Multi-level double-pore structure composite photocatalyst, preparation and application thereof

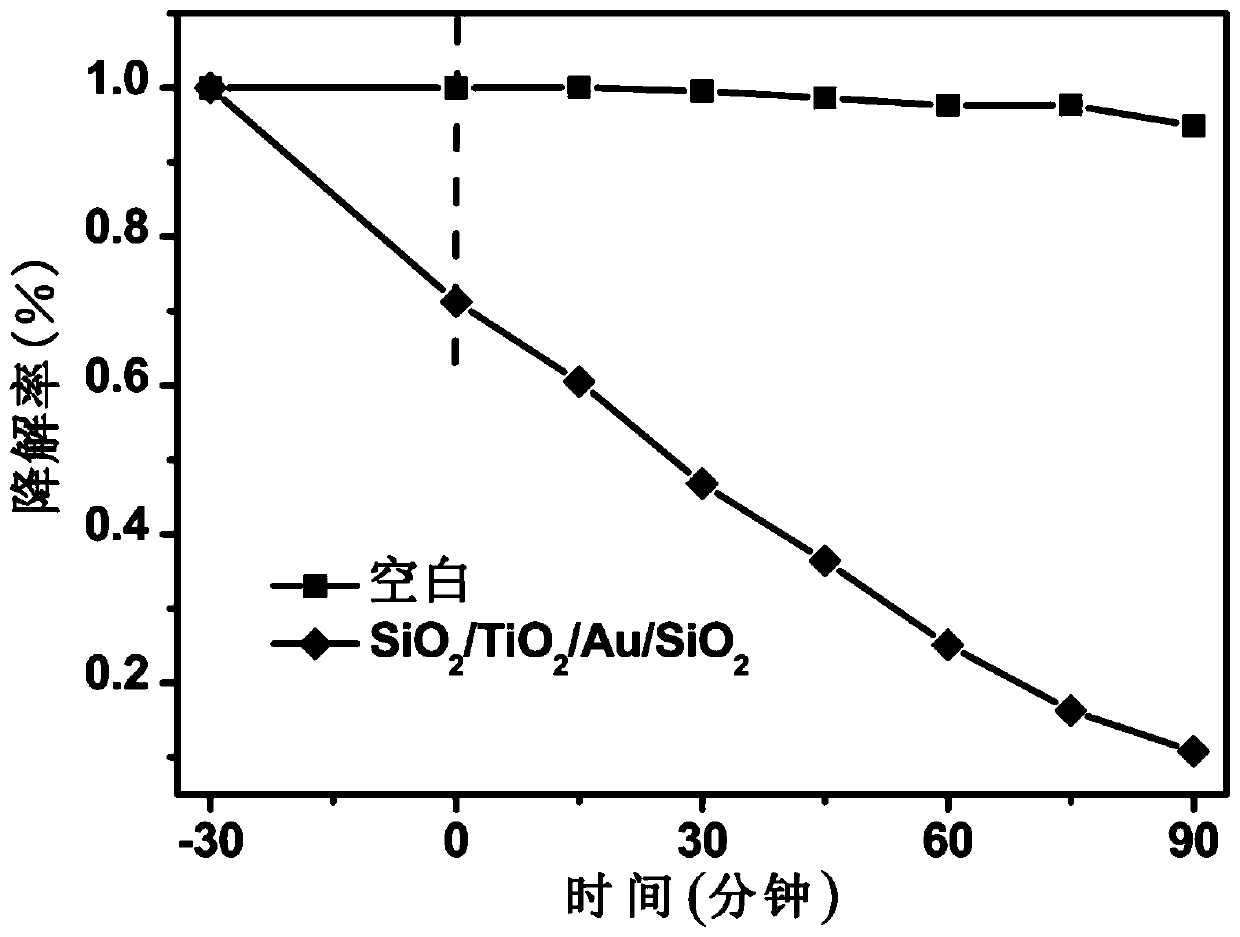

A composite photocatalyst technology, applied in the direction of heterogeneous catalyst chemical elements, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of difficult reuse and low solar energy utilization rate of photocatalysts and other problems, to achieve the effect of repeated and efficient use, easy centrifugation and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) TiO modified with oleic acid 2 Preparation of nanoparticles

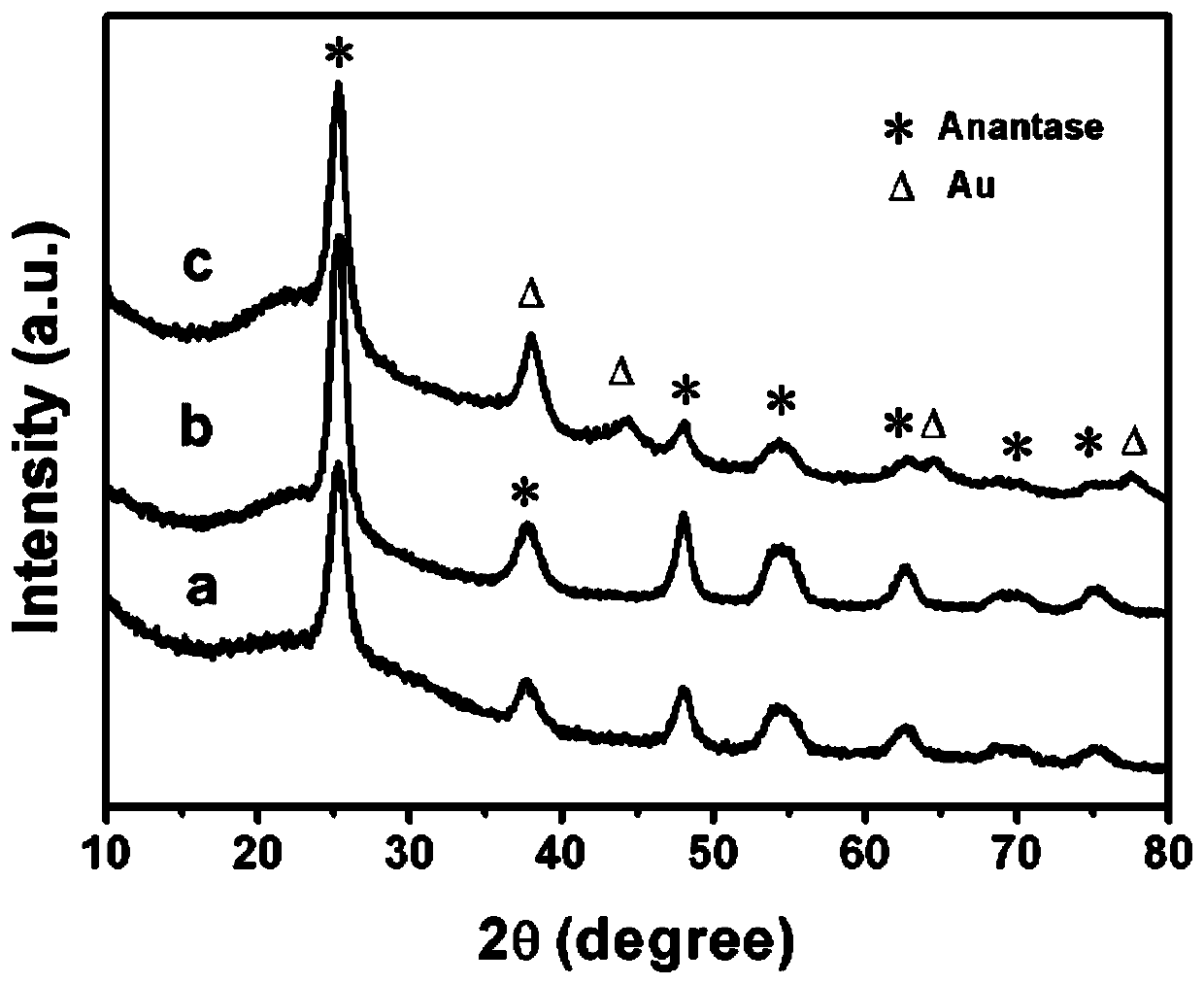

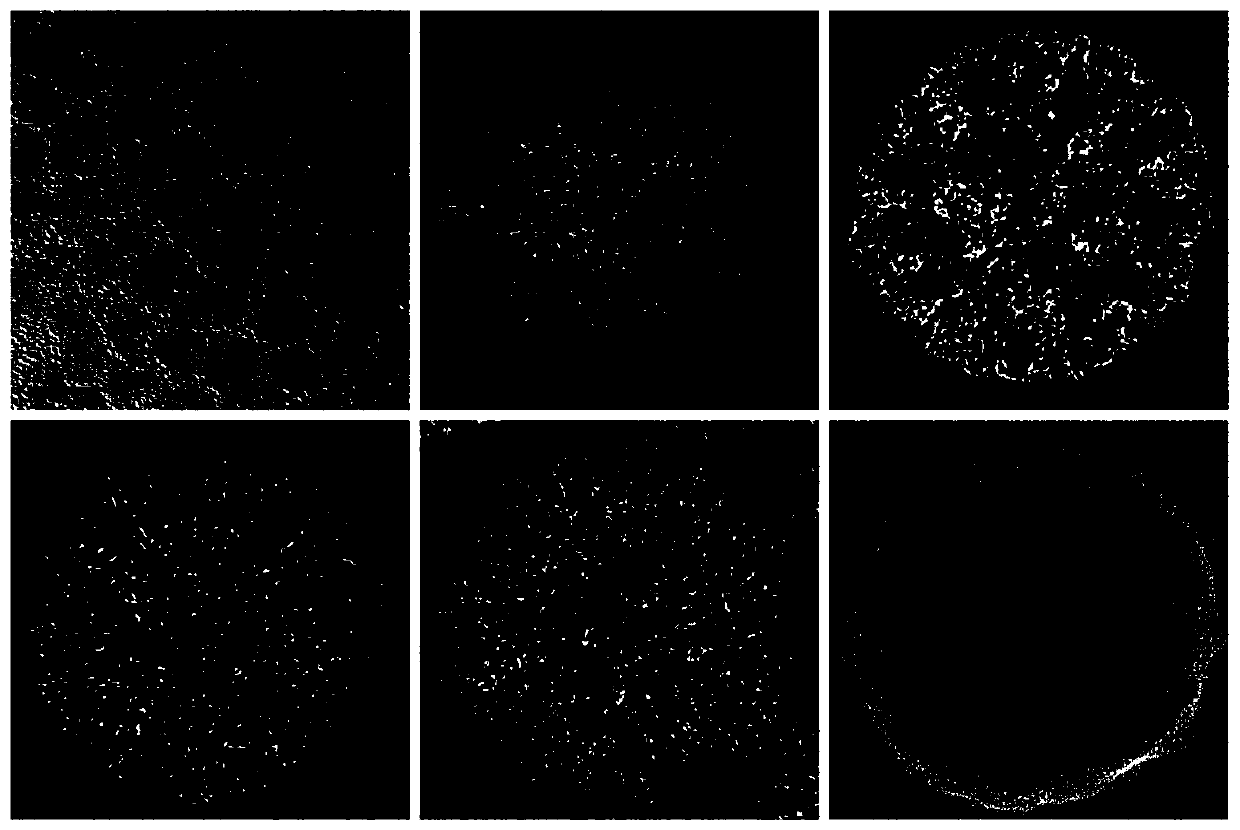

[0035] Add 4.53ml oleylamine, 8.75ml oleic acid, 3.43ml absolute ethanol, 1.021ml tetrabutyl titanate into a 50ml beaker, stir for 10min, then transfer to 50ml containing 11.77ml ethanol aqueous solution (volume concentration is 96%) In a tetrafluoroethylene-lined stainless steel reactor, react at 180°C for 14h. After the reaction, wash 3 times with absolute ethanol to obtain oleic acid-modified TiO 2 Nanoparticles 0.273g, the average particle size is 7.52nm, XRD figure see figure 1 As shown in the middle curve a, the transmission electron microscope picture is shown in figure 2 Shown in a, and then dispersed in 30ml of toluene.

[0036] (2) Thiolated dendritic mesoporous SiO 2 preparation of

[0037] Dissolve 0.068g TEA in 25ml water, stir magnetically in an oil bath at 80°C for 30min, then add 0.38gCTAB and 0.218g NaSal and stir for 1h, then add 4ml TEOS, react for 3h, after the reaction, wash the...

Embodiment 2

[0043] (1) TiO modified with oleic acid 2 Preparation of nanoparticles

[0044] Add 4.53ml oleylamine, 8.75ml oleic acid, 3.43ml absolute ethanol, 1.021ml tetrabutyl titanate into a 50ml beaker, stir for 10min, then transfer to 50ml containing 11.77ml ethanol aqueous solution (volume concentration is 96%) In a tetrafluoroethylene-lined stainless steel reactor, react at 180°C for 18h. After the reaction, wash 3 times with absolute ethanol to obtain oleic acid-modified TiO 2 0.316 g of nanoparticles, with an average particle diameter of 11.3 nm, was dispersed in 30 ml of toluene.

[0045] (2) Thiolated dendritic mesoporous SiO 2 preparation of

[0046] Dissolve 0.068g TEA in 25ml water, stir magnetically in an oil bath at 80°C for 30min, then add 0.38gCTAB and 0.168g NaSal and stir for 1h, then add 4ml TEOS, react for 4h, after the reaction, wash the product 3 times with absolute ethanol , then dissolved in 100ml of a mixed solution of hydrochloric acid and methanol (volume ...

Embodiment 3

[0052] (1) TiO modified with oleic acid 2 Preparation of nanoparticles

[0053] Add 4.53ml oleylamine, 10.5ml oleic acid, 3.43ml absolute ethanol, 1.021ml tetrabutyl titanate into a 50ml beaker, stir for 10min, then transfer to 50ml containing 11.77ml ethanol aqueous solution (volume concentration is 96%) In a tetrafluoroethylene-lined stainless steel reactor, react at 180°C for 14h. After the reaction, wash 3 times with absolute ethanol to obtain oleic acid-modified TiO 2 0.398 g of nanoparticles, with an average particle diameter of 10.3 nm, was dispersed in 30 ml of toluene.

[0054] (2) Thiolated dendritic mesoporous SiO 2 preparation of

[0055] Dissolve 0.068g TEA in 25ml water, stir magnetically in an oil bath at 80°C for 30min, then add 0.38gCTAB and 0.168g NaSal and stir for 1h, then add 4ml TEOS, react for 3h, after the reaction, wash the product 3 times with absolute ethanol , then dissolved in 100ml of a mixed solution of hydrochloric acid and methanol (volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com