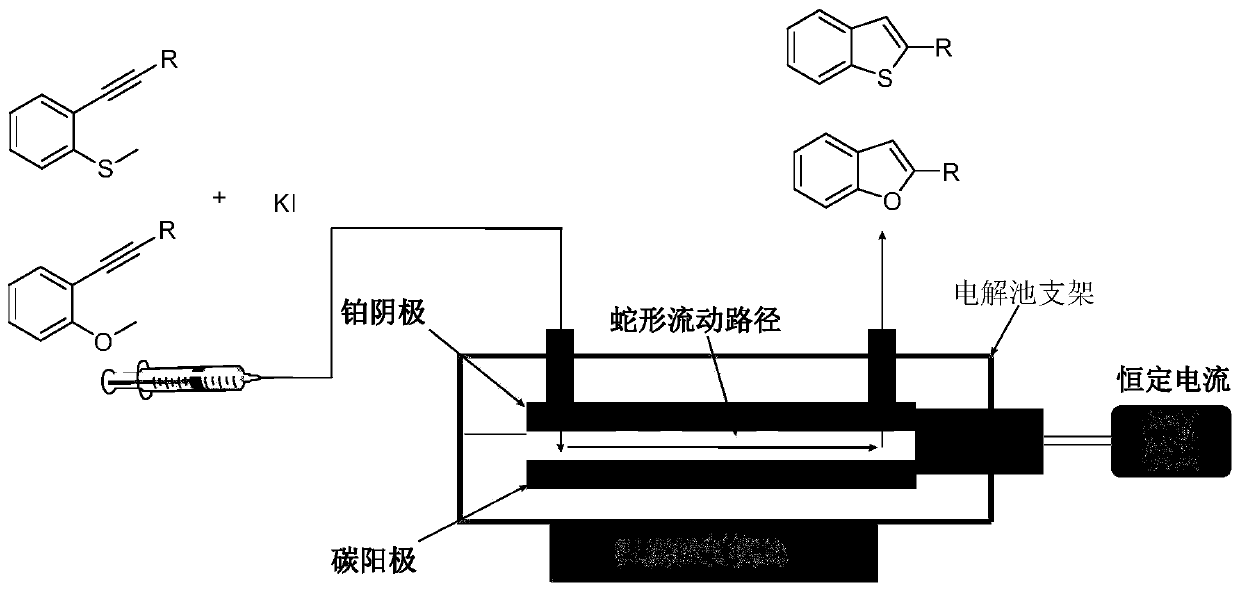

Method for continuously preparing 2-aryl-benzothiophene/furan compound by utilizing electrochemical micro-channel reaction device

A technology of microchannel reaction and benzothiophene, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high reactor design requirements, poor selectivity, environmental pollution, etc., and achieve good industrial application prospects and reaction temperature Low, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

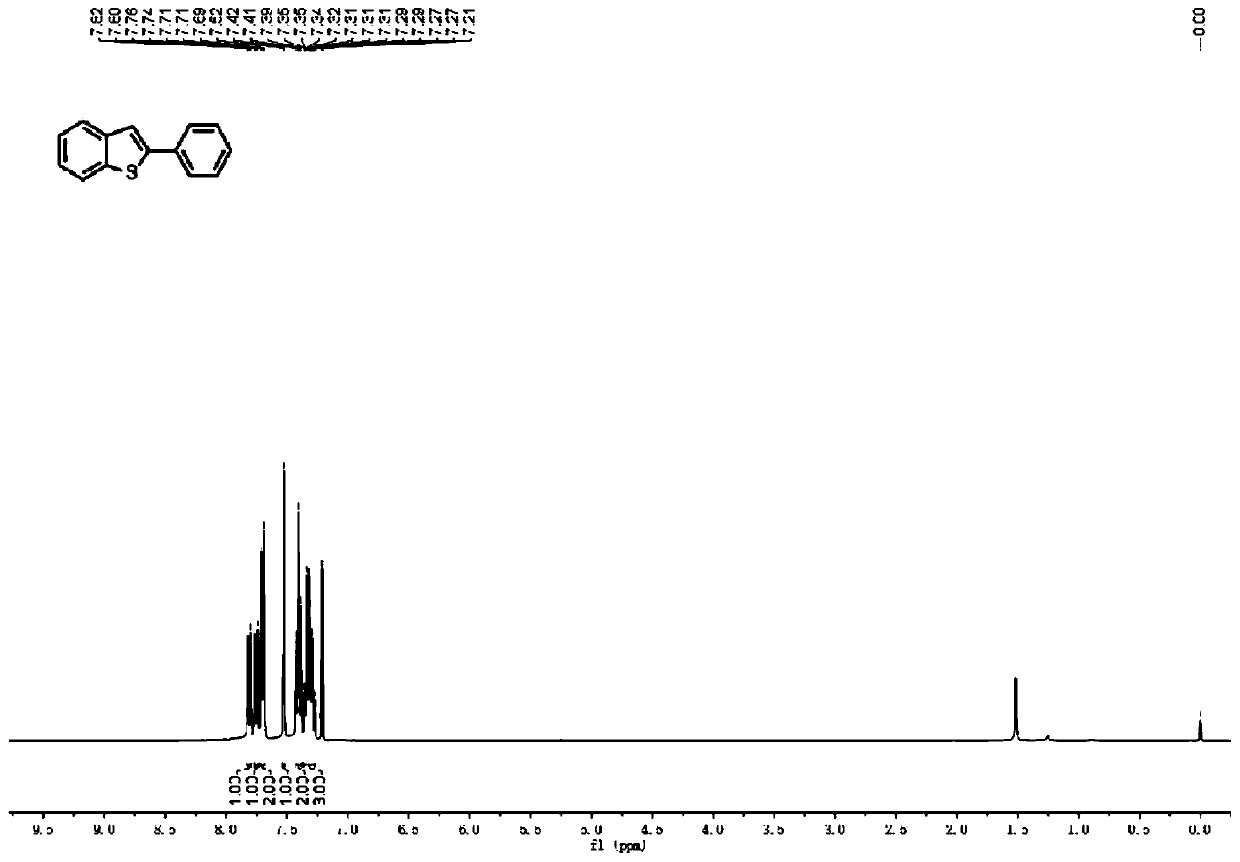

[0035] Assemble the electrochemical flow cell device: select the carbon sheet as the anode electrode, place it on the lower layer of the titanium alloy electrolytic cell bracket, and then place the PTFE reaction tank with a volume of 0.5ml on the upper layer of the carbon sheet, and then plate the cathode with platinum The titanium alloy plate is placed on the upper layer of the reaction tank, and finally fixed with a polytetrafluoroethylene screw and connected to an adjustable DC power supply. Weigh 0.045g of 2-phenylethynylanisole sulfide and 0.0332g of KI and dissolve them in 1ml of water and 5ml of acetonitrile to prepare a homogeneous solution A. The prepared homogeneous solution A was passed into the reaction module with a single-stream injection at a flow rate of 0.02 ml / min using a syringe pump. Turn on the power supply, adjust the current to 20mA, and collect the product 2-phenyl-benzothiophene from the outlet of the reaction module after it stabilizes.

[0036] NMR ...

Embodiment 2

[0038]Assemble the electrochemical flow cell device: select the carbon sheet as the anode electrode, place it on the lower layer of the titanium alloy electrolytic cell bracket, and then place the PTFE reaction tank with a volume of 0.5ml on the upper layer of the carbon sheet, and then plate the cathode with platinum The titanium alloy plate is placed on the upper layer of the reaction tank, and finally fixed with a polytetrafluoroethylene screw and connected to an adjustable DC power supply. Weigh 0.045g of 2-phenylethynylanisole sulfide and 0.03g of NaI and dissolve them in 1ml of water and 5ml of acetonitrile to prepare a homogeneous solution A. The prepared homogeneous solution A was passed into the reaction module with a single-stream injection at a flow rate of 0.02 ml / min using a syringe pump. Turn on the power supply, adjust the current to 20mA, and collect the product 2-phenyl-benzothiophene from the outlet of the reaction module after it stabilizes.

Embodiment 3

[0040] Assemble the electrochemical flow cell device: select the carbon sheet as the anode electrode, place it on the lower layer of the titanium alloy electrolytic cell bracket, and then place the PTFE reaction tank with a volume of 0.5ml on the upper layer of the carbon sheet, and then plate the cathode with platinum The titanium alloy plate is placed on the upper layer of the reaction tank, and finally fixed with a polytetrafluoroethylene screw and connected to an adjustable DC power supply. Weigh 0.045g of 2-phenylethynylanisole sulfide and 0.074g of Bu 4 NI was dissolved in 1 ml of water and 5 ml of acetonitrile to make a homogeneous solution A. The prepared homogeneous solution A was passed into the reaction module with a single-stream injection at a flow rate of 0.02 ml / min using a syringe pump. Turn on the power supply, adjust the current to 20mA, and collect the product 2-phenyl-benzothiophene from the outlet of the reaction module after it stabilizes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com