Method for preparing zirconium metal organic framework (Zr-MOF) nanotubes

A metal-organic framework, nanotube technology, applied in nanotechnology, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., to achieve good chemical stability, excellent photoluminescence performance, and simple steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing zirconium metal organic framework nanotubes of the present invention, comprising the following steps:

[0026] Dissolve the zirconium metal salt in the solvent DMF, and add 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene and regulator, then carry out ultrasonic or stirring dispersion, and then carry out solvothermal heat to the mixture obtained after dispersion treatment After the reaction, cool to room temperature after the reaction is completed, wash and dry to a completely dry state to obtain Zr-MOF nanotubes. The method of the present invention avoids the traditional preparation of MOF nanotubes with complex structures using an external template agent, and can directly obtain Zr-MOF nanotubes through a one-step reaction.

[0027] The metal salt is preferably a metal salt of zirconium (IV), such as zirconium chloride, zirconium oxychloride and the like.

[0028] The ratio of the amount of zirconium metal salt to 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene...

Embodiment 1

[0038] A method for preparing zirconium metal organic framework nanotubes of the present invention, comprising the following steps:

[0039] Weigh 135mg ZrOCl 2 ·8H 2 O (0.42mmol), 191mg 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene (0.28mmol) in a 100mL microwave reactor, add 10mL N,N-dimethylformamide, 0.2mL formic acid and 0.3mL of deionized water, stirred and dissolved fully, placed in a microwave reactor, microwave solvothermal reaction at 120°C for 90min, cooled to room temperature, the resulting product was subjected to N,N-dimethylformamide, ethanol, deionized After washing with water three times, the Zr-MOF nanotubes were obtained by vacuum drying at 60°C.

Embodiment 2

[0041] A method for preparing zirconium metal organic framework nanotubes of the present invention, comprising the following steps:

[0042] 53.7mg ZrOCl 2 ·8H 2 O was dissolved in 1 mL of DMF, and after it was completely dissolved, 99.7 mg of 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene was added, followed by 71.2 mg of benzoic acid and 25 μL of deionized water, and ultrasonically dispersed for 15 Minutes later, the mixture was reacted under solvothermal conditions at 120° C. for 24 hours. After cooling to room temperature, the obtained product was washed with DMF, absolute ethanol, and water three times respectively, and then dispersed in water. Finally, it was dried in a freeze dryer until completely dry to obtain Zr-MOF nanotubes.

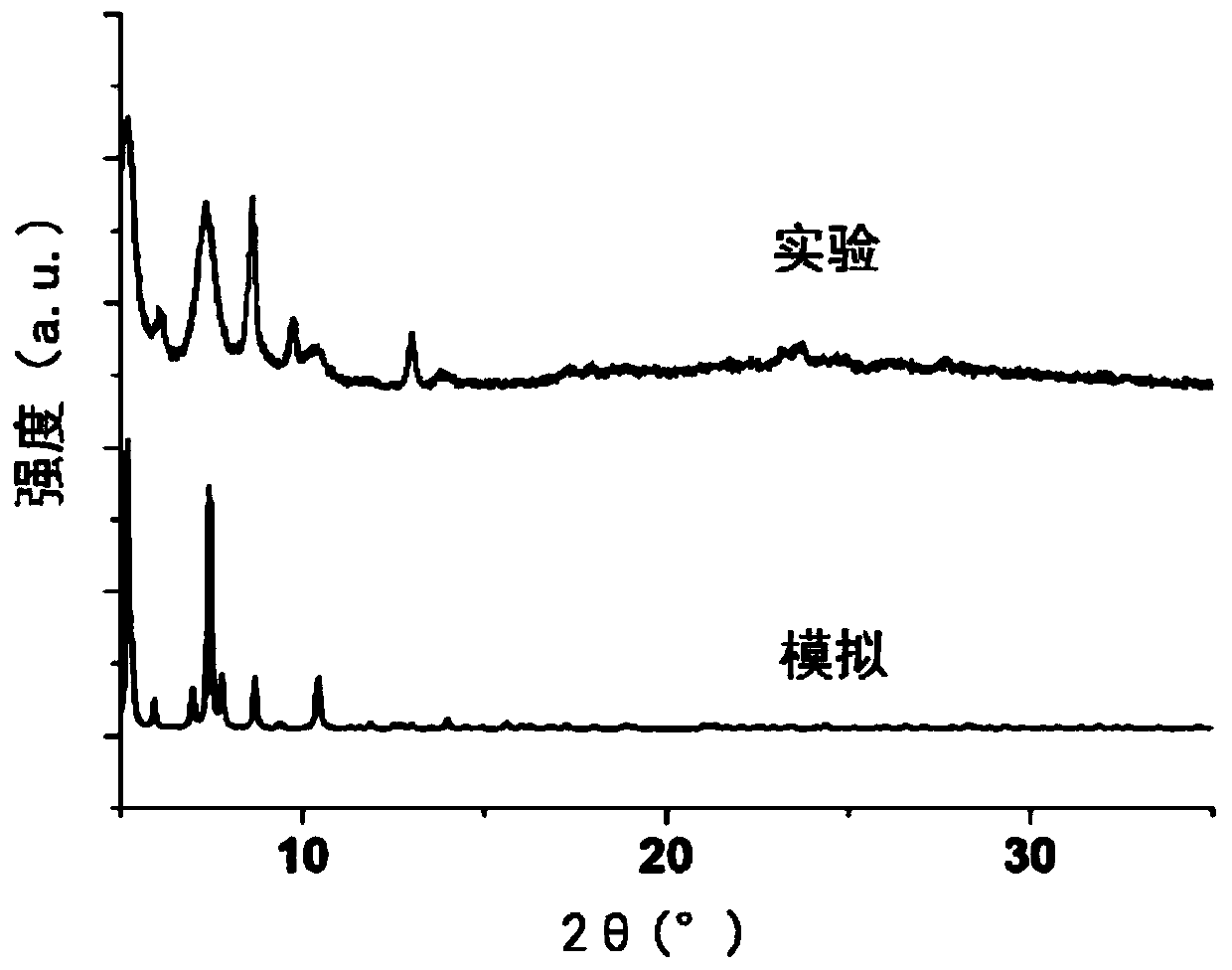

[0043] To the characterization data of the gained nanotube of embodiment 2 such as Figure 1-3 shown. figure 1 and figure 2 It is the microscopic morphology of the product under 10,000 and 20,000 times magnification respectively. It can be see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com