprises the steps:

[0138] (1) Main ingredient preparation:

[0139]A. Ingredients: Mix the polyaspartate resin and some solvents in the above parts by weight and stir evenly, and add dispersant, flame retardant, pigment, filler, dustproof agent, defoaming agent under the stirring state of 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fire resistance | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com