High-strength air filter paper and preparation method thereof

An air filter paper, high-strength technology, applied in filter paper, special paper, filter separation, etc., can solve the problems of short filtration time, reduced service life of air filter paper, damp filter material, etc., achieve excellent antibacterial performance, increase flame retardancy effect, the effect of low filter resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

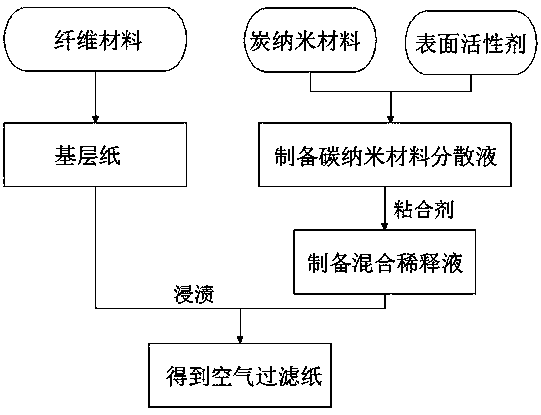

[0025] A preparation method of high-strength air filter paper, comprising the following steps:

[0026] (1) Prepare the base layer paper, mix the glass fiber material with water and fully decompose it in the decomposer, then dilute it with water to a mass concentration of 0.01-2%, to obtain the base layer fiber suspension, and then send the suspension to the former for molding, After suction, the base layer is formed into wet paper;

[0027] (2) preparing a carbon nanomaterial dispersion, adding carbon nanotubes with a diameter of 50 to 100 nm into a surfactant solution with a mass concentration of 0.05 wt%, and ultrasonically dispersing to obtain a carbon nanomaterial dispersion;

[0028] (3) Prepare a mixed diluent, mix the carbon nanomaterial dispersion and the binder, add water to configure the carbon nanomaterial dispersion and the binder in a total mass percentage of 0.5% mixed diluent;

[0029] (4) To obtain air filter paper, soak the molded wet paper obtained in step...

Embodiment 2

[0033] A preparation method of high-strength air filter paper, comprising the following steps:

[0034] (1) To prepare the base paper, mix the carbon fiber material with water and fully disintegrate it in the decomposer, then dilute it with water to a mass concentration of 1% to obtain the base fiber suspension, then send the suspension to the former for molding, after suction Obtain base-layer forming wet paper;

[0035] (2) preparing a carbon nanomaterial dispersion, adding carbon nanofibers with a maximum diameter of 300 nm into a surfactant solution with a mass concentration of 0.05 wt%, and ultrasonically dispersing to obtain a carbon nanomaterial dispersion;

[0036] (3) Prepare a mixed diluent, mix the carbon nanomaterial dispersion and the binder, add water to configure the carbon nanomaterial dispersion and the binder in a total mass percentage of 2% mixed diluent;

[0037] (4) To obtain air filter paper, soak the molded wet paper obtained in step (1) in the mixed d...

Embodiment 3

[0041] A preparation method of high-strength air filter paper, comprising the following steps:

[0042] (1) To prepare the base layer paper, mix the fiber material with water and fully decompose it in the decomposer, then dilute it with water to a mass concentration of 1% to obtain the base layer fiber suspension, then send the suspension to the former for molding, after suction Obtain base-layer forming wet paper;

[0043] (2) Prepare a carbon nanomaterial dispersion, adding carbon nanofibers with a maximum diameter of 300nm into a surfactant solution with a mass concentration of 5wt%, and ultrasonically dispersing to obtain a carbon nanomaterial dispersion;

[0044] (3) Prepare a mixed diluent, mix the carbon nanomaterial dispersion and the binder, add water to configure the carbon nanomaterial dispersion and the binder in a total mass percentage of 5% mixed diluent;

[0045] (4) To obtain air filter paper, soak the molded wet paper obtained in step (1) in the mixed diluen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com