A kind of landfill leachate treatment method

A landfill leachate and treatment method technology, which is applied in the field of landfill leachate treatment, can solve problems such as C/N ratio imbalance, phosphorus element deficiency, and impact on biological treatment effects, and achieve high economic benefits and reduce organic matter content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

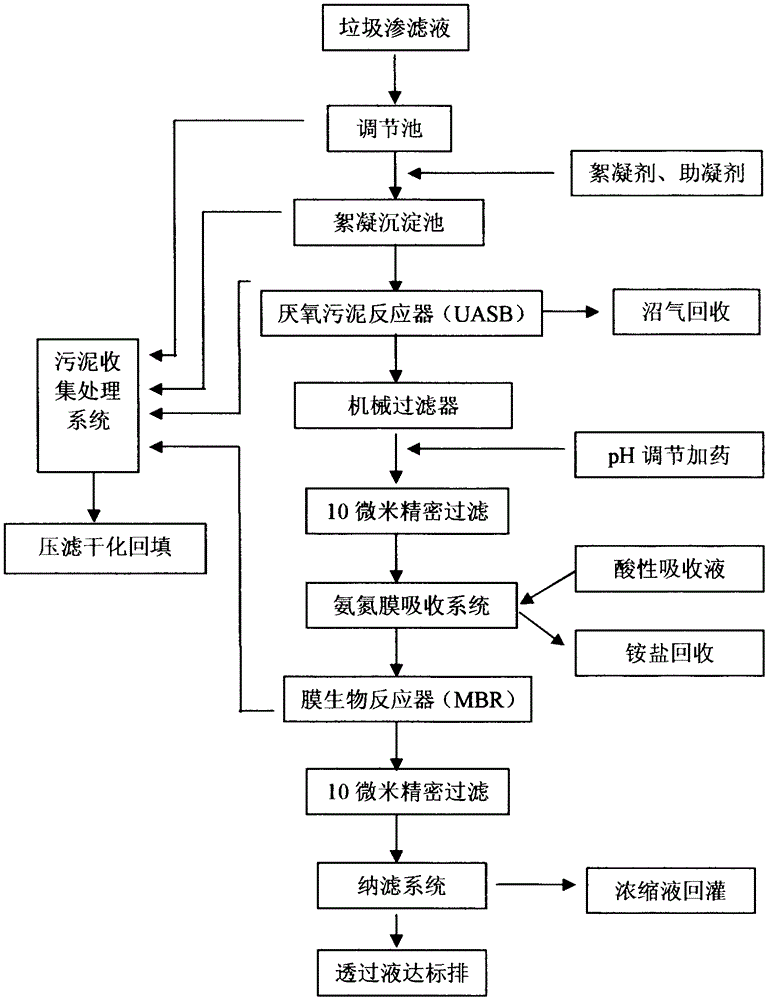

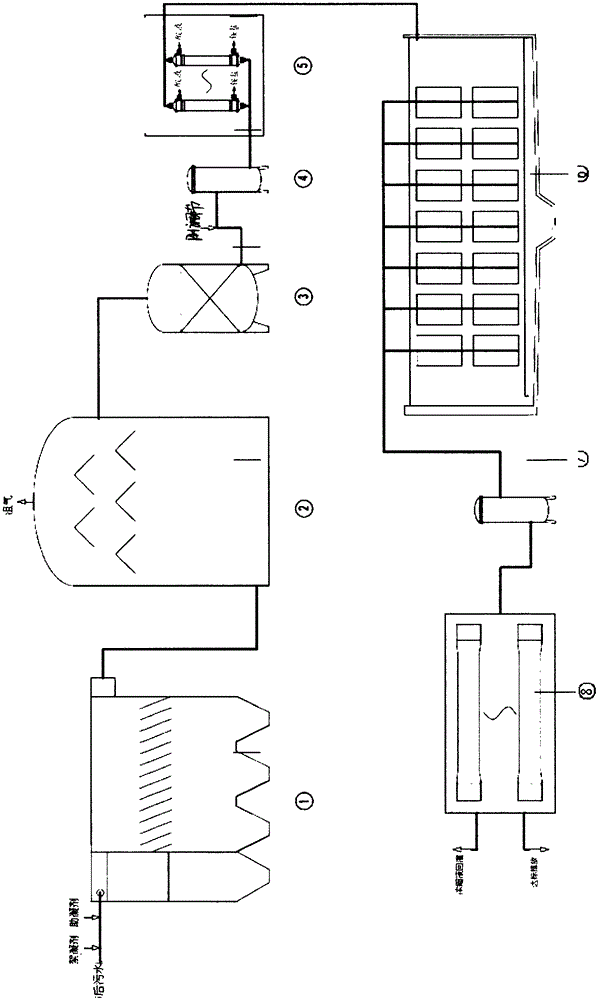

[0029] Embodiment 1, one of landfill leachate treatment method, carry out according to following steps:

[0030] Step 1: Inject the collected landfill leachate into the wastewater regulating tank and stay in the regulating tank for 8 hours;

[0031] Step 2: After the landfill leachate is homogenized in the regulating tank, it enters the coagulation sedimentation tank 1, and 25 mg of polyaluminium chloride and 1 mg of polyacrylamide are put into every liter of sewage;

[0032] The third step: the supernatant of the sedimentation tank enters the upflow anaerobic sludge bed reactor 2;

[0033] Step 4: The supernatant of the anaerobic sludge bed reactor 2 passes through the mechanical filter 3 to reduce the turbidity to less than 20 mg per liter, and adjust the pH to 10.5 after filtering;

[0034] Step 5: The above-mentioned sewage is filtered through a 10-micron A precision filter 4 to remove 10-micron suspended solids, and then enters the ammonia nitrogen absorption membrane sy...

Embodiment 2

[0043] Embodiment 2, the second of landfill leachate treatment method, carry out according to following steps:

[0044] Step 1: Inject the collected landfill leachate into the wastewater regulating tank and stay in the regulating tank for 12 hours;

[0045] Step 2: After the landfill leachate is homogenized in the regulating tank, it enters the coagulation sedimentation tank 1, and 15 mg of polyaluminium chloride and 3 mg of polyacrylamide are put into every liter of sewage;

[0046] The third step: the supernatant of the sedimentation tank enters the upflow anaerobic sludge bed reactor 2;

[0047] Step 4: The supernatant of the anaerobic sludge bed reactor 2 passes through the mechanical filter 3 to reduce the turbidity to less than 20 mg per liter, and adjust the pH to 10 after filtering;

[0048] Step 5: The above-mentioned sewage is filtered through a 10-micron A precision filter 4 to remove 10-micron suspended solids, and then enters the ammonia nitrogen absorption membr...

Embodiment 3

[0057] Embodiment 3, the third of landfill leachate treatment method, carry out according to following steps:

[0058] The first step: inject the collected landfill leachate into the wastewater regulating tank, and stay in the regulating tank for 15 hours;

[0059] Second step: after the landfill leachate is homogenized by the above-mentioned regulating tank, it enters the coagulation sedimentation tank 1, and 20 mg of polyaluminum chloride and 2 mg of polyacrylamide are dropped into every liter of sewage;

[0060] The third step: the above-mentioned sedimentation tank supernatant enters the upflow anaerobic sludge bed reactor 2 for reaction;

[0061] The fourth step: the supernatant produced by the upflow anaerobic sludge bed reactor is passed through the mechanical filter 3, and the turbidity is reduced to less than 20 mg / liter, and the pH is adjusted to 10.2 after filtering;

[0062] Step 5: The sewage is filtered through the 10 micron A precision filter 4, and the suspend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com