A method for denitrification of waste incineration flue gas by using ammonia in landfill leachate

A technology for landfill leachate and waste incineration, which is applied in the field of denitrification of waste incineration flue gas, can solve problems such as high ammonia nitrogen, and achieve the effects of high denitration efficiency, cost saving, and reduction of inorganic matter content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

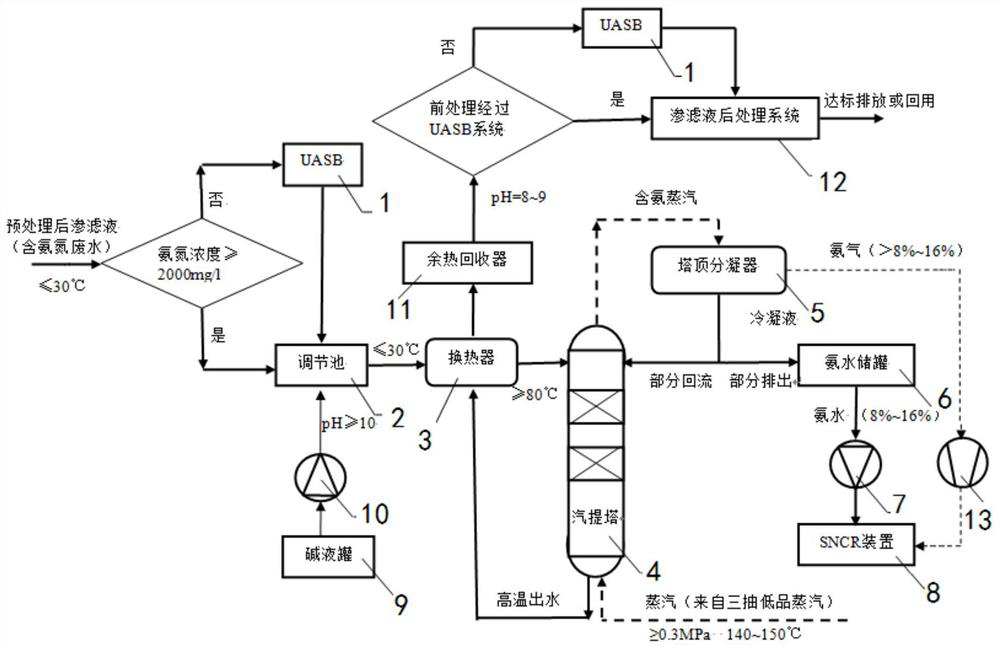

[0033] Embodiment 1: as figure 1 As shown, taking a large-scale waste incinerator with a processing capacity of 500t / d as an example, under rated operating conditions, the flue gas flow at the outlet of the waste heat boiler is about (80000-100000) Nm 3 / h, the temperature is about 190-240°C, and the concentration of nitrogen oxides in the flue gas pollutants is about 300-400mg / Nm 3 (NO accounted for 92.5%, NO 2 Accounting for 7.5%), the calculated denitrification rate of 60% required 16% concentration of ammonia water is about 126kg / h, and for domestic waste with a processing capacity of 500t, the designed landfill leachate volume is generally 250t / d, and the ammonia nitrogen content is about 2000mg / L, the ammonia content is about 20.6kg / h through the stripper, and (the ammonia collection rate is 99%) is prepared into about 128kg / h of 16% concentration of ammonia. Therefore, for landfill leachate with a production volume of 250t / d and an ammonia nitrogen content of about 2...

Embodiment 2

[0044] Embodiment 2: as figure 1 As shown, taking a large-scale waste incinerator with a processing capacity of 500t / d as an example, under rated operating conditions, the flue gas flow at the outlet of the waste heat boiler is about (80000-100000) Nm 3 / h, the temperature is about 190-240°C, and the concentration of nitrogen oxides in the flue gas pollutants is about 300-400mg / Nm 3 (NO accounted for 92.5%, NO 2 Accounting for 7.5%), according to theoretical calculation, the denitrification rate of 60% requires about 126kg / h of 16% concentration of ammonia water, and for domestic waste with a processing capacity of 500t, the designed landfill leachate volume is generally 250t / d, and the ammonia nitrogen content is about 1000mg / L, the ammonia content collected by the stripper is about 10.3kg / h, and the ammonia water with a concentration of 16% is about 64.4kg / h, which cannot meet the amount of ammonia water used for flue gas denitrification. Therefore, for landfill leachate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com