Lithium ion battery positive electrode material and preparation method and application thereof

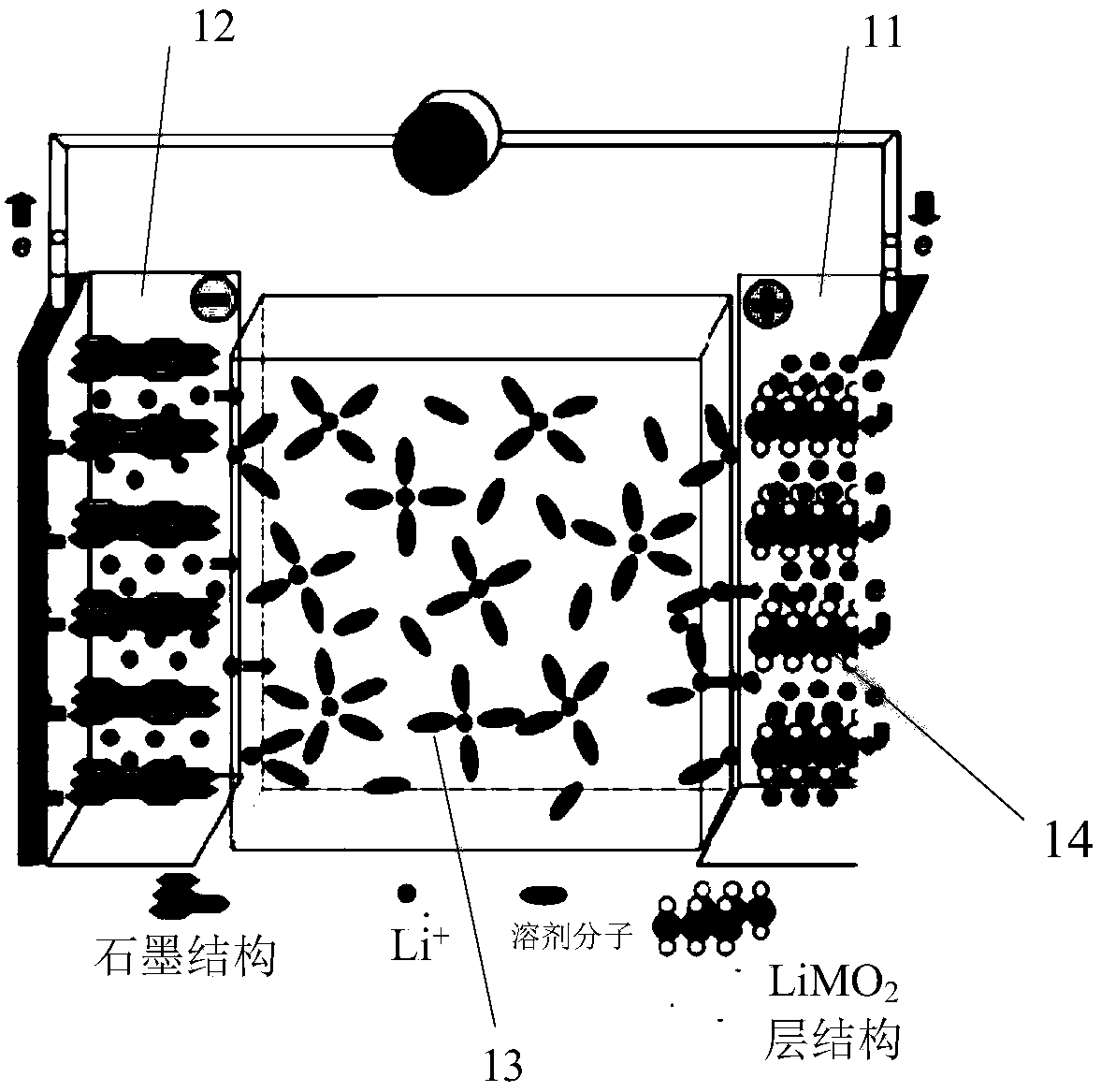

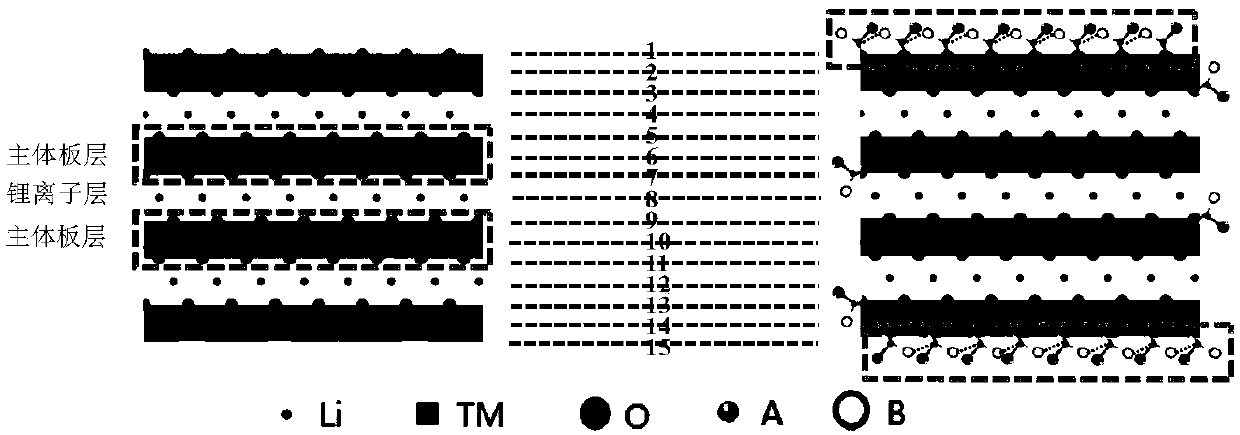

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, electrolyte storage battery manufacturing, secondary batteries, etc., can solve the problems affecting the capacity, rate and cycle performance of lithium-ion batteries, the increase in the valence state of transition metal elements, and the increase in interface impedance and other problems, to achieve the effects of alleviating the dissolution of transition metals and gas production, reducing side reactions, and reducing the increase in interfacial impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0113] Firstly, the preparation method of covering the coating layer on the surface of the positive electrode material substrate through the sintering process is introduced. The preparation method of this lithium ion battery cathode material may comprise the following steps:

[0114] Feed the lithium source, the transition metal source, and the material used to form the coating layer according to the molar ratio of each element in the chemical formula of the positive electrode material of the lithium ion battery, and stir and mix evenly to obtain a mixture;

[0115] placing the mixture in a heating furnace for sintering to obtain a sintered product;

[0116] The sintered product is crushed to obtain the positive electrode material of the lithium ion battery.

[0117] The preparation method of the cathode material of the lithium ion battery can be produced through one sintering process, and the process is relatively simple.

[0118] As an example, the positive electrode mater...

Embodiment 1

[0158] This embodiment provides a method to dope Li 0.95 La 0.05 CoO 2 As the core, the surface is covered with Al 2 o 3 The core-shell positive electrode material and the method of assembling it into a pouch battery:

[0159] 1) Preparation of doped lithium cobalt oxide matrix: Li 0.95 La 0.05 CoO 2

[0160] Take Li respectively 2 CO 3 ,Co 3 o 4 and La 2 o 3 , according to the molar ratio of lithium, cobalt, and lanthanum 1.06:1:0.05, stir and mix evenly, place in a muffle furnace or sintering furnace for temperature sintering, keep it at 1050°C for 12 hours, collect the product after natural cooling, and crush it Collected to obtain doped lithium cobaltate Li 0.95 La 0.05 CoO 2 .

[0161] 2) Doped lithium cobaltate Li 0.95 La 0.05 CoO 2 Preparation of core-shell cathode materials for primary particle matrix

[0162] Get the doped cobaltate lithium Li of step 1) preparation 0.95 La 0.05 CoO 2 20g, then infiltrated with ethanol and tiled onto a glass s...

Embodiment 2

[0166] This embodiment provides a method to dope Li 0.95 Al 0.04 La 0.01 CoO 2 As the core, the surface is covered with AlF 3 The core-shell positive electrode material and the method of assembling it into a pouch battery:

[0167] 1) Preparation of doped lithium cobalt oxide matrix: Li 0.95 Al 0.04 La 0.01 CoO 2

[0168] Take Li respectively 2 CO 3 ,Co 3 o 4 , La 2 o 3 and Al 2 o 3 , according to the molar ratio of lithium, cobalt, aluminum, and lanthanum 1.06:1:0.04:0.01, stir and mix evenly, then place it in a muffle furnace or sintering furnace for temperature sintering, keep it at 1050°C for 12 hours, and collect the product after natural cooling , and crushed and collected to obtain doped lithium cobaltate Li 0.95 Al0.04 La 0.01 CoO 2 .

[0169] 2) Doped lithium cobaltate Li 0.95 Al 0.04 La 0.01 CoO 2 Preparation of core-shell cathode materials for primary particle matrix

[0170] Get the doped cobaltate lithium Li of step 1) preparation 0.95 Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electronegativity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com