Super-hydrophobic piezoresistive pressure sensor and preparation method thereof, and application of super-hydrophobic piezoresistive pressure sensor

A pressure sensor and water pressure technology, which is applied in the measurement of the property force of piezoelectric resistance materials, etc., can solve the problems of shortened service life and no waterproof function, and achieve stable electrical response signal, excellent hydrophobicity, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

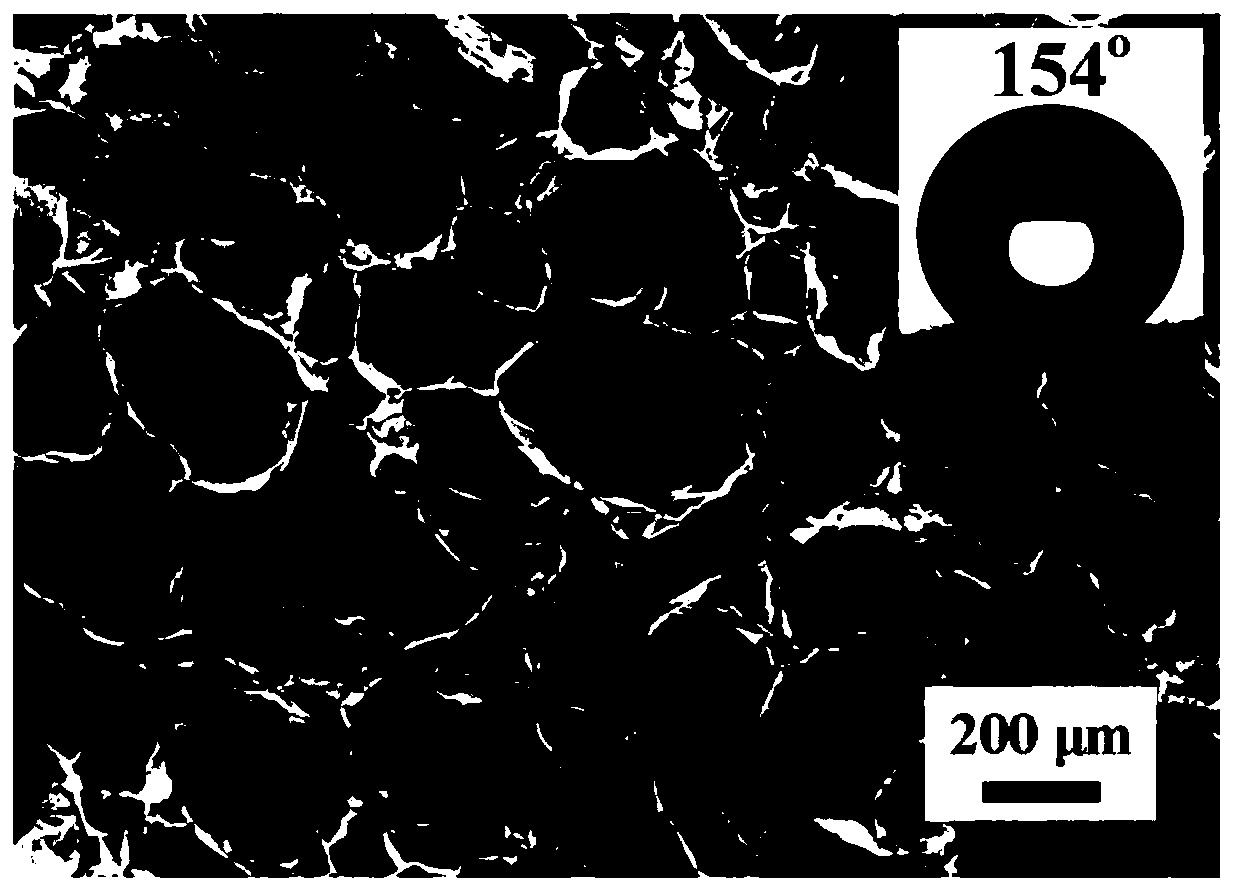

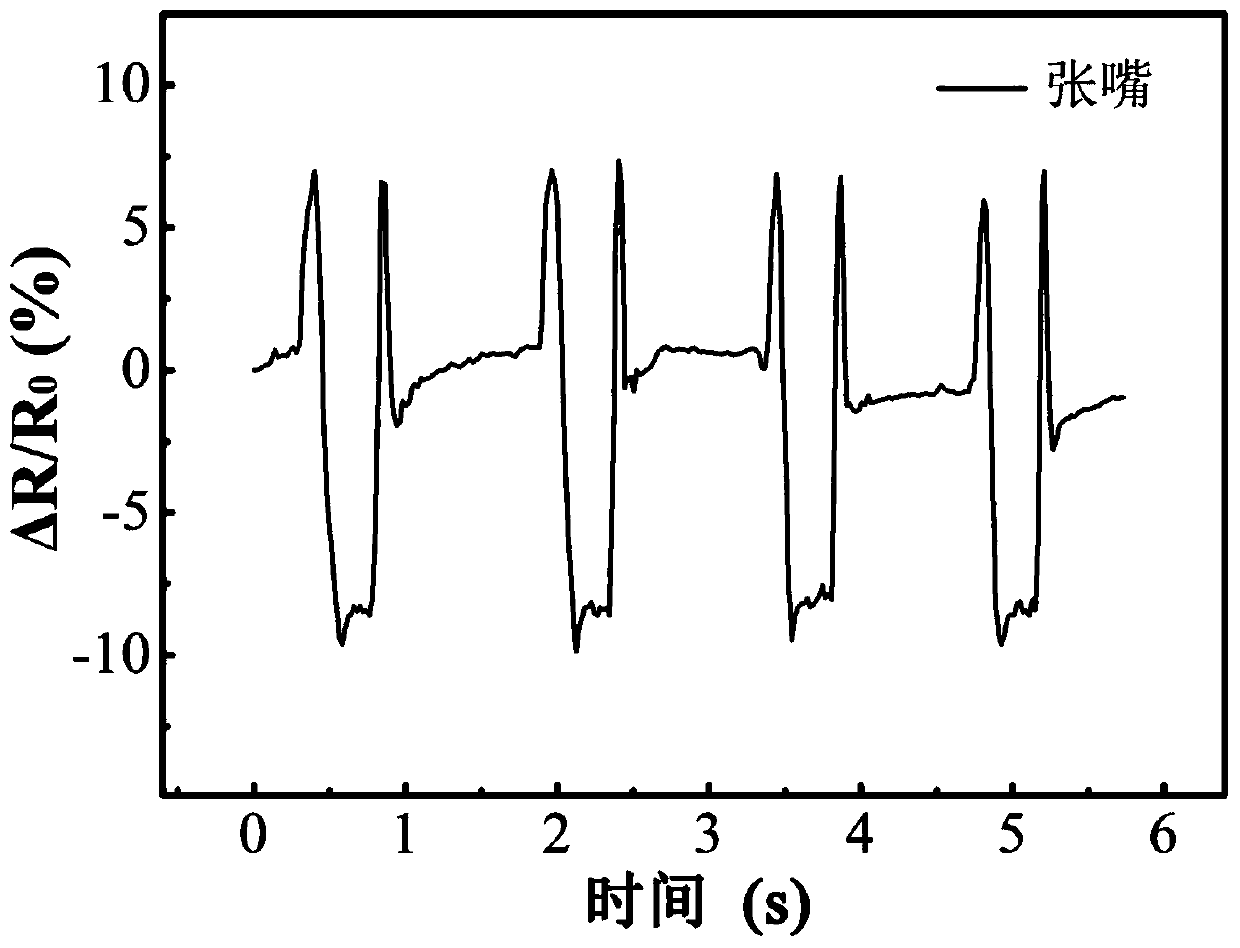

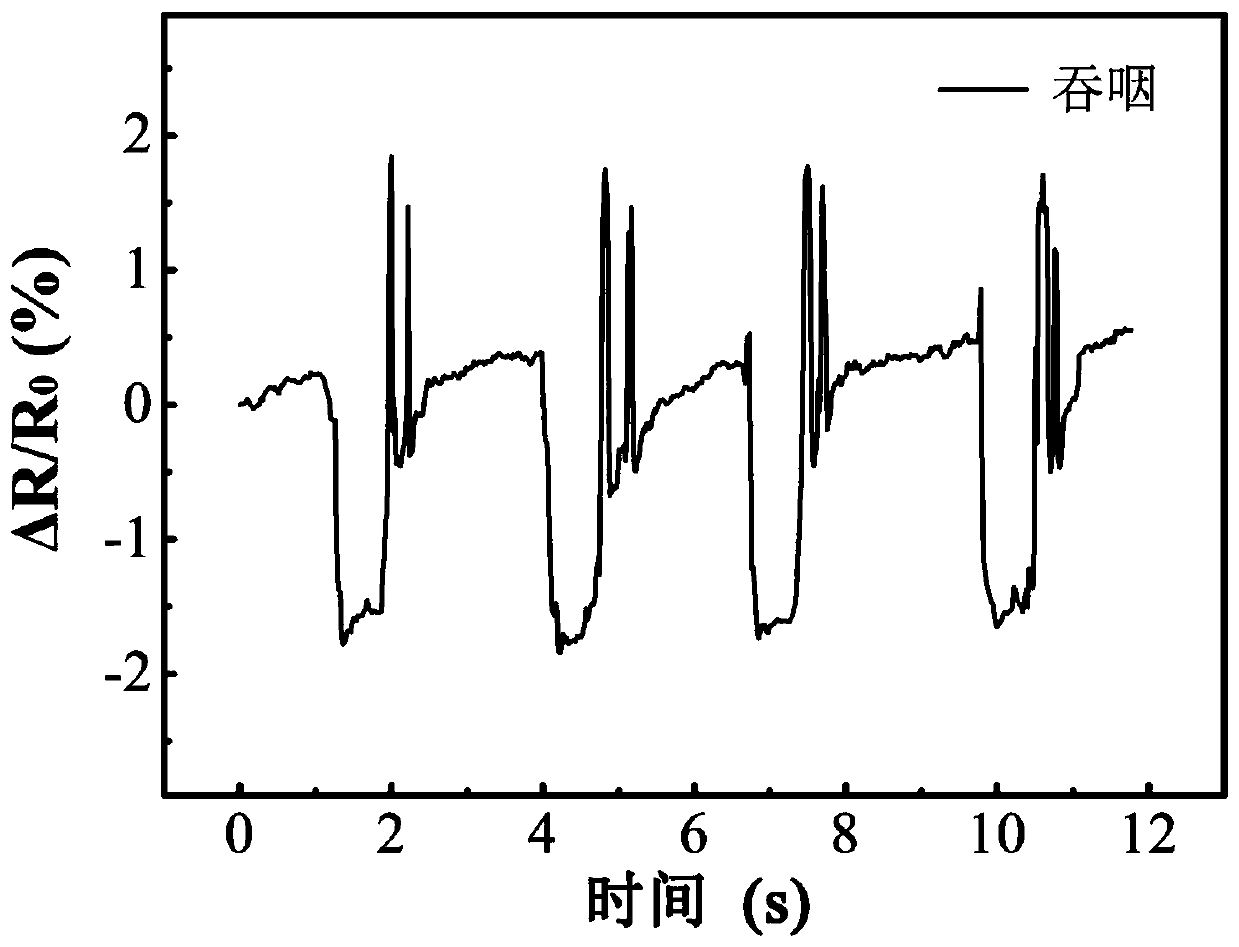

[0037] 0.25g of carboxylated carbon nanotubes were ultrasonically dispersed in 50mL of 1% acetic acid aqueous solution, and then 1g of chitosan was added under stirring. After the chitosan was completely dissolved, 0.05 g of glutaraldehyde was added dropwise, and allowed to stand at room temperature for 1 hour to cross-link to obtain a hydrogel, which was then freeze-dried for 48 hours to obtain an airgel. The airgel was immersed in 2mg / mL graphene oxide (prepared according to the modified Hummers method, Zhang L, Li HQ, Lai XJ, et al. Thiolated graphene-basedsuperhydrophobic sponges for oil-water separation. Chemical Engineering Journal, 2017, 316, 736– 743) solution (water and N,N-dimethylformamide as solvent, volume ratio 1:3) for 5 min. After taking it out, immerse it in 20mg / mL ascorbic acid solution, and reduce it at 70°C for 2h. Finally, soak it in the ethanol solution of 1wt% perfluorooctyl triethoxysilane for 12 hours, take it out and rinse it with absolute ethanol, ...

Embodiment 2

[0045] 0.33 g of carboxylated carbon nanotubes were ultrasonically dispersed in 50 mL of 1% acetic acid aqueous solution, and then 1 g of chitosan was added under stirring. After the chitosan was completely dissolved, 0.05 g of glutaraldehyde was added dropwise, left to stand at room temperature for 0.5 h to cross-link to obtain a hydrogel, and then freeze-dried for 24 h to obtain an airgel. The airgel was immersed in a 2 mg / mL graphene oxide solution (water and N,N-dimethylformamide as solvent, volume ratio 1:3) for 5 min. After taking it out, immerse it in 20mg / mL ascorbic acid solution, and reduce it at 70°C for 2h. Finally, soak it in the ethanol solution of 1wt% perfluorooctyl triethoxysilane for 18 hours, take it out and rinse it with absolute ethanol, dry it at 60°C for 12 hours, and stick electrodes on both ends to obtain superhydrophobic pressure. Resistive pressure sensor. Specifically, copper sheets are pasted on the upper and lower surfaces of the airgel with con...

Embodiment 3

[0049] 0.43g of carboxylated carbon nanotubes were ultrasonically dispersed in 50mL of 1% acetic acid aqueous solution, and then 1g of chitosan was added under stirring. After the chitosan was completely dissolved, 0.75 g of glutaraldehyde was added dropwise, left to stand at room temperature for 2 hours to cross-link to obtain a hydrogel, and then freeze-dried for 36 hours to obtain an airgel. The airgel was immersed in 2 mg / mL graphene oxide solution (water and N,N-dimethylformamide as solvent, volume ratio 2:3) for 5 min. After taking it out, immerse it in 20mg / mL ascorbic acid solution, and reduce it at 70°C for 2h. Finally, soak it in the ethanol solution of 1wt% perfluorooctyl triethoxysilane for 24 hours, take it out and rinse it with absolute ethanol, dry it at 60°C for 12 hours, and stick electrodes on both ends to obtain superhydrophobic pressure. Resistive pressure sensor. Specifically, copper sheets are pasted on the upper and lower surfaces of the airgel with co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com