Preparation method of Co9S8/MoS2 multilevel structure composite material

A composite material and precursor solution technology, applied in the field of nanomaterials, can solve the problems of difficult to prepare multi-level structure materials of composite components, complex preparation process of multi-level structure, and cumbersome process, so as to improve electrochemical performance, maintain stability and Dimensional uniformity and high production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

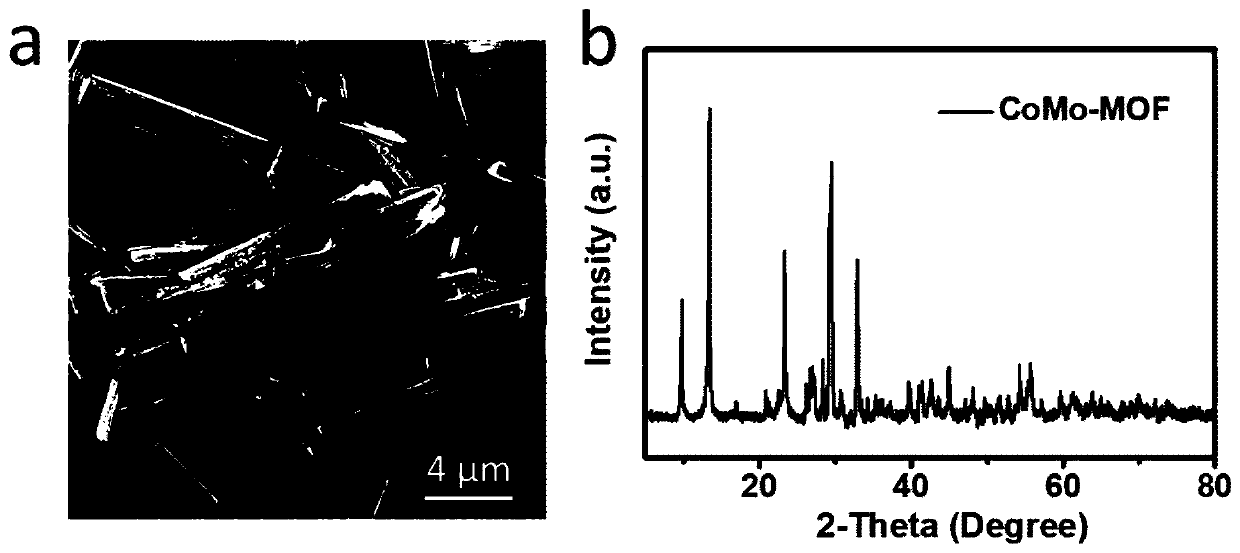

[0048] A kind of Co 9 S 8 / MoS 2 The preparation method of multi-level structure composite material,

[0049] The preparation method comprises the following preparation steps:

[0050] 1) Add 5gMoO 3 Add it to 250mL deionized water, add 4.75g 2-methylimidazole to ultrasonically dissolve to form A solution, then weigh 2.6g Co(NO 3 ) 2 ·6H 2 O was added into 250mL deionized water and ultrasonically dissolved to form liquid B, and liquid A and liquid B were mixed to prepare a precursor solution, and then the precursor solution was heated in an oil bath at 120°C for 12 hours, cooled to room temperature after the reaction, centrifuged and filtered. The CoMo-MOF material was obtained by washing three times, and dried under vacuum at 60°C for 12 hours;

[0051] 2) Dissolve 50mg of thioacetamide in 50mL of ethanol to prepare an organic solvent, weigh 8.25mg of CoMo-MOF material and disperse it in an organic solvent to prepare a dispersion liquid, and then conduct a hydrothermal...

Embodiment 2

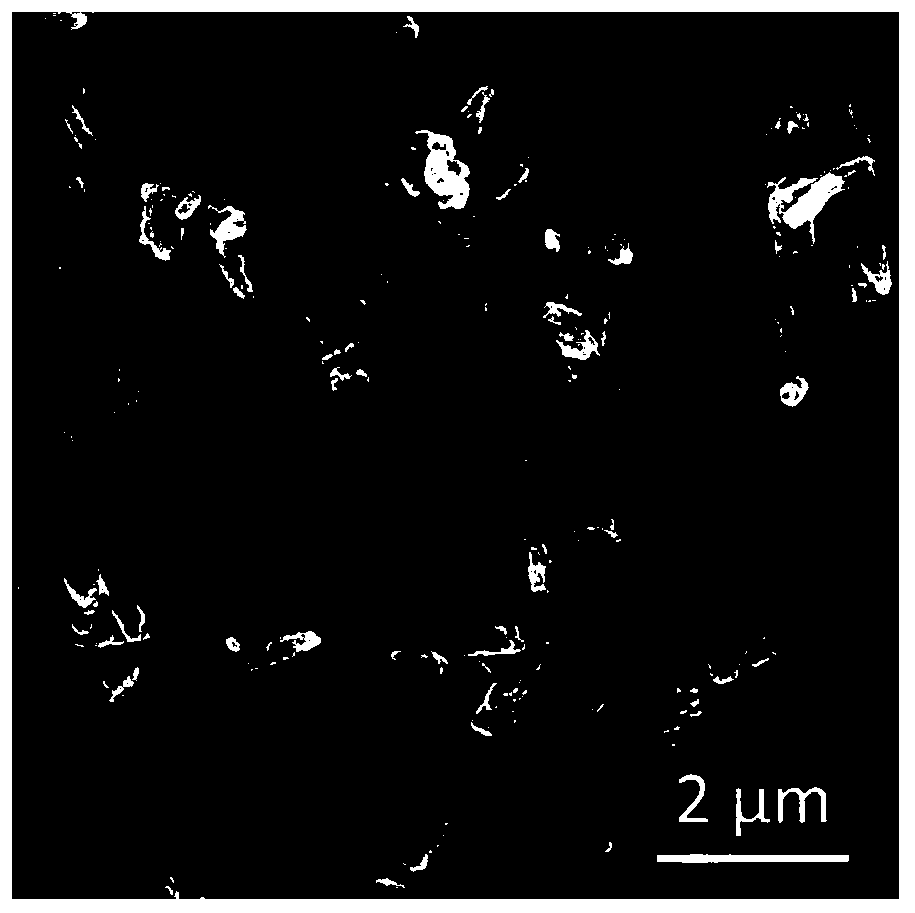

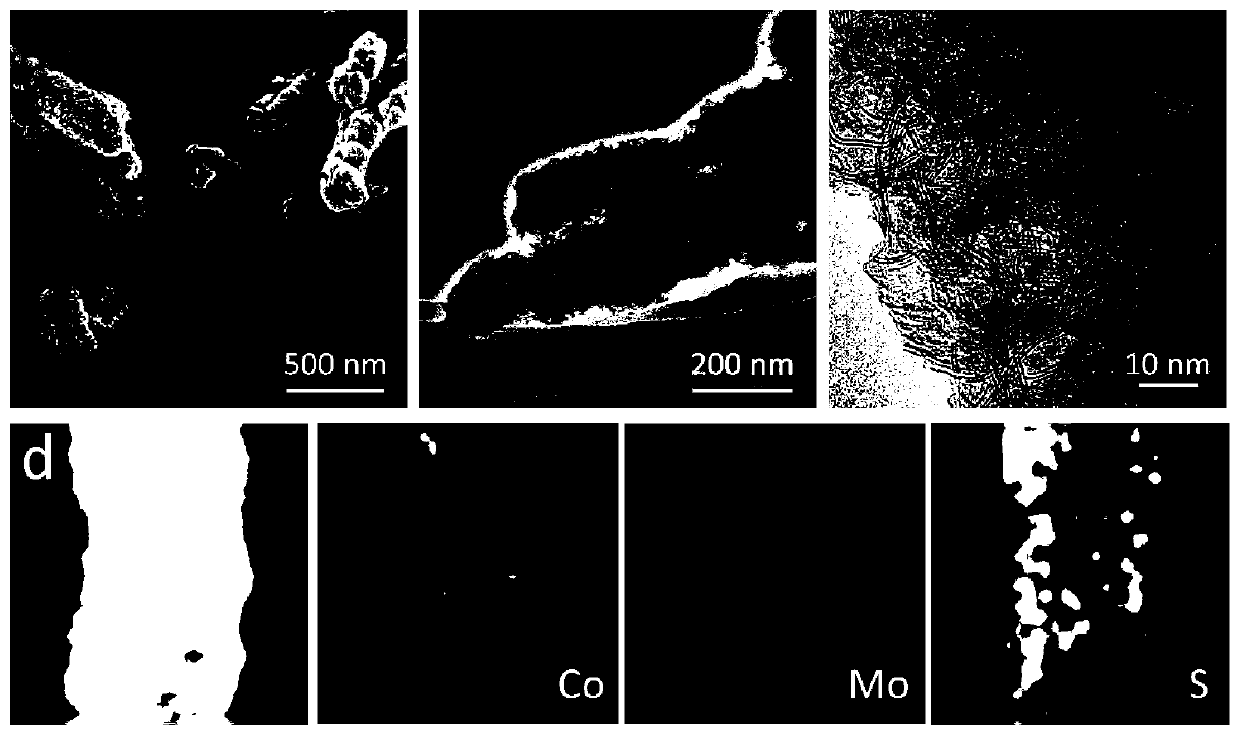

[0068] Concrete steps are identical with embodiment 1, difference is: MoO 3 The dosage is 0.36g, Co(NO 3 ) 2 ·6H 2 The amount of O was 6.54 g, the amount of 2-methylimidazole was 2.05 g, the temperature of the oil bath was 80° C., and the duration of the oil bath was 18 h. to Co 9 S 8 / MoS 2 The multi-level structure composite powder was characterized by SEM, and the characterization results showed that it was a hollow rod-like structure with Co 9 S 8 and MoS 2 The nanosheets are vertically distributed on the surface of the nanorods.

Embodiment 3

[0070] Concrete steps are identical with embodiment 1, difference is: MoO 3 The dosage is 3.60g, Co(NO 3 ) 2 ·6H 2 The amount of O used was 65.49 g, the amount of 2-methylimidazole was 20.53 g, the temperature of the oil bath was 180° C., and the duration of the oil bath was 8 h. to Co 9 S 8 / MoS 2 The multi-level structure composite powder was characterized by SEM, and the characterization results showed that it was a hollow rod-like structure with Co 9 S 8 and MoS 2 The nanosheets are vertically distributed on the surface of the nanorods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com