Carbon-coated titanium-doped stannic oxide material, manufacturing method and application thereof

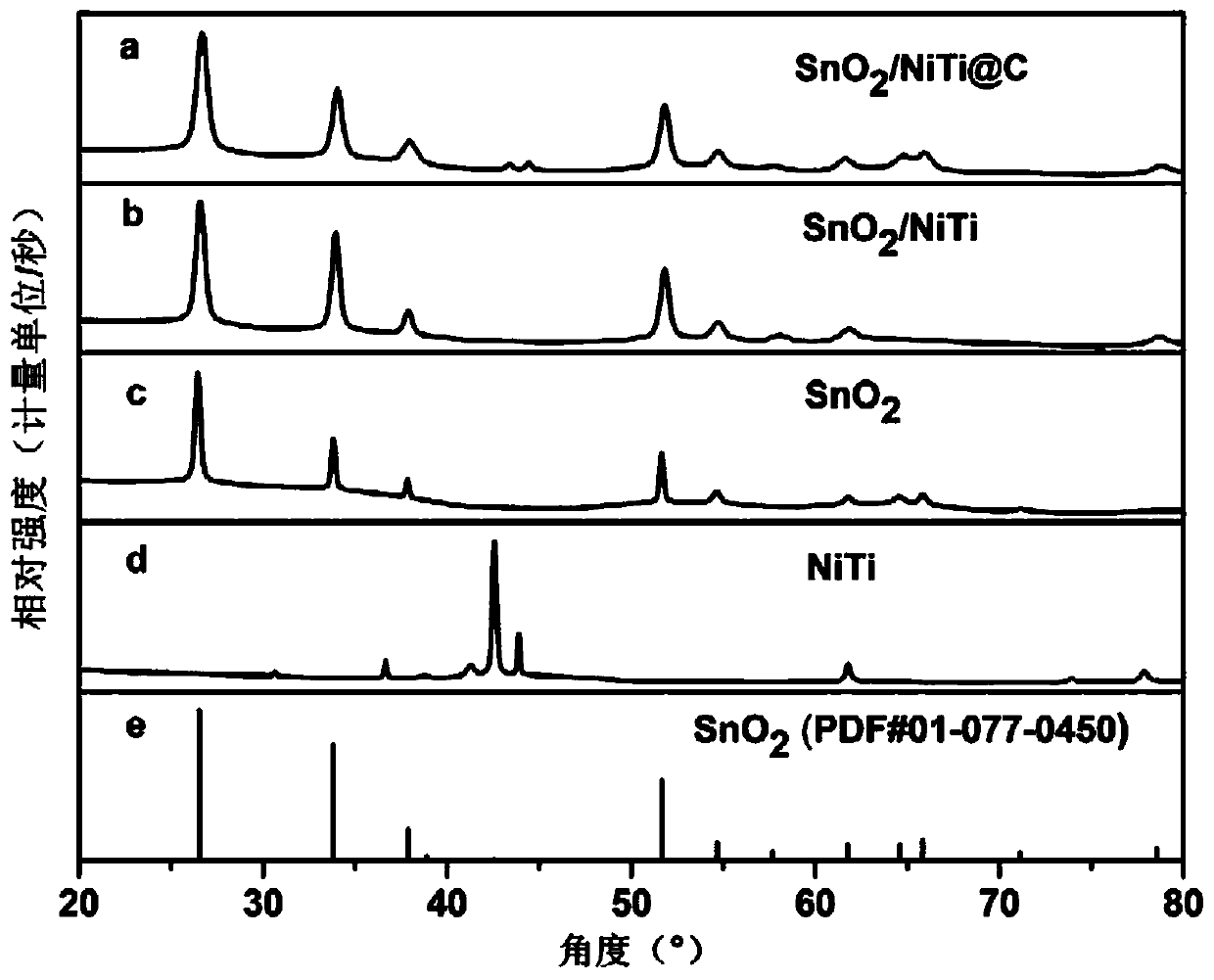

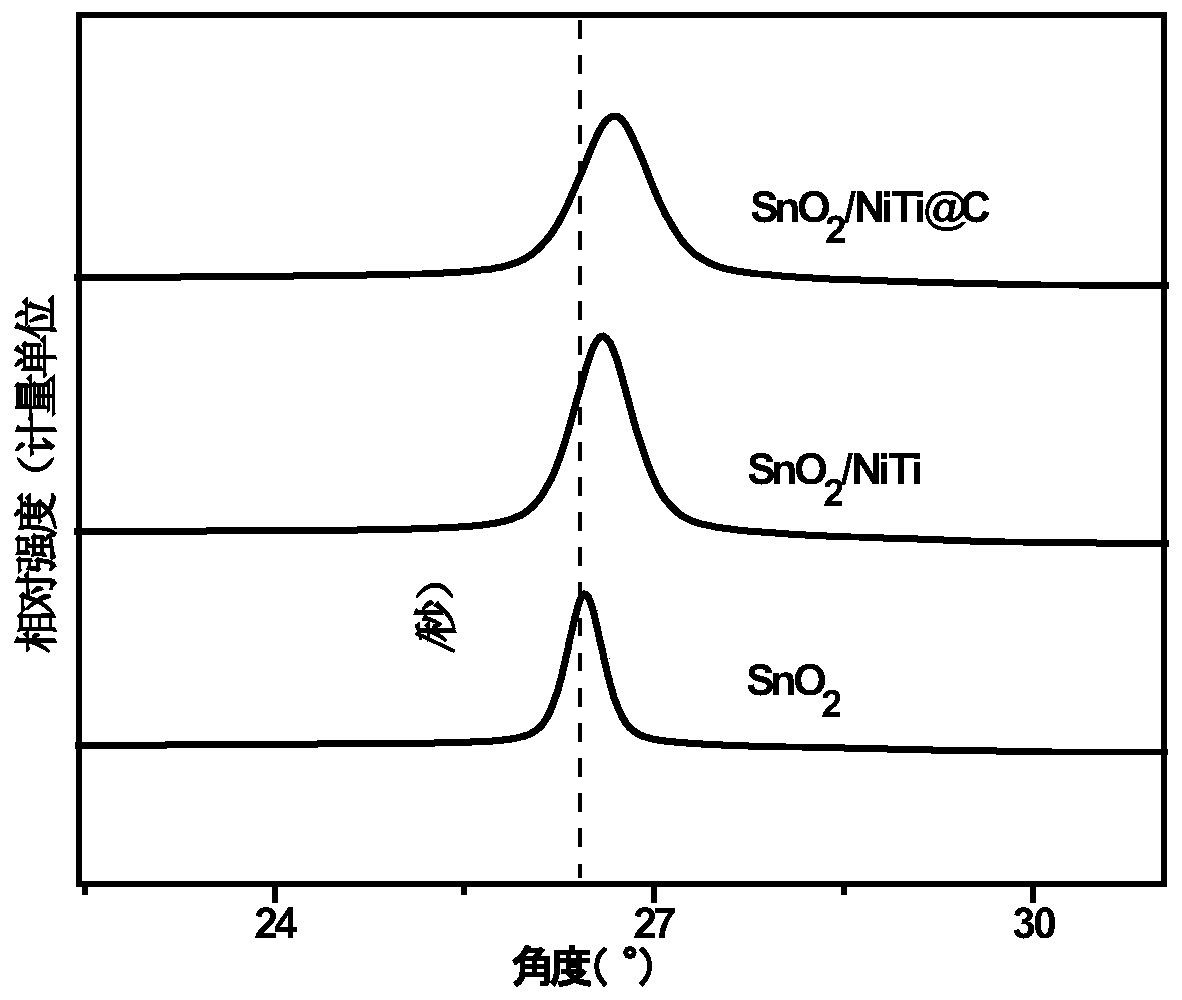

A tin dioxide and titanium doping technology, applied in secondary batteries, electrochemical generators, active material electrodes, etc., can solve the problems of poor reversibility and poor cycle stability of tin dioxide conversion reaction, and achieve easy scale-up Effects of production, buffering volume expansion, enhancing intrinsic conductivity, and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing a carbon-coated titanium-doped tin dioxide material, comprising the following steps:

[0055] (1) The analytically pure 1.07g SnSO 4 Dissolve in 100mL deionized water, and magnetically stir at 200 rpm for 30 minutes, and stir evenly to obtain solution A;

[0056] (2) Under magnetic stirring, add 9mL dropwise to the solution A obtained in step (1), 5% H 2 SO 4 , and stirred at 250 rpm for 2 minutes, and stirred evenly to obtain solution B;

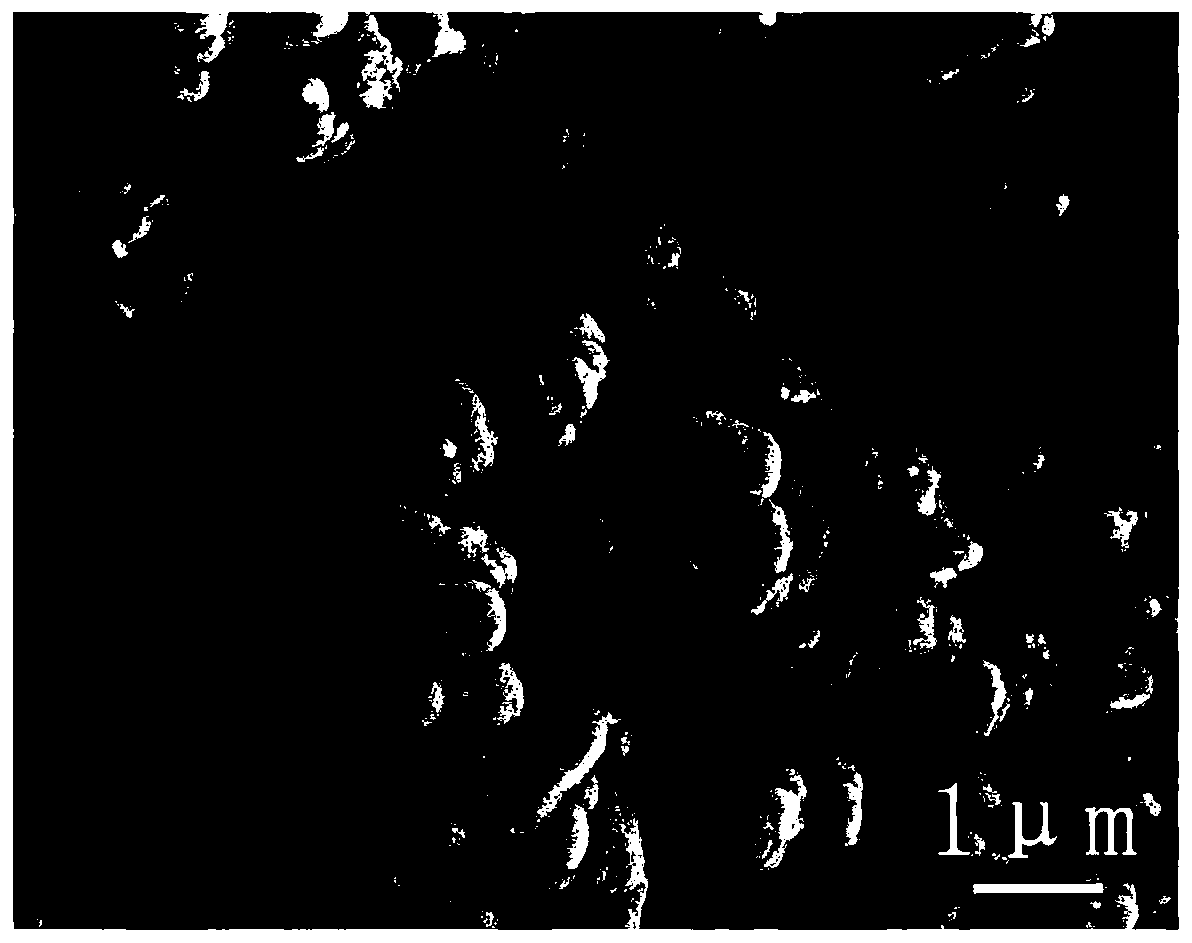

[0057] (3) under magnetic stirring, add 0.161g in step (2) gained solution B, the spherical NiTi alloy (the mass percent of Ni in the alloy composition is 55%) powder of 60nm, and stir 30 minutes with 250 revs / min, Stir evenly to obtain solution C;

[0058] (4) Under magnetic stirring, add 2 g of glucose to solution C obtained in step (3), stir at 250 rpm for 60 minutes, and stir evenly to obtain solution D;

[0059] (5) The solution D obtained in step (4) was transferred to a tetrafluoroethylene-lined aut...

Embodiment 2

[0075] A method for preparing a carbon-coated titanium-doped tin dioxide material, comprising the following steps:

[0076] (1) The analytically pure 1g SnSO 4 Dissolve in 100mL deionized water, and magnetically stir at 400 rpm for 30 minutes, and stir evenly to obtain solution A;

[0077] (2) Under magnetic stirring, add 12mL dropwise to the solution A obtained in step (1), H with a solubility of 8% 2 SO 4 , and stirred at 400 rpm for 3 minutes, and stirred evenly to obtain solution B;

[0078] (3) under magnetic stirring, add 0.3g in step (2) gained solution B, the spherical NiTi alloy (the mass percentage of Ni in the alloy composition is 56%) powder of 120nm, and stir 25 minutes with 420 revs / min, Stir evenly to obtain solution C;

[0079] (4) Under magnetic stirring, add 1.5 g of glucose to solution C obtained in step (3), and stir at 480 rpm for 50 minutes, and stir evenly to obtain solution D;

[0080] (5) The solution D obtained in step (4) was transferred to a te...

Embodiment 3

[0088] A method for preparing a carbon-coated titanium-doped tin dioxide material, comprising the following steps:

[0089] (1) The analytically pure 2g SnSO 4 Dissolve in 100mL deionized water, and stir magnetically at 300 rpm for 30 minutes, and stir evenly to obtain solution A;

[0090] (2) Under magnetic stirring, add 15mL dropwise to the solution A obtained in step (1), H with a solubility of 3% 2 SO 4 , and stirred at 300 rpm for 2 minutes, and stirred evenly to obtain solution B;

[0091] (3) under magnetic stirring, add 0.2g in step (2) gained solution B, the spherical NiTi alloy (the mass percentage of Ni in the alloy composition is 54%) powder of 80nm, and stir 30 minutes with 360 revs / min, Stir evenly to obtain solution C;

[0092] (4) Under magnetic stirring, add 5 g of glucose to solution C obtained in step (3), and stir at 390 rpm for 60 minutes, and stir evenly to obtain solution D;

[0093] (5) The solution D obtained in step (4) was transferred to a tetra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com